Mudstone density measuring process

A technology for density determination and mudstone, which is used in material analysis by measuring buoyancy, special data processing applications, instruments, etc. It can solve the problems of complicated operation, large volume of instruments, and large amount of pure water, and achieve accurate measurement and large measurement container. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

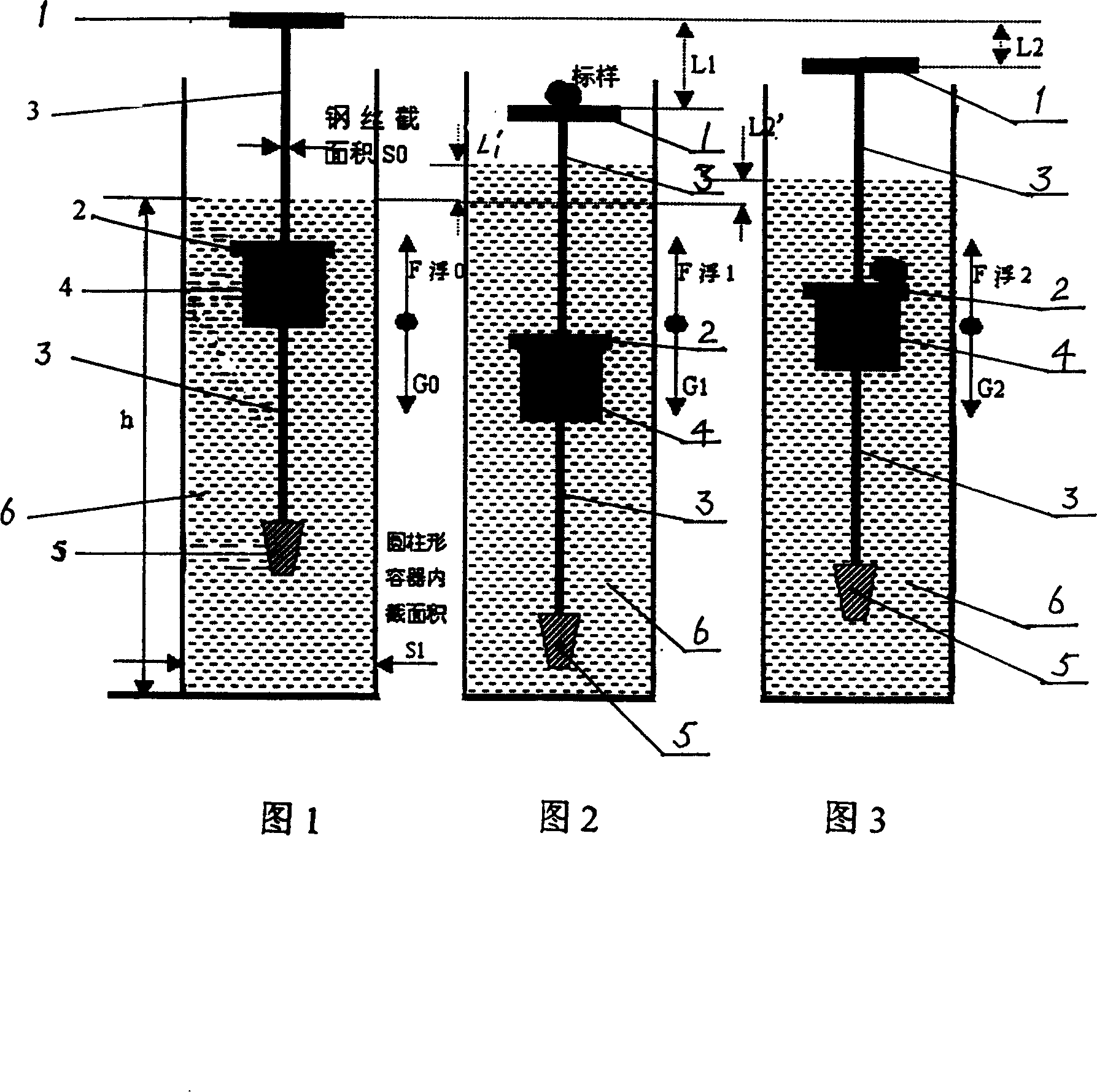

Method used

Image

Examples

Embodiment

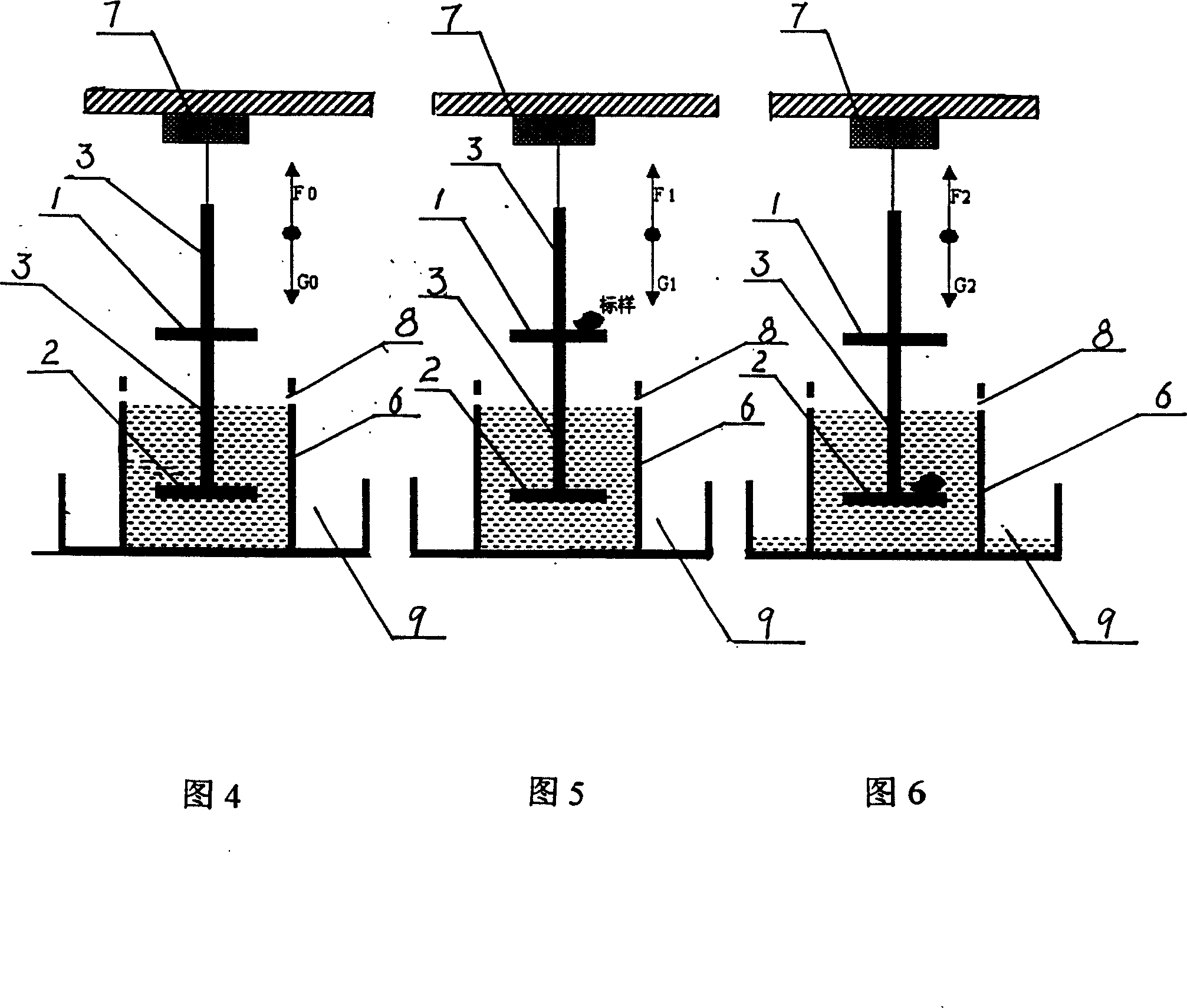

[0058] As shown in Figure 4, it is a structural schematic diagram of a mudstone density measuring instrument. The mudstone density measuring instrument is composed of an upper wall 1, a lower wall 2, a steel wire 3, a container 6, and a tension sensing device 7. The steel wire 3 is vertically connected up and down with each other. The upper wall 1 and the lower wall 2 are parallel, the upper wall 1 is arranged on the upper end of the container 6, exposed in the air, the lower wall 2 is immersed in the pure water in the container 6, and the top of the steel wire 3 is provided with a tension sensing device 7, The wall of the container 6 is provided with a self-overflow 8, and the container 6 is installed in the container 9. The container 6 has a self-overflow 8 in order to maintain the liquid level of pure water. Load cell, preamplifier, signal processing and tension display module. The main component is a high-precision tension sensor. The biggest feature of this sensor is that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com