Device and method for monitoring guiding thread in knitting machine

A technology for knitting machines and yarn guides, which is applied to measuring devices, knitting, textiles and paper making, etc., can solve the problems of high cost, time-consuming maintenance work, difficulty in manufacturing yarn breakage detectors, etc., and achieve the effect of increasing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

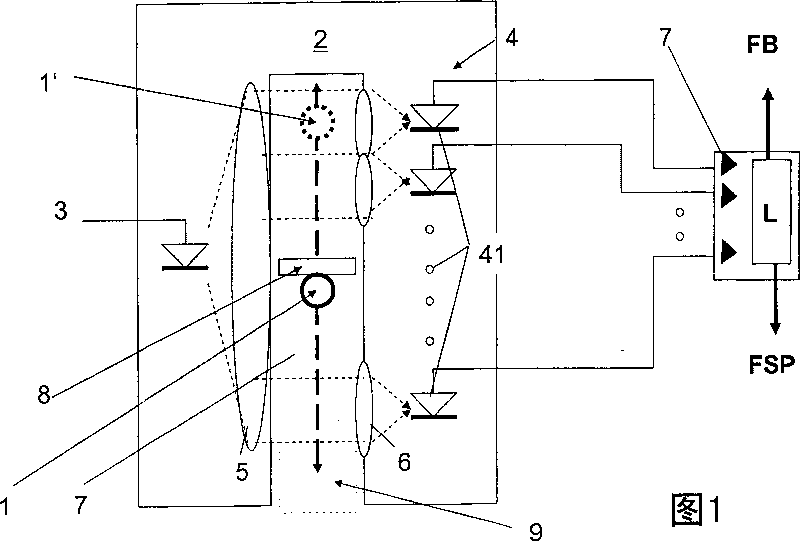

[0024] exist figure 1 A schematic diagram of the principle of a yarn sensor for monitoring the running of yarn in a knitting machine is shown in , which describes a cross-sectional view perpendicular to the extension line of the yarn passing through the device. It is assumed here that the yarn 1 is moved through a yarn feed direction which is oriented perpendicular to the drawing plane. The frame of the U-shaped structure shown around the position of the yarn 1 very schematically describes the optical sensor unit, which is formed in the form of a pair of fork-shaped optoelectronic devices. The fork-shaped optoelectronic device pair 2 has a light source 3 along one of its U-legs, which is configured in the form of a single-LED, a photodiode row or in the form of another light source of linear radiation and it on the other hand along its The further U-leg of the U-leg is provided with a photodetector arrangement 4 which, in the exemplary embodiment shown, consists of a combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com