Material feeding device

A technology of intermediate shells and metering discs, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as complex process equipment, and achieve convenient assembly and disassembly, simple maintenance and repair, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

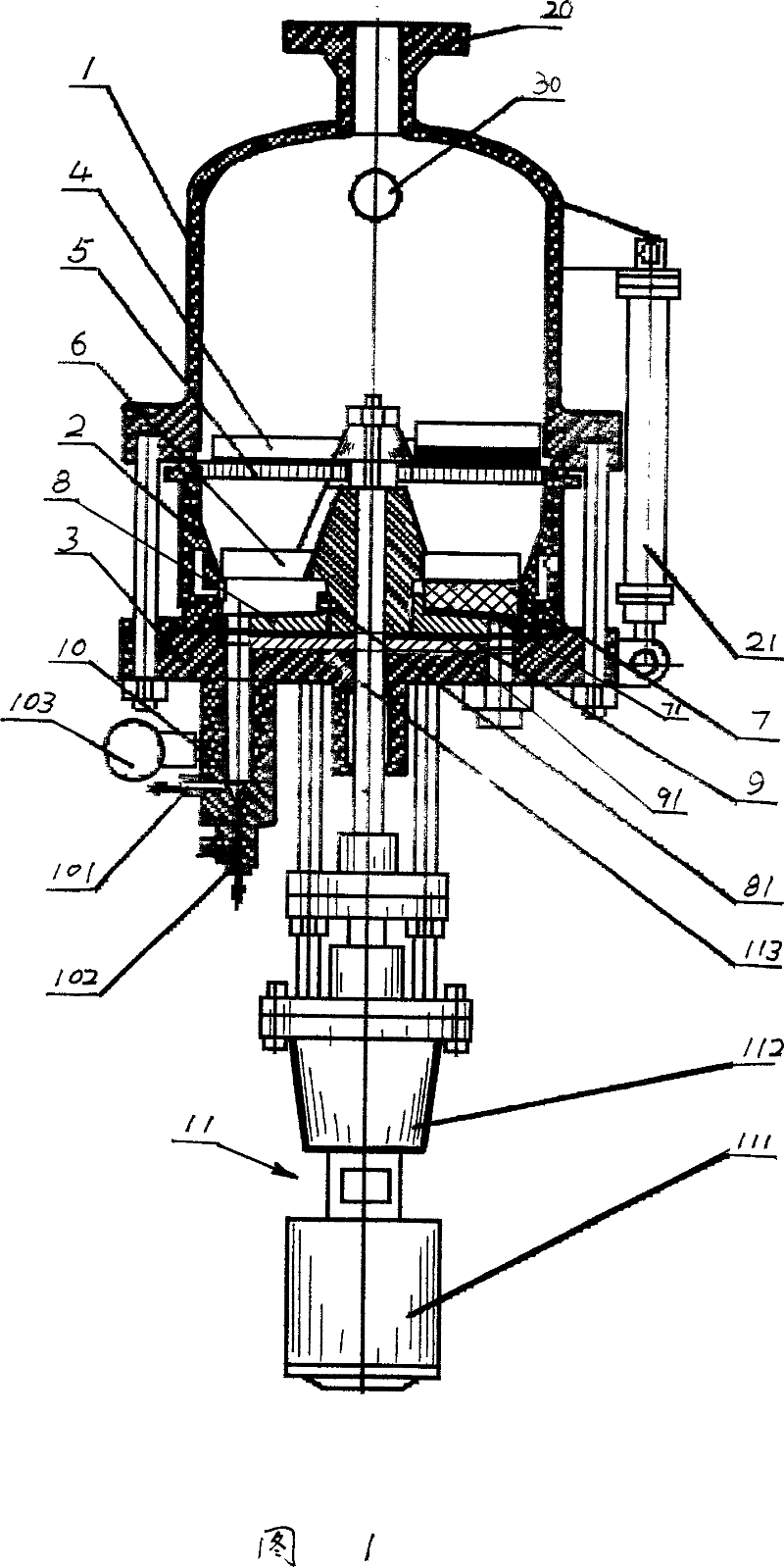

[0011] As shown in Figure 1, a batching device is mainly composed of a storage bin housing 1, an intermediate housing 2, a bottom flange 3, a rotating brush 4, a filter screen 5, an agitator 6, a floating disc assembly 7, and a rotating metering disc 8. The fixed plate 9 is composed of the carrying section assembly 10 and the power transmission part 11, wherein: the cylindrical storage bin shell 1 and the intermediate shell 2 are screwed together by the bottom flange 3 to make it a whole for storage and work. The upper part of the storage bin housing 1 is provided with a feeding port 20 and a discharge port 30, and a disassembly tool 21 is provided on the outside of the storage bin housing 1 and the intermediate housing 2, and the motor 111 and the reducer 112 in the power transmission part 11 It is connected with the transmission shaft 113, the end of the transmission shaft 113 is connected with the rotating brush 4, the middle part is connected with the agitator 6 and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com