Biophotosynthetic reactor apparatus and process for producing micro algae

A photosynthetic reactor and microalgae technology, applied in photobioreactors, stress-stimulated microbial growth methods, biochemical equipment and methods, etc., can solve problems such as inability to carry out all-weather annual production, uncontrollable production factors, and difficulties in intensive management , to achieve the effect of promoting photosynthesis, improving photosynthetic efficiency and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

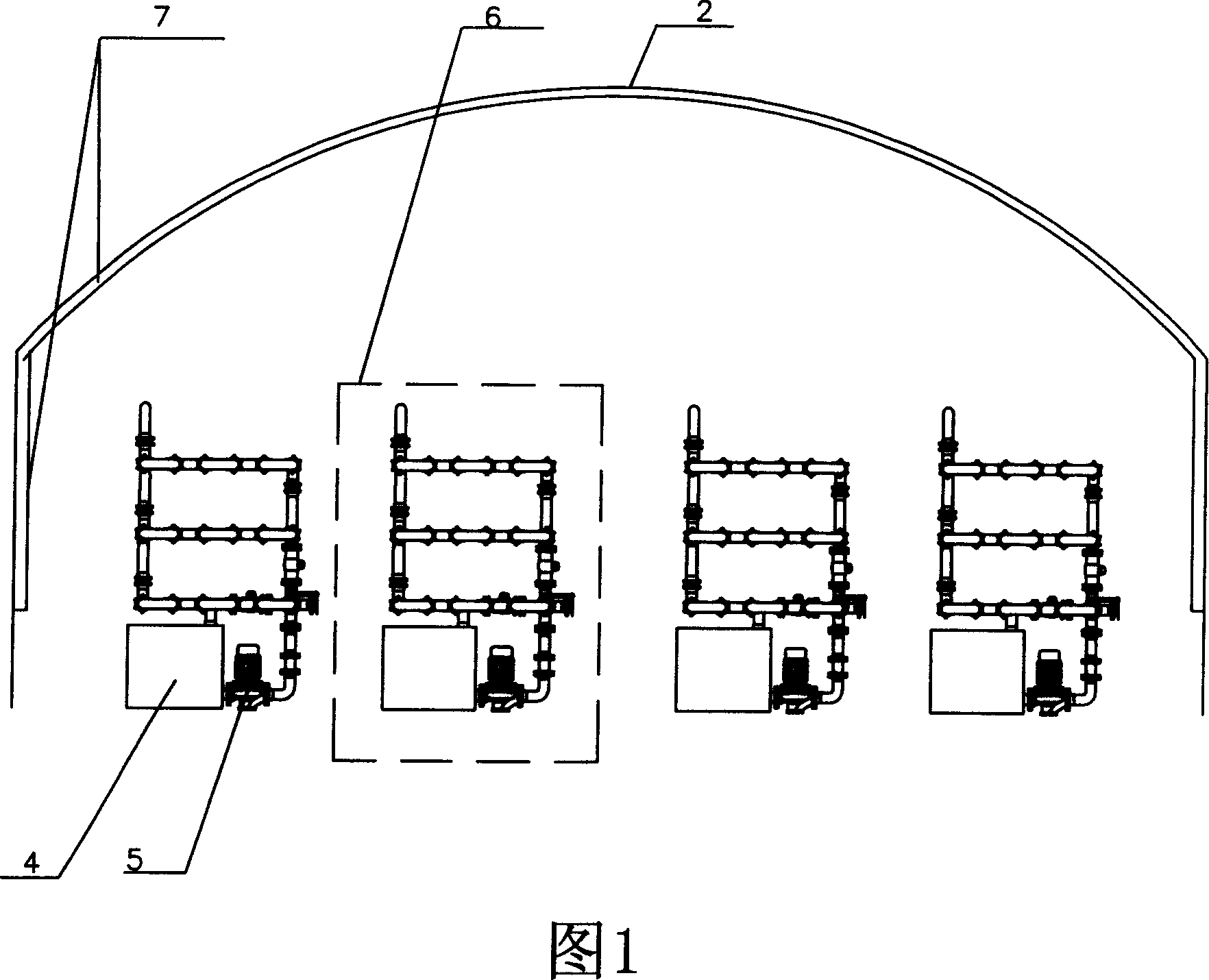

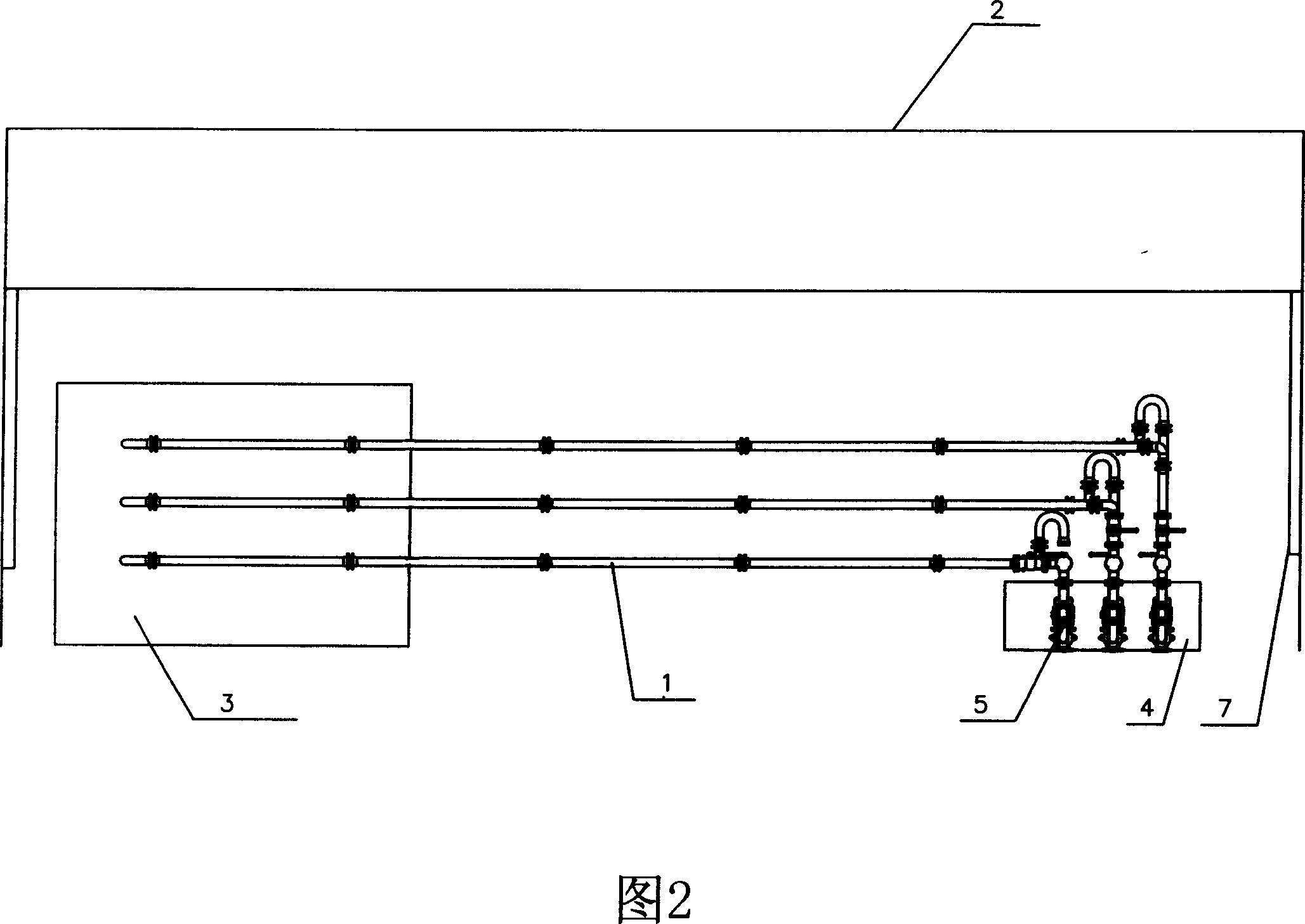

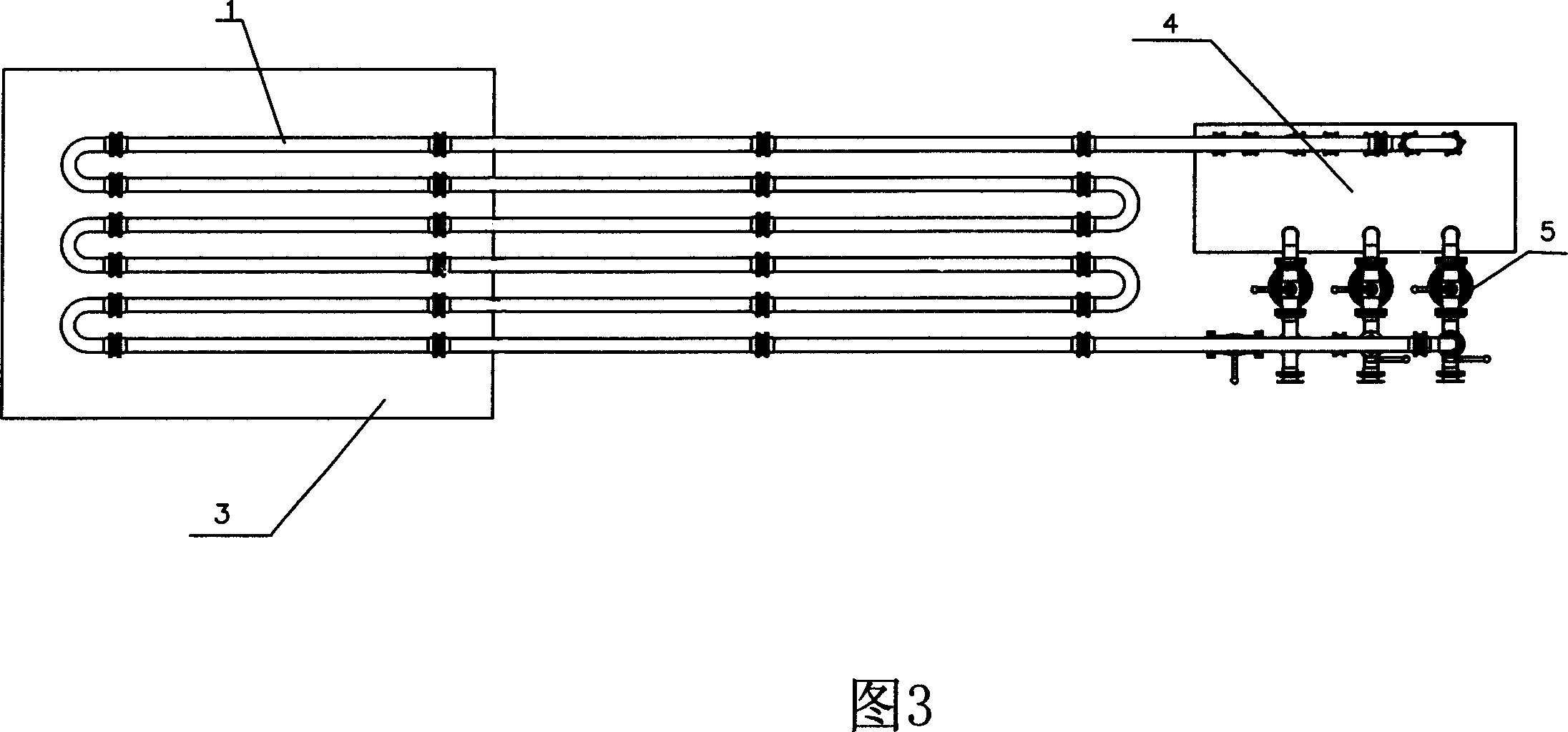

[0033] In the device for producing microalgae by a biological photosynthetic reactor of the present invention, the transparent photosynthetic greenhouse 2 is a light-converting film made of transparent rare-earth light-converting polypropylene, and the photosynthetic greenhouse 2 directly faces the sun to