Tower type dual-purpose machine for lifting and raw material disposal

A tower-type lifting and distributing technology, which is applied in cranes, building materials processing, construction, etc., can solve problems such as unsafe, automatic distributing, and increased lifting weight, etc., and achieves the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

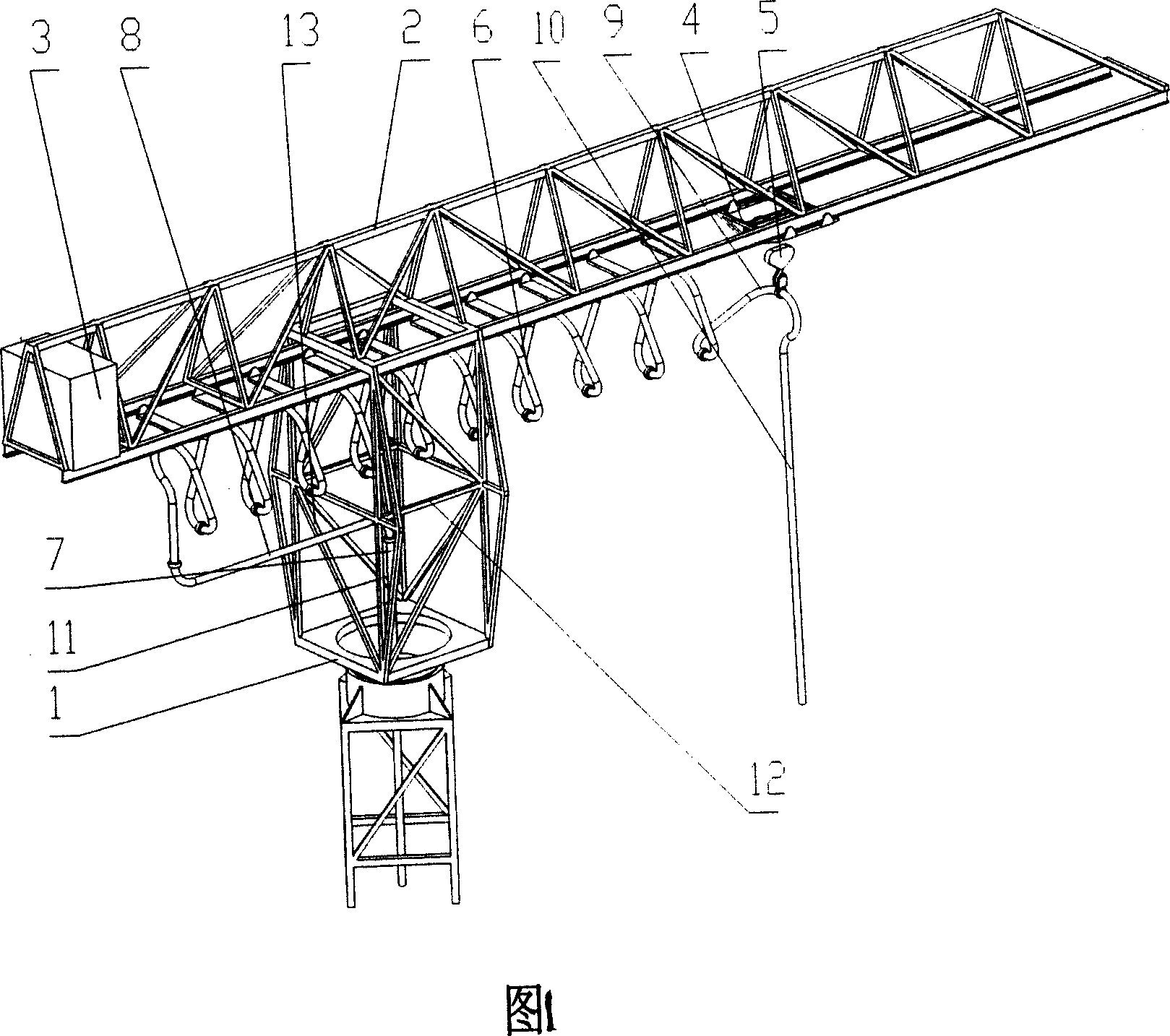

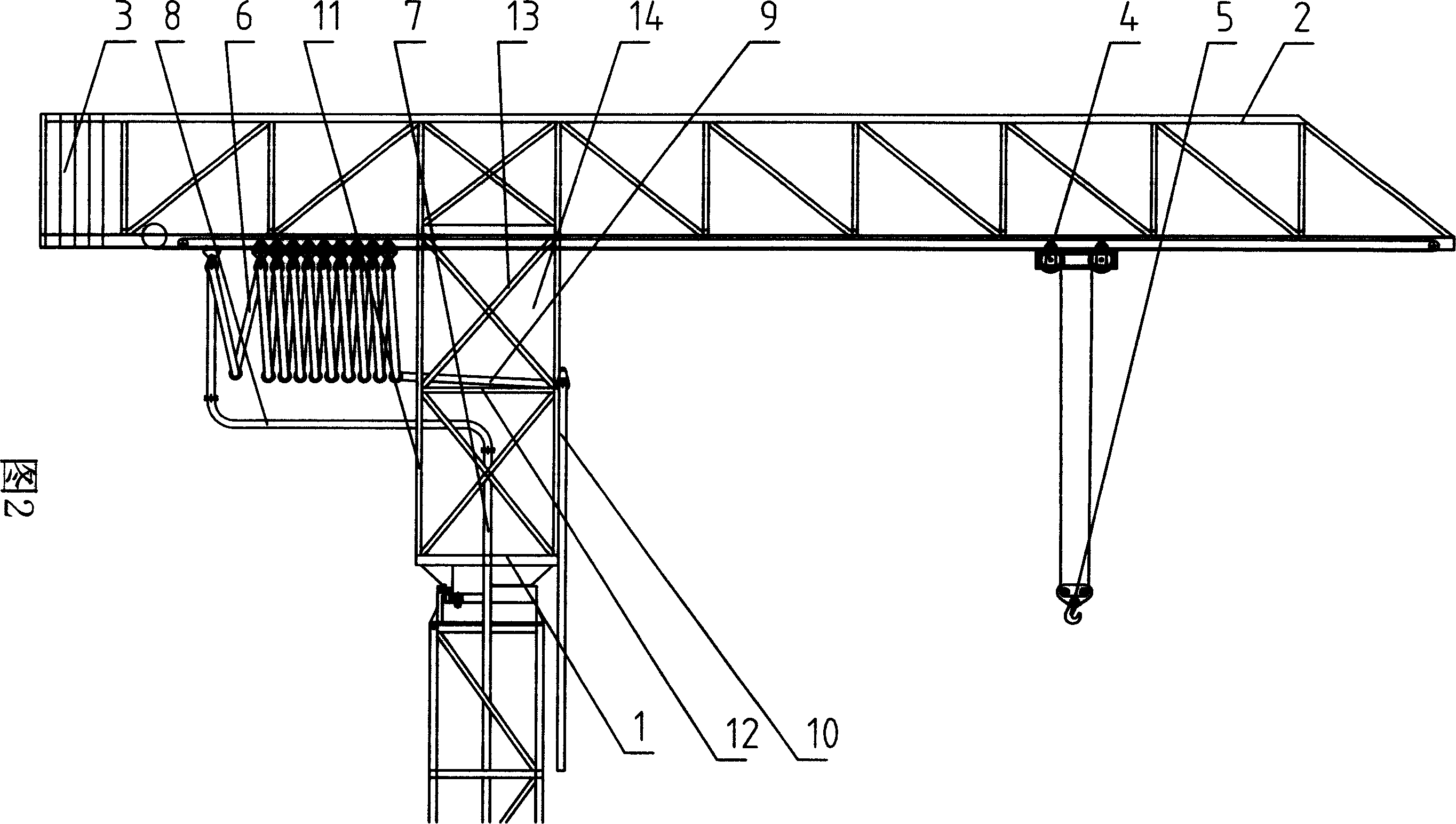

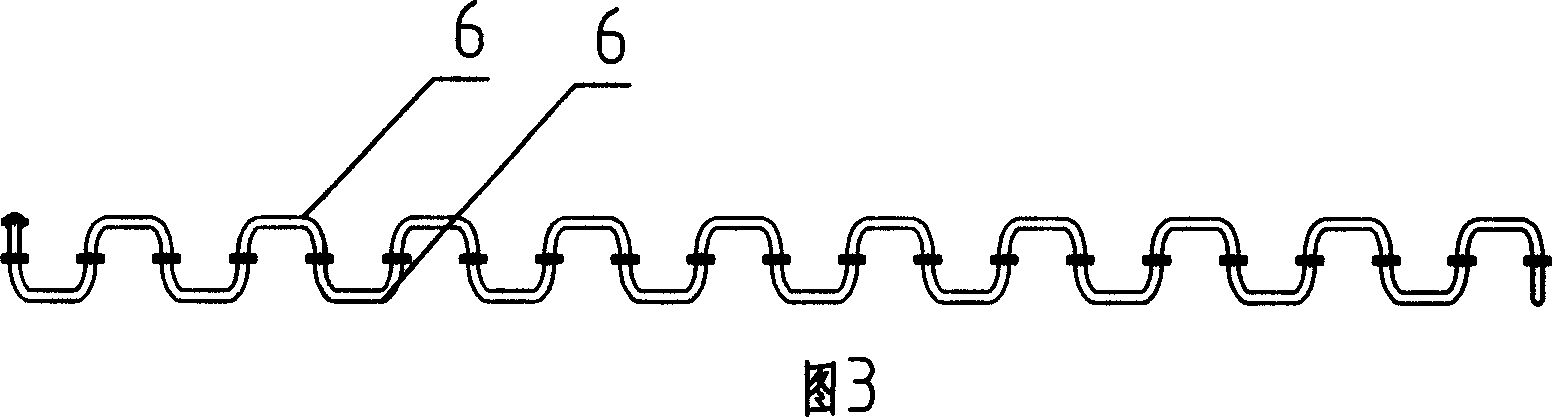

[0018] As shown in Figures 1 to 4, the tower-type lifting and distributing dual-purpose machine includes a slewing tower body 1, a boom 2 installed on the slewing tower body 1, a counterweight 3 installed on the boom 2 and a pulley 4. Concrete pump (not shown), concrete conveying pipe, hook 5 is provided on the tackle 4, the concrete conveying pipe includes the first curved pipe 6, the long straight pipe 7 installed in the tower body, connected with the long straight pipe 7 The second curved pipe 8 and the second curved pipe 8 are movably connected with the first curved pipe 6 at one end of the input concrete, and are also movably connected with the discharge pipe 9 on the first curved pipe 6 at the output concrete end, and the discharge pipe 9 Also flexibly connect flexible pipe 10 on it. Adjacent first curved pipes 6 are directly socketed end to end, and each section of first curved pipes 6 is movably installed on the boom 2 . Each first curved pipe 6 has a U-shaped project...

Embodiment 2

[0022] As shown in Figure 5, different from Embodiment 1, a reinforcing rod 17 is respectively arranged on both sides of the moving direction of the tackle in the rectangular frame of the first rectangular supporting space, and the reinforcing rod 17 is connected to the bottom of the first rectangular supporting space. The side 18 and the side 19 form a fourth triangular support space 20; the empty space is a trapezoidal space 22 formed between the reinforcement bar 17, the bottom 18 and the top 21 of the first rectangular support space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com