Detecting method for position of photomask graphics

A detection method and photomask technology, which are applied to the photoengraving process of the pattern surface, the originals for photomechanical processing, the exposure device of the photoengraving process, etc., can solve the problem of high risk of time-consuming and undetected, Achieve the effect of improving detection efficiency and detection accuracy, saving economic costs and reducing detection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better illustrate the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

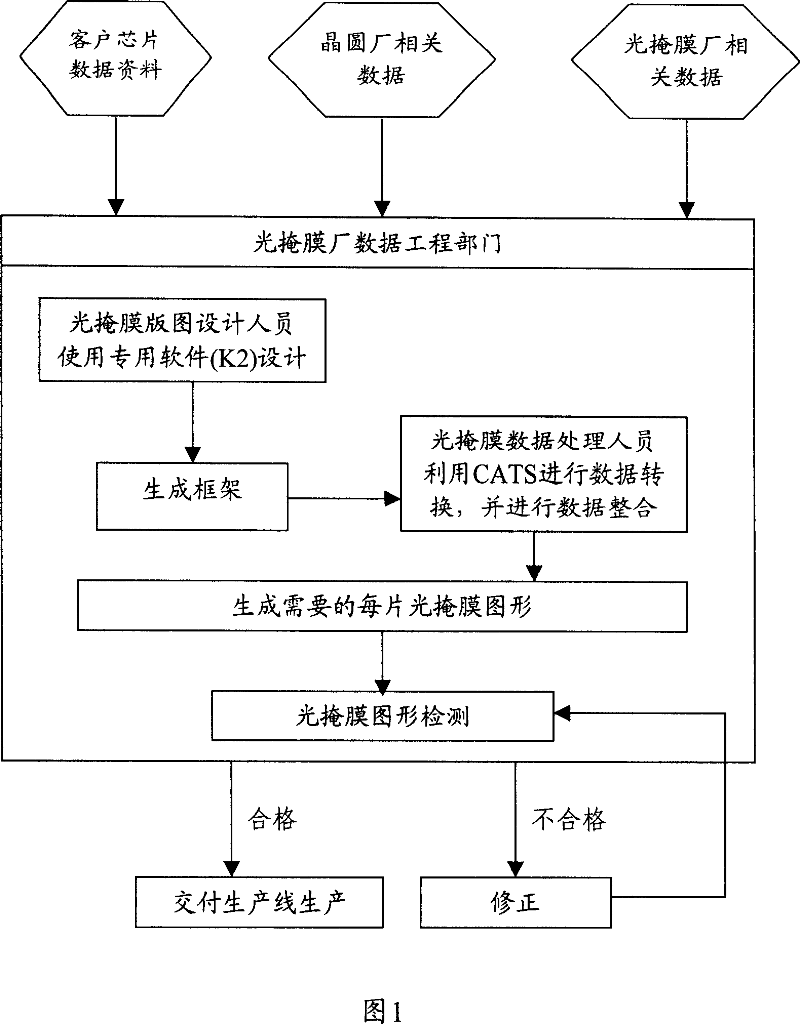

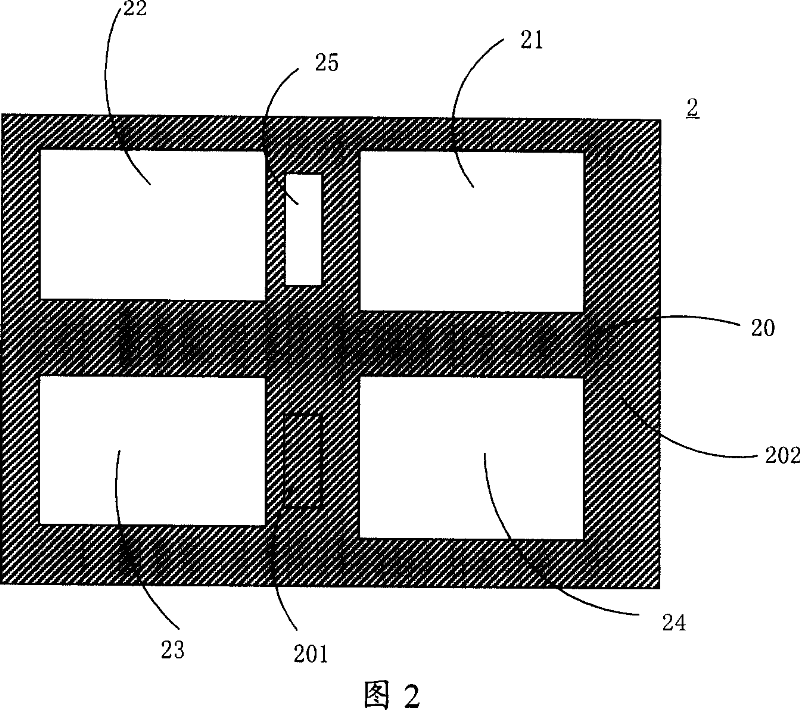

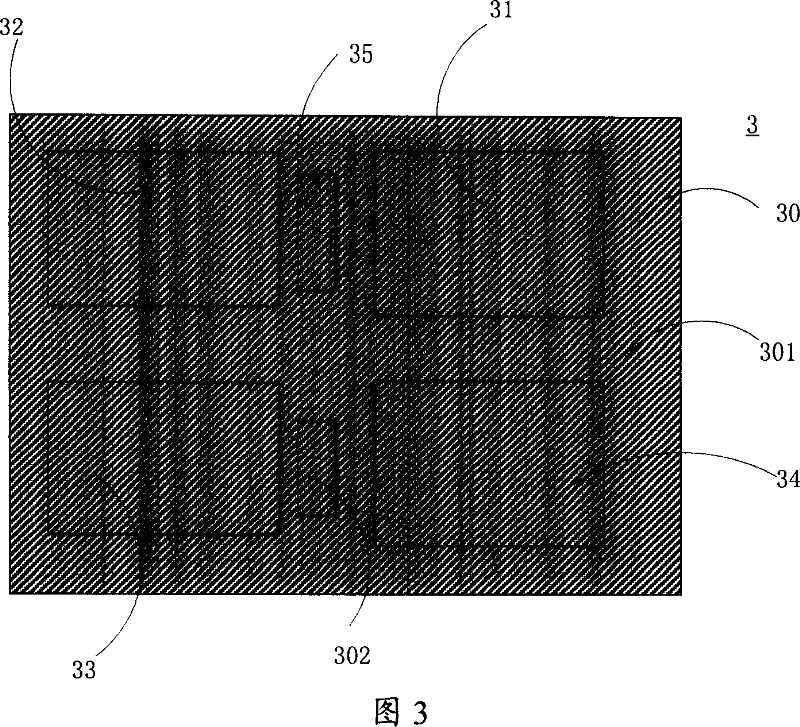

[0036] The invention makes full use of computer software and hardware resources and the photomask layout and photomask frame generated in the computer, and processes the graphics and data through the computer to achieve the purpose of automatic computer detection, so as to improve the detection efficiency and detection accuracy. The photomask pattern position detection of the present invention is mainly divided into the following two parts: the first part is to detect whether there is an overlap between the frame pattern on the photomask layout and the filling pattern; the second part is to detect the photomask layout Whether there are overlaps or gaps between the filled graphics and the filled graphics.

[0037] In the first part of the photomask pattern position detection, since the frame pattern of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com