form a high-energy-gathering photoreceptor. Four closed circulation pipeline units 6 are installed in the photosynthetic greenhouse 2, and each closed circulation pipeline unit 6 includes three layers of closed circulation pipelines that are parallel to each other and individually circulated. The tubes and straight tubes are connected by U-shaped borosilicate glass pipelines, which communicate with each other. The inlet pump 5 is installed at the inlet of the pipeline, and is connected with the water source, the carbon dioxide source and the microalgae suspension tank 4, and the pipeline outlet is connected with the microalgae suspension tank 4. The microalgae suspension tank ...

Embodiment 2

[0041] The same as the device for producing microalgae in the biological photosynthetic reactor described in Example 1, the closed circulation pipeline is made of transparent polypropylene (PVC).

Embodiment 3

[0043] A process for producing chlorella using the bio-photosynthetic reactor described in Example 1 or 2 for producing microalgae, stocking chlorella in a closed circulation pipeline in a transparent photosynthetic greenhouse, and feeding the closed circulation pipeline 1 through an inlet pump 5 Add 6 tons of water (average 1.5 tons per circulation unit) and chlorella species to form a microalgae suspension, close the water source, pass carbon dioxide into the pipeline through the inlet pump 5, and control the chlorella in the closed circulation pipeline through the pump The suspension is in a turbulent state with a velocity of 1m / s. The chlorella suspension carries out photosynthesis in the closed circulation pipeline, grows and reproduces, and is controlled by the inlet pump 5, circulates between the closed circulation pipeline and the microalgae suspension tank, and passes through the temperature of the circulating water tank 3 and the photosynthetic greenhouse 2. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com