One cycle PFC boost converter IC with inrush limiting, fan control and housekeeping supply control

A boost converter, single-cycle control technology, applied in high-efficiency power electronic conversion, control/regulation systems, instruments, etc., can solve the problems of high discrete components, complex design, difficulties, etc., and achieve the effect of eliminating the need

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

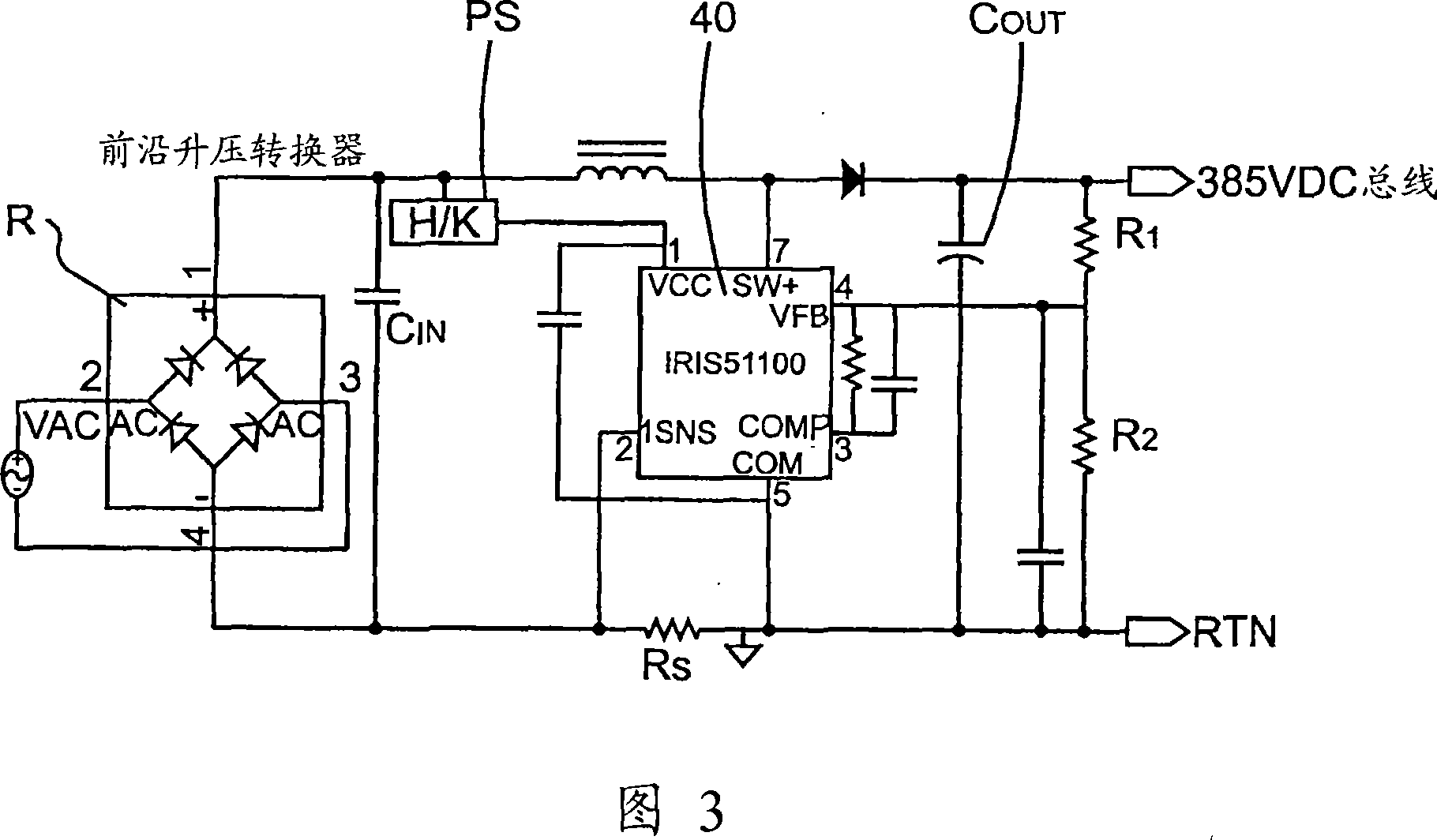

[0043] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

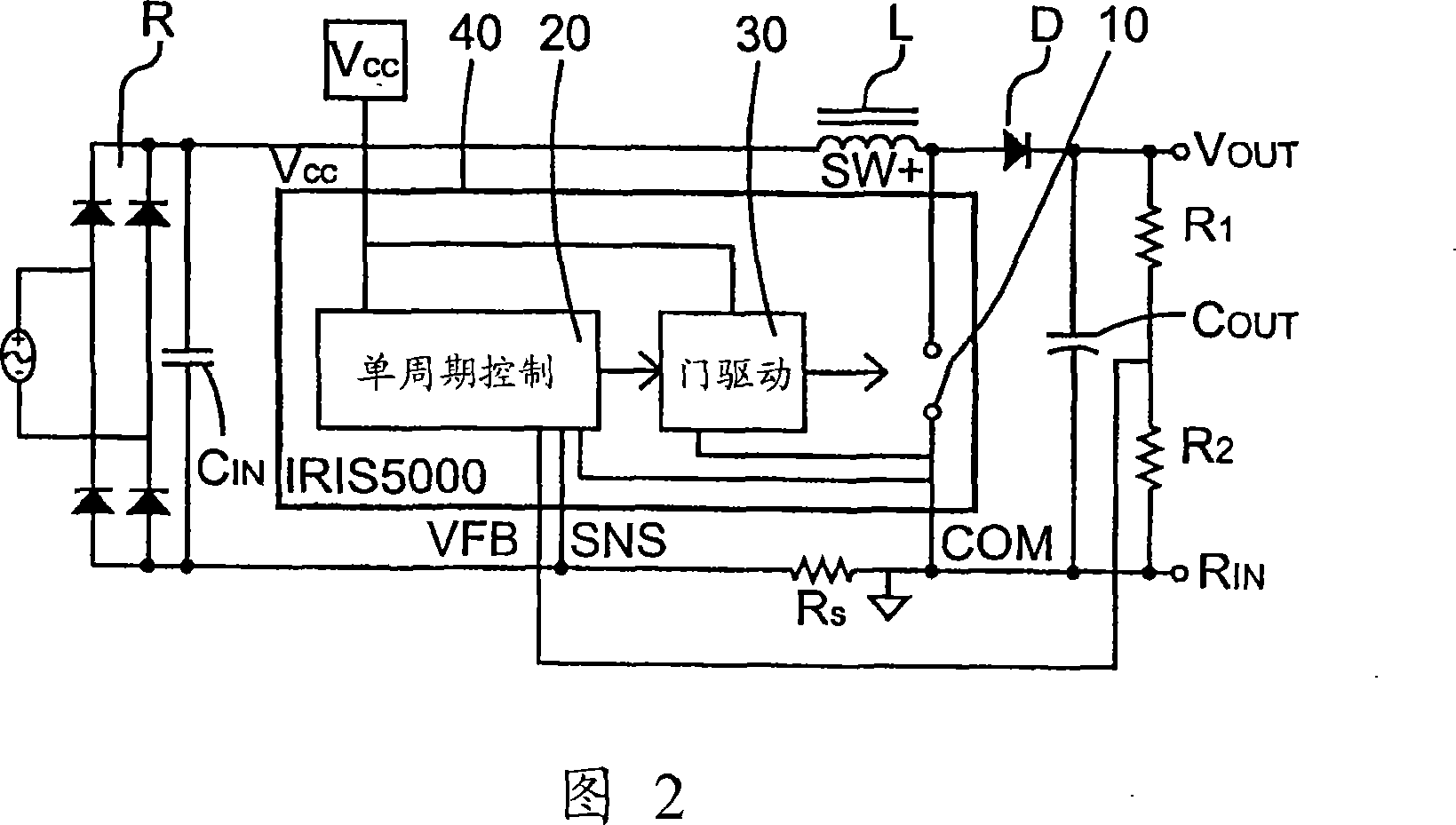

[0044] Figure 2 depicts a system-level block diagram representation of an OCC-based active power factor correction technique operating under a fixed-frequency, continuous conduction-mode boost converter topology. In CCM, the current in the inductor L is never allowed to go to zero. In the circuit of Fig. 2, the power switch 10, the PFC control circuit 20 based on OCC and the built-in (onboard) power switch driving circuit 30 are integrated into a single package 40, and the package 40 can dissipate the appropriate heat from the device to radiator (heatsink). Various power packages can be realized with this technique because the use of OCC technique reduces the number of pins required to implement a full CCM PFC boost converter.

