Thin film forming apparatus and method thereof

A film and substrate technology, applied in the field of forming electrode films of piezoelectric elements, can solve the problems of shortened maintenance cycle, idle rollers, and many bolts, etc., and achieve the effect of improving utilization rate and improving handling parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

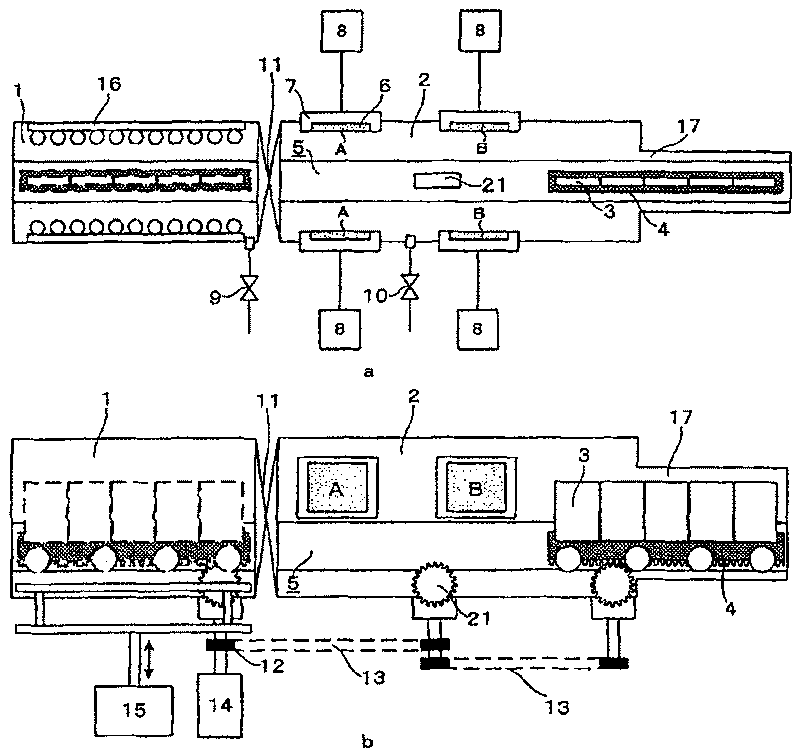

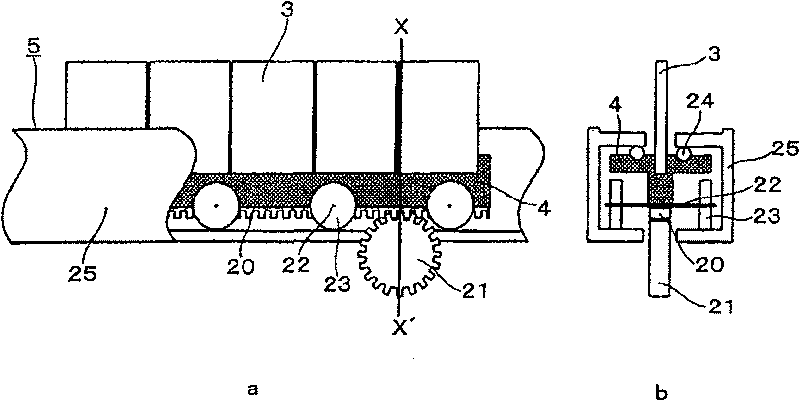

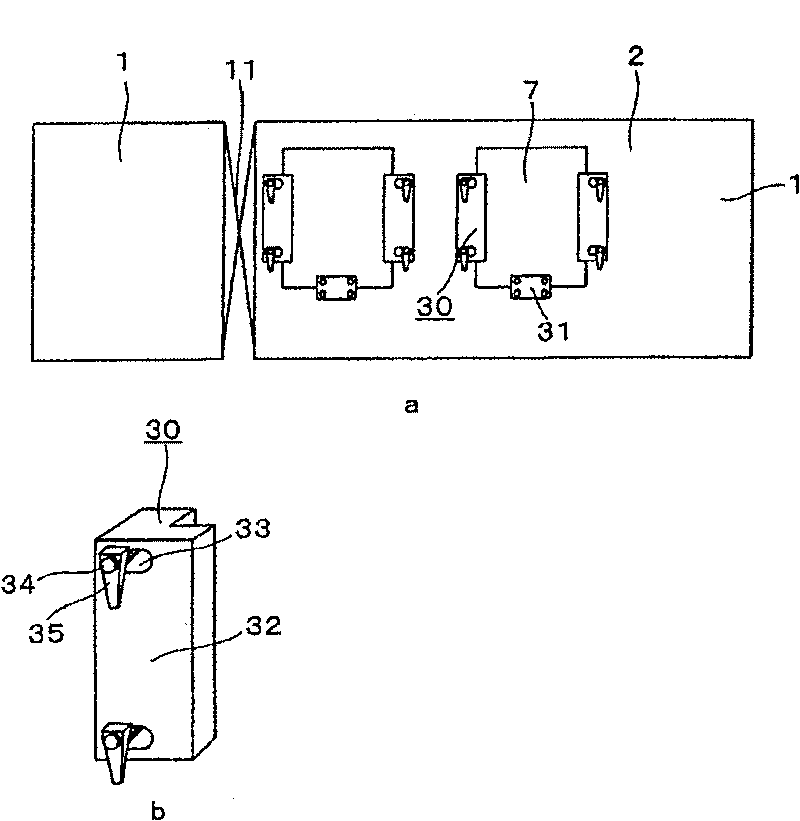

[0071] figure 1 An example of the electrode film forming apparatus of the present invention is shown, and the same parts as those in the prior art are given the same reference numerals and their descriptions are omitted. The device consists of a preparation and removal chamber 1 and a film formation chamber 2, figure 1 a is a schematic view of the interior of each chamber viewed from above. figure 1 b is a schematic view of the interior of each chamber viewed from the side. The embodiment omits the stocker for the purpose of improving productivity and reducing the area occupied by the device, and the stocker can also be provided as required.

[0072] The preparation taking out chamber 1 and the film forming chamber 2 are separated by a gate valve 11 , the film forming chamber 2 is connected with a main valve 10 , and the preparation taking out chamber 1 is connected with a roughing valve 9 . The main valve 10 is connected to the main pump not shown, and the roughing valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com