Ink control apparatus, printer, and printing method

A control device and ink technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of complicated operations, inability to eliminate the workload of operators, and inability to eliminate the complexity of color adjustment operations, so as to simplify operations, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

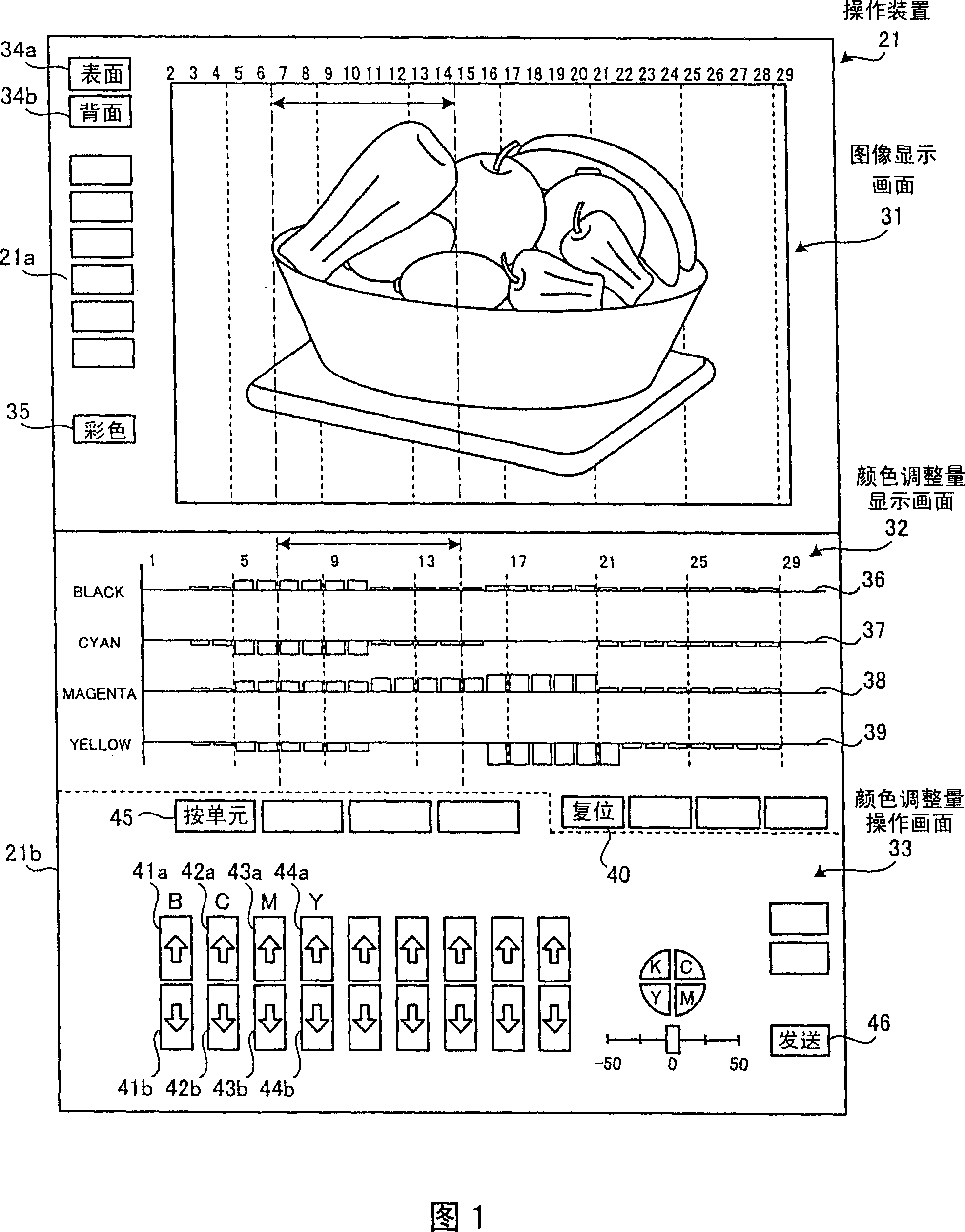

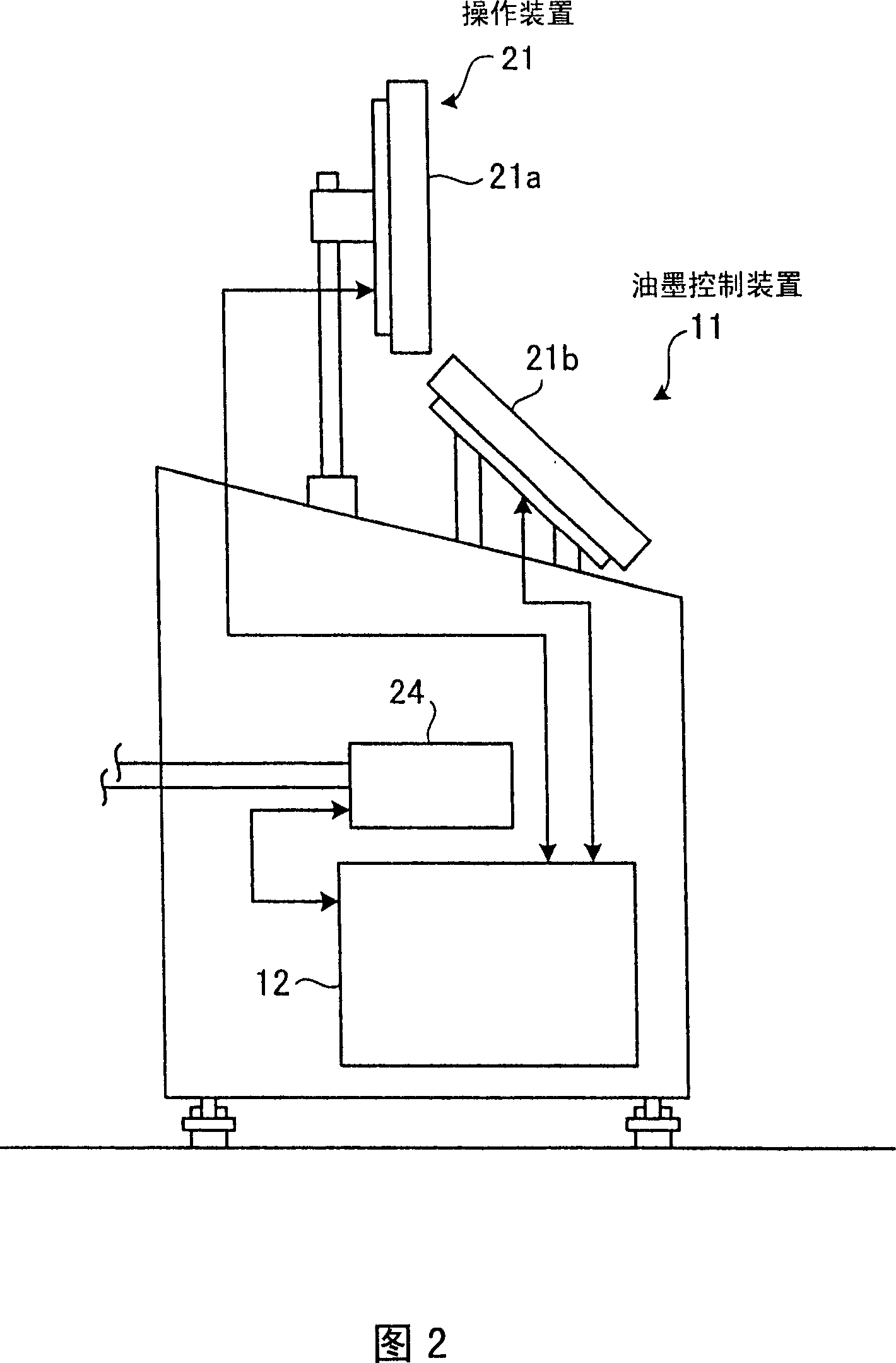

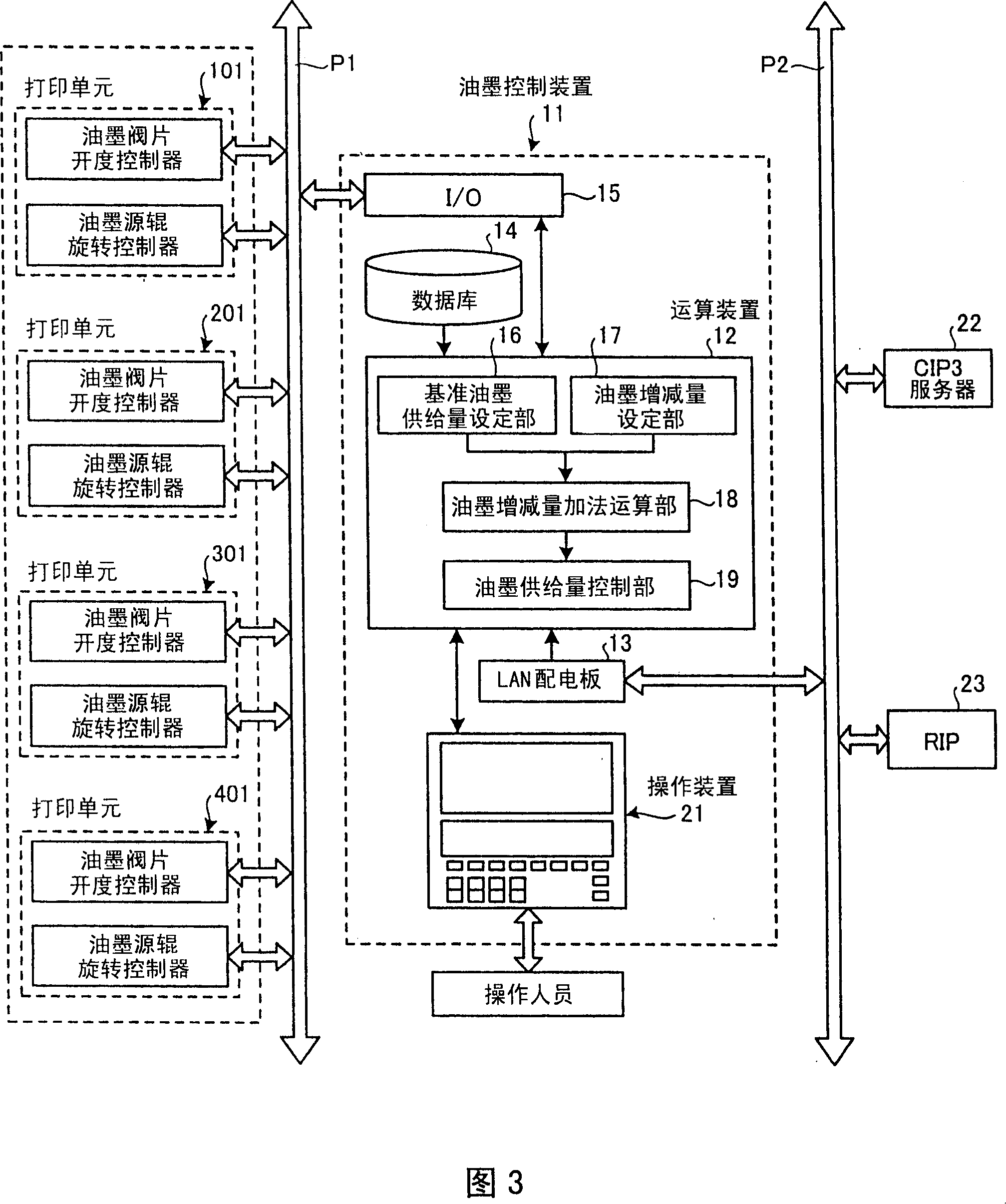

[0060] 1 is a schematic diagram showing an operating device of an ink control device in a printer according to Embodiment 1 of the present invention, FIG. 2 is an external view of the ink control device in the printer of Embodiment 1, and FIG. 3 is a printer of Embodiment 1. The schematic configuration diagram of the ink control device in Fig. 4 is a processing block diagram of the ink supply amount control of each ink valve plate range of the ink control device in the printer of embodiment 1, and Fig. 5 is a diagram showing that the opening degree of the ink valve plate is changed relative to 6 and 7 are schematic diagrams showing the overall adjustment method of the density change