Covering layer without lead, cadmium of pigment without lead on ceramic glaze, and preparation method

A production method and technology for ceramic glaze, applied in the fields of pigments and ceramics, can solve the problems of poor color adaptability of pigments, poor chemical stability, large thermal expansion coefficient, etc., and achieve the production method that is simple and easy to operate, easy to master, and low in baking temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment.

[0037] See Table 1 for the ingredients, weight percent composition and main production process parameters of Examples 1-8 of the lead-free pigment on ceramic glaze of the present invention.

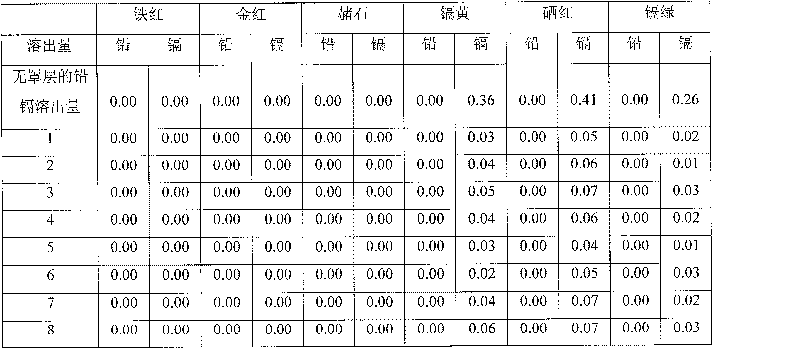

[0038] With the same color and the template of the same picture decorated with lead-free pigments on the ceramic glaze, the lead-free and cadmium-free cover layer processed and decorated with the embodiment 1~embodiment 8 shown in table 1 respectively and no lead-free and cadmium-free For the cover layer sample, the dissolution amount of lead and cadmium mg / dm is measured according to the method of ZBY24006-89 2 See Table 2 for comparison.

[0039] Decorate with the lead-free pigment on the ceramic glaze and process and decorate the same color and the model plate of the same picture with the lead-free and cadmium-free cover layer that the embodiment 1~embodiment 8 shown in table 1 is made, cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com