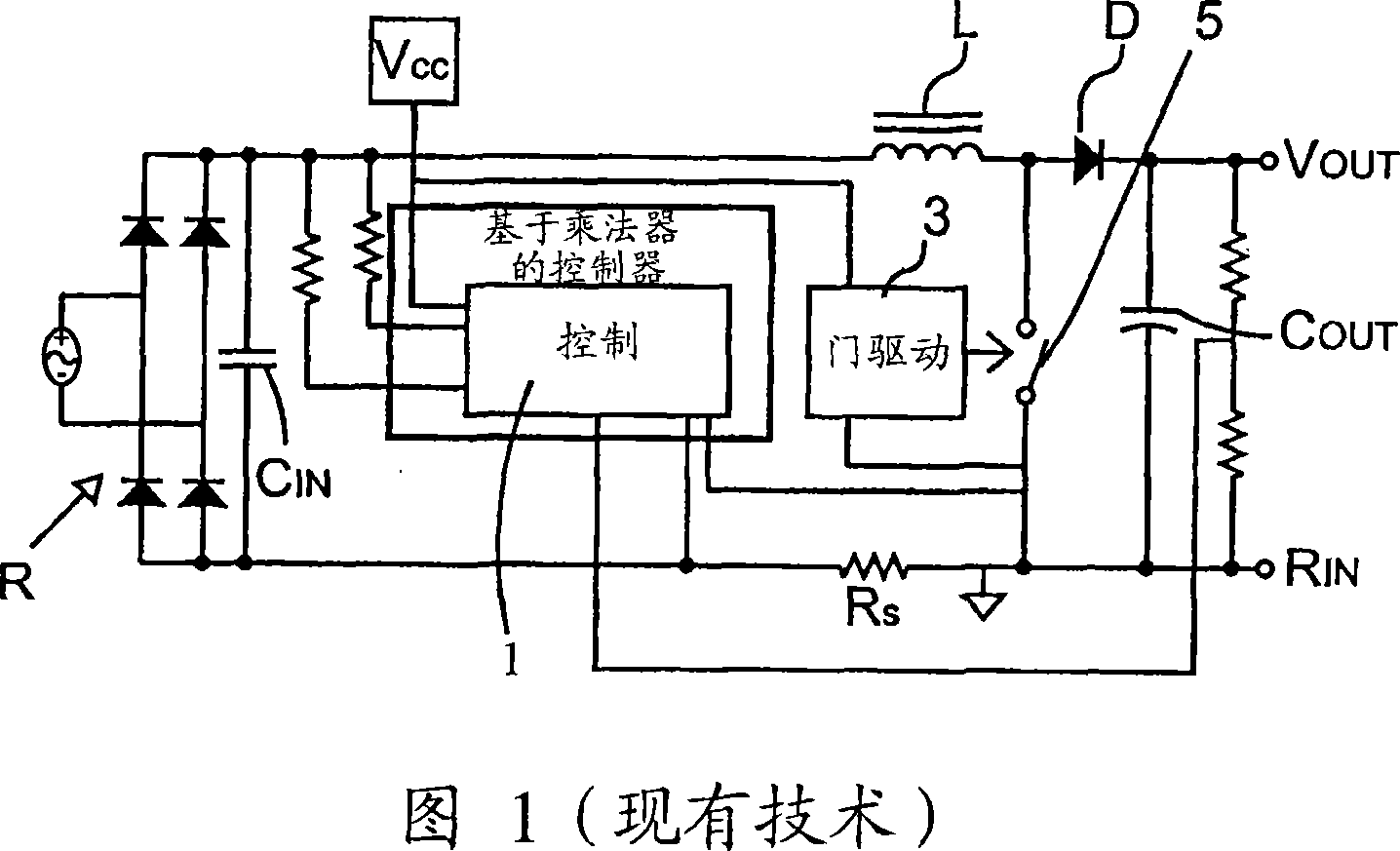

[0045] The control circuit 20 is based on the OCC method in which the multipliers and input voltage sensing described with reference to the prior art circuit in FIG. 1 are not required. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com