amount, FIG. 8 is a flow chart of the ink supply amount control of the ink control device in the printer of Embodiment 1, and FIG. 9 is a graph of the scanning line rate. A schematic configuration diagram of a planographic printing printer to which the printer of Example 1 is applied.

[0061]In th...

Embodiment 2

[0094] 10 is a schematic diagram showing the operating device of the ink control device in the printer according to Embodiment 2 of the present invention, FIG. 11 is a schematic configuration diagram of the ink control device in the printer of Embodiment 2, and FIG. This is a flow chart of the ink supply volume control of the ink control device in the printer. In addition, the overall configuration of the planographic printing printer of this embodiment is substantially the same as that of the first embodiment described above, and will be described with reference to FIGS. and omit repeated descriptions.

[0095]In the planographic printing printer having the ink control device of Embodiment 2, as shown in FIG. It has: an image display screen 31 that divides a print pattern image based on PPF data into ink valve ranges and displays it; a color adjustment amount display screen 32 that displays a set color adjustment amount for each ink valve range; Color adjustment amount oper...

Embodiment 3

[0138] 13 is a schematic diagram showing the operation device of the ink control device in the printer according to the third embodiment of the present invention, and FIG. 14 is a flow chart of ink supply amount control by the ink control device in the printer according to the third embodiment. In addition, the overall configuration of the planographic printing printer of this embodiment is substantially the same as that of the first embodiment described above, and will be described with reference to FIGS. and omit repeated descriptions.

[0139] In the lithographic printing printer having the ink control device of the third embodiment, as shown in FIG. 13 , the operating device 81 for operating the lithographic printing printer of the present embodiment is a touch panel type display operable by touching the screen with fingertips, It has: an image display screen 31 that divides a print pattern image based on PPF data into ink valve ranges and displays it; a color adjustment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com