Method and equipment for machining bent pipe with small R

A processing device and pipe bending technology, applied in the field of mechanical processing, to achieve the effect of feasible method, obvious technological advancement and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

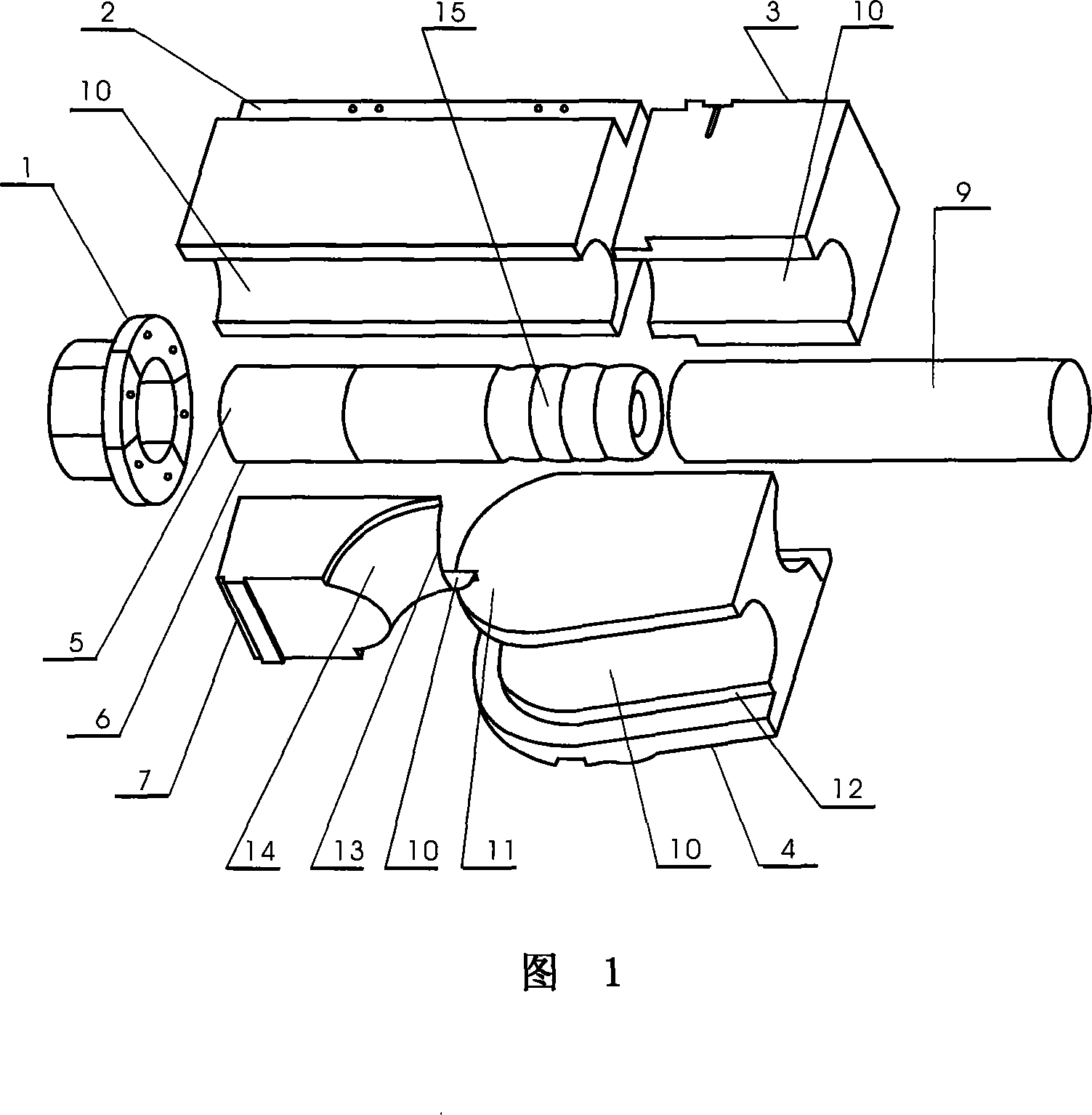

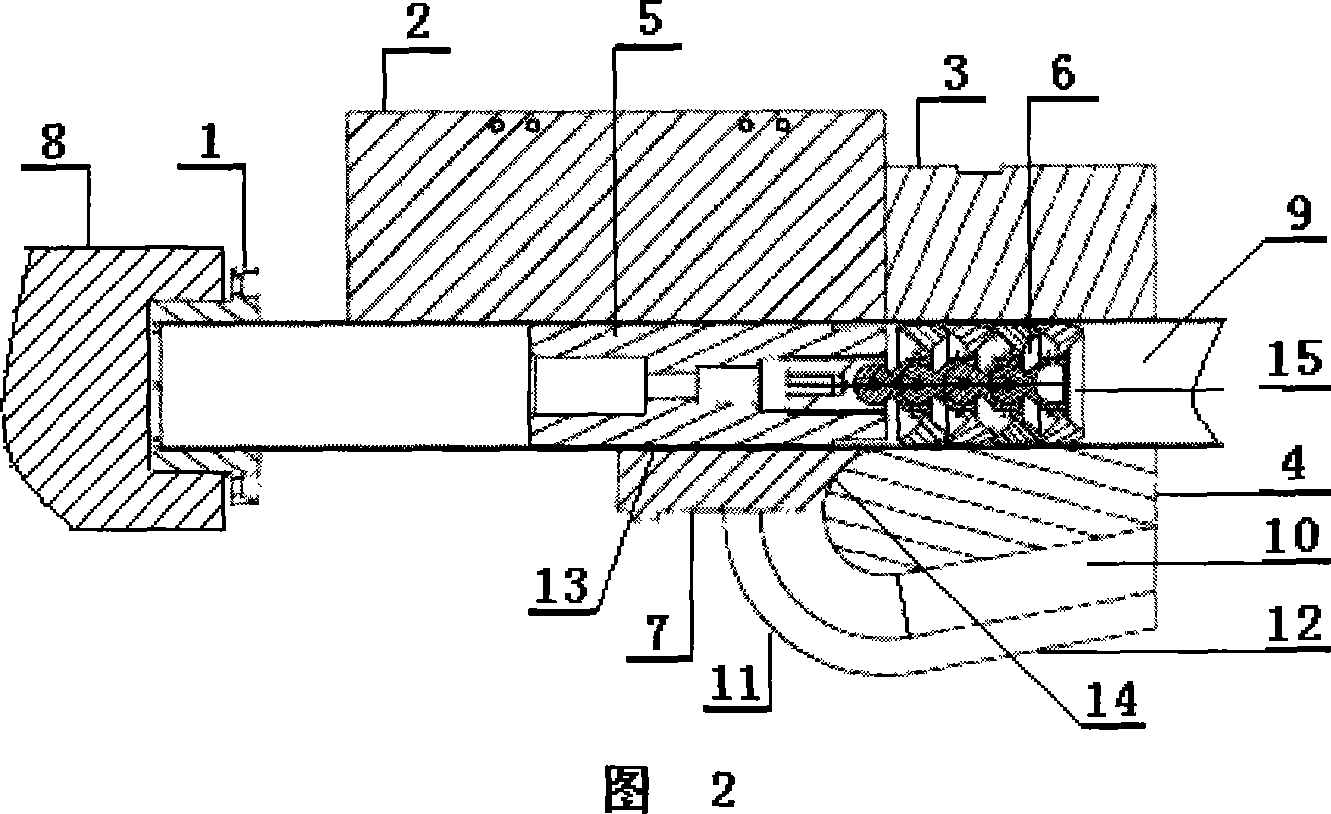

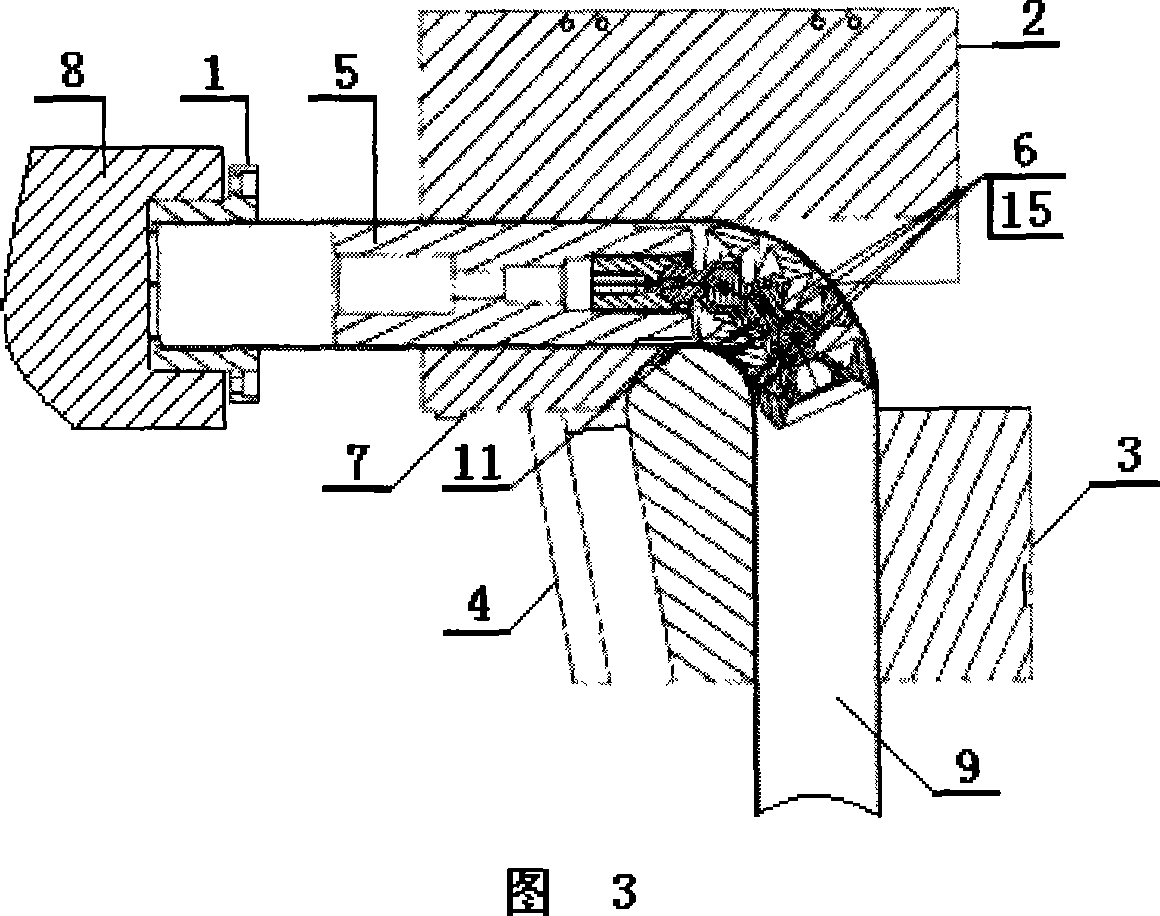

[0032]In Fig. 1, Fig. 2 and Fig. 3, the processing device of the small R bend pipe of the present invention mainly includes a three-dimensional numerical control pipe bending machine with hydraulic and servo motor drive mechanism, a forming bending mold and accessories, and a forming bending mold It contains an eight-jaw clamping mold 1, a master mold 2, a clamping mold 3, and a diameter mold 4. The auxiliary parts mainly include an active joint 6 with a core rod 5, an anti-wrinkle mold 7 and a push trolley 8. Wherein: the diameter die 4 is R-shaped, and the continuous edge formed by the edge of the convex semicircular R-shaped curved front end portion 11 and the edges of the inclined portions 12 on both sides is provided with a side surface corresponding to the outer diameter of the workpiece 9 The semi-circular arc noodle-shaped limiting groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com