Molten iron desulfurizing and demagging agent spraying gun

A technology of molten iron desulfurization and magnesium agent, which is applied in the direction of injection devices and liquid injection devices, can solve problems such as channel blockage, achieve the effects of reducing load, reducing infrastructure investment and operating costs, and simplifying maintenance processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

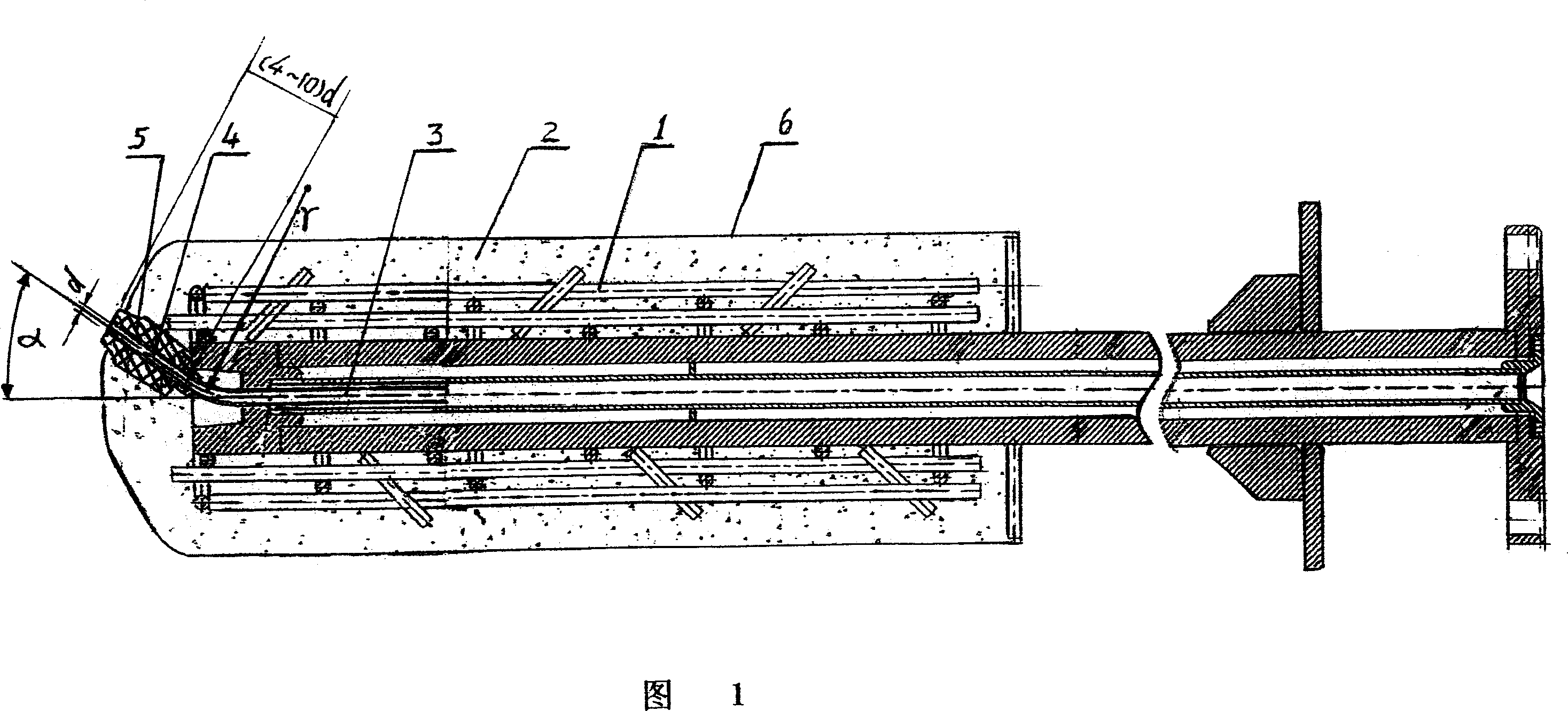

[0026] A section of passage at the outlet of the spray gun of the present invention is made into a replaceable nozzle form, and is connected with a curved main passage in a threaded manner. The bending angle of the main passage to the longitudinal axis of the spray gun is 40°, and the bending radius is 110mm. The replaceable nozzle is made of refractory heat-strength material (such as titanium alloy), and the nozzle is equipped with a replaceable sleeve, which is made of refractory material (such as graphite) that is not infiltrated by molten iron. At the same time, the casing The length is 8 times the length of the inner diameter of the channel.

[0027] As shown in Figure 1, the molten iron desulfurization magnesium agent spray gun of the present invention comprises: a gun body 6, a skeleton 1, a refractory lining 2 arranged outside the skeleton 1, a passage 3 matched with the skeleton 1; the outlet of the passage 3 Adopt curved structure. The outlet of the channel 3 is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com