Lumber and the processing method

A technology of solid wood and boards, applied in the field of wood processing, can solve the problems of low product utilization, low processing efficiency, uneven deformation of wood boards, etc., achieve uniform internal stress and deformation, improve production efficiency, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] The second embodiment of the structure of the solid wood plank in the length direction is:

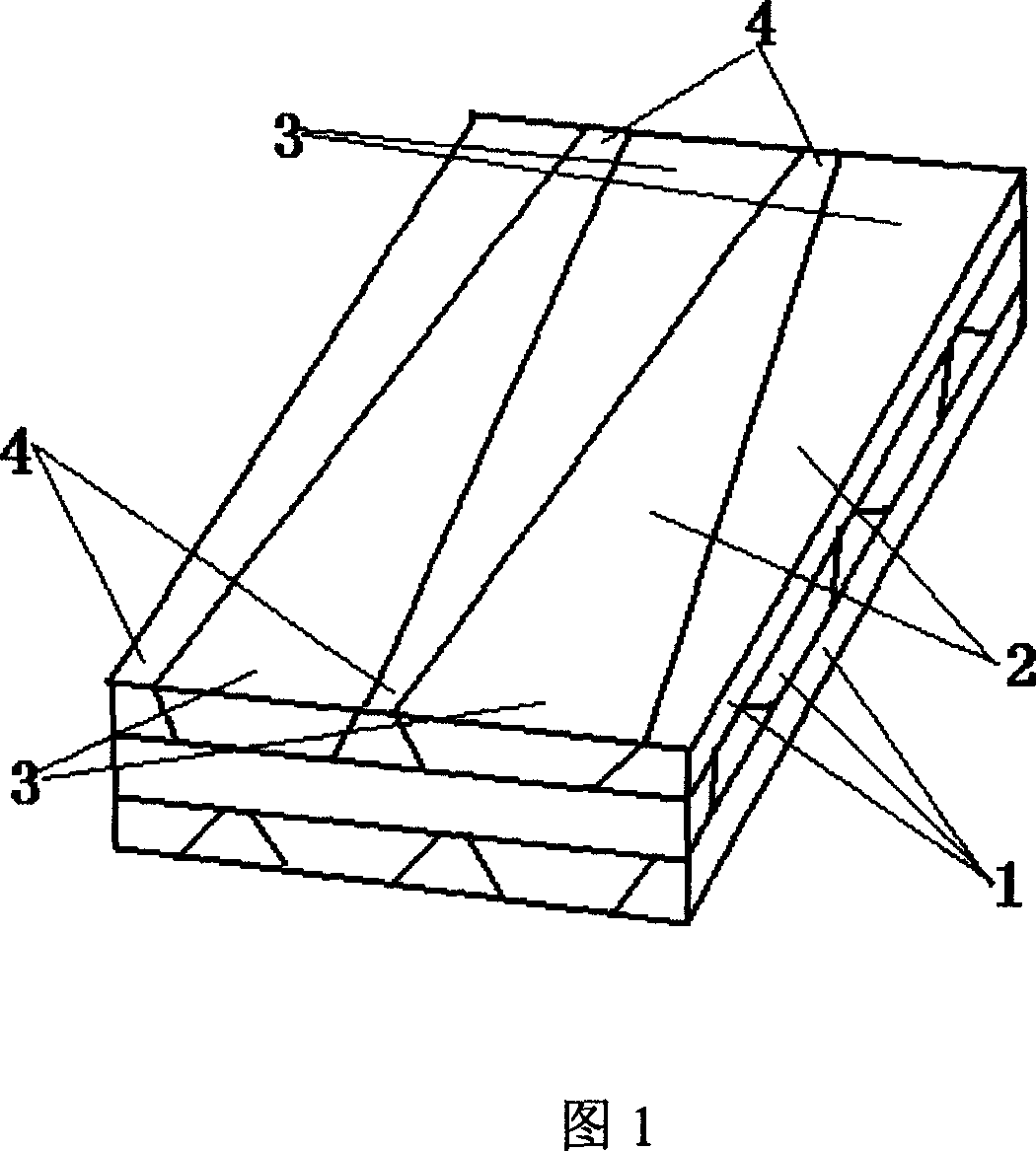

[0048] As shown in Figure 1, if the appearance requirements do not allow it to be spliced in the length direction, then the present embodiment proposes the following solution: the splicing plate 2 on the solid wood veneer panel 7 is a complete wooden block in the length direction , and all the splicing plates 2 on the two outer surfaces of the solid wood board are spliced without gaps, and the splicing plates 2 on the solid wood veneer core board 8 can be two or more wooden blocks in the length direction For splicing, the splicing seams in the length direction of the splicing plates 2 adjacent to the side are staggered from each other. If the solid wood veneer core board 8 has a little defect, it is allowed to have a small splicing gap, and it does not need to be excessively processed, and its appearance effect will not be affected. This embodiment can achieve the same effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com