Light intensity signal measuring system in multi-phase optical catalytic reactor and method of use thereof

A technology for a photocatalytic reactor and a measuring system, which is applied in the field of measuring systems for light intensity fluctuation signals inside a heterogeneous photocatalytic reactor, can solve the problems of complex structure of the light intensity meter, cumbersome measuring methods, narrow measuring range, etc. Simple, easy to operate, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

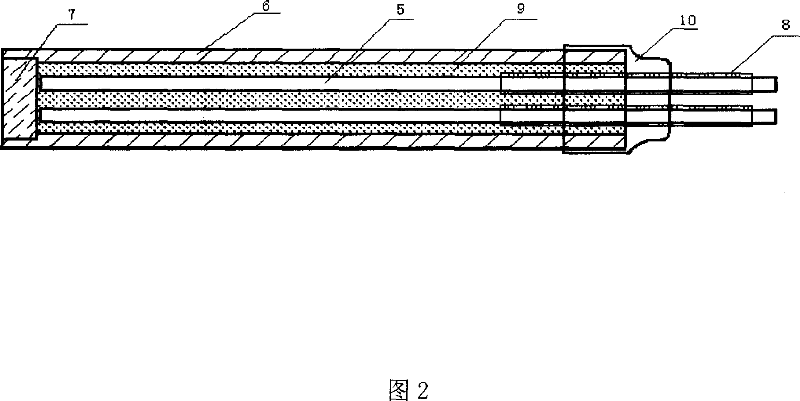

[0017] The light intensity sensor 1 of the present invention is a needle-shaped sensor made of a metal sleeve 6 with a diameter of 0.2-0.5mm and a metal sleeve 6 with a diameter of 1-2mm and a length of 200-500mm. There are scales marked, and the metal sleeve 6 is filled with sealant 9, so that the positions of the two bundles of optical fibers and the metal protective cover are relatively fixed. The end face of the light intensity sensor 1 is sealed with quartz glass 7 to make a miniature light intensity sensor 1. The other end of the light intensity sensor 1 is sealed with heat-shrinkable plastic 10 to protect the optical fibers from breaking. The two bundles of optical fibers are respectively covered with protective hoses 8 with a length of 1 to 2 m, and are respectively connected to the optical fiber sensors of the light intensity meter host 2 through joints. on interface 11.

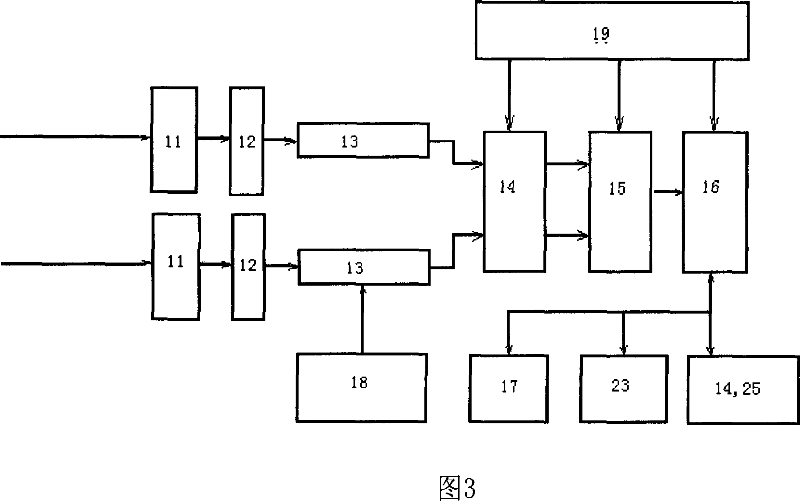

[0018] The host 2 of the light intensity meter of the present invention includes an optical fibe...

Embodiment 2

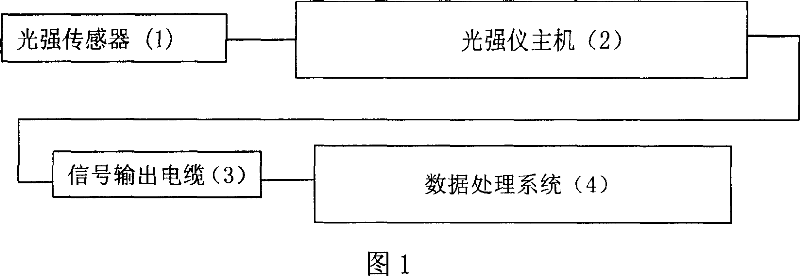

[0020] The application method of the light intensity signal measurement system in the heterogeneous photocatalytic reactor of the present invention is used in the measurement of the light intensity distribution and fluctuation signal in the multiphase photocatalytic reactor.

[0021] In the present invention, the tail joints of the light intensity sensor 1 are respectively connected to the optical fiber sensor interface 11 of the light intensity meter host 2 to connect and fix; the communication interface 17 of the light intensity meter host 2 is connected and fixed with the communication interface of the computer with the signal output cable 3, and the light is turned on. Strengthen the power supply of the instrument host 2, preheat for 20 to 30 minutes, and run the data analysis software. First insert the light intensity sensor 1 into the measuring hole of the heterogeneous photocatalytic reactor to adjust the sensitivity, first press the zero adjustment key on the light inte...

Embodiment 3

[0023] The application method of the light intensity signal measurement system in the heterogeneous photocatalytic reactor of the present invention is used in the absolute light intensity measurement in the heterogeneous photocatalytic reactor.

[0024] In the present invention, when the absolute light intensity signal needs to be measured, the light intensity signal measurement system is first calibrated, that is, the light intensity sensor 1 of the light intensity signal measurement system and the sensor of the ordinary light intensity measuring instrument are respectively facing the light source for measurement in the atmospheric environment Use parallel light to measure the light intensity at the same position, and obtain the average value of the two groups of measured light intensities by changing the brightness or distance of the light source and establish the corresponding relationship between the two groups of data. Then according to the method of Embodiment 2, the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com