Circulation type super low temperature air cooler

An ultra-low temperature, cooling fan technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high energy consumption, evaporator frosting, and unsatisfactory effect, and achieves compact structure and high output. The effect of smooth wind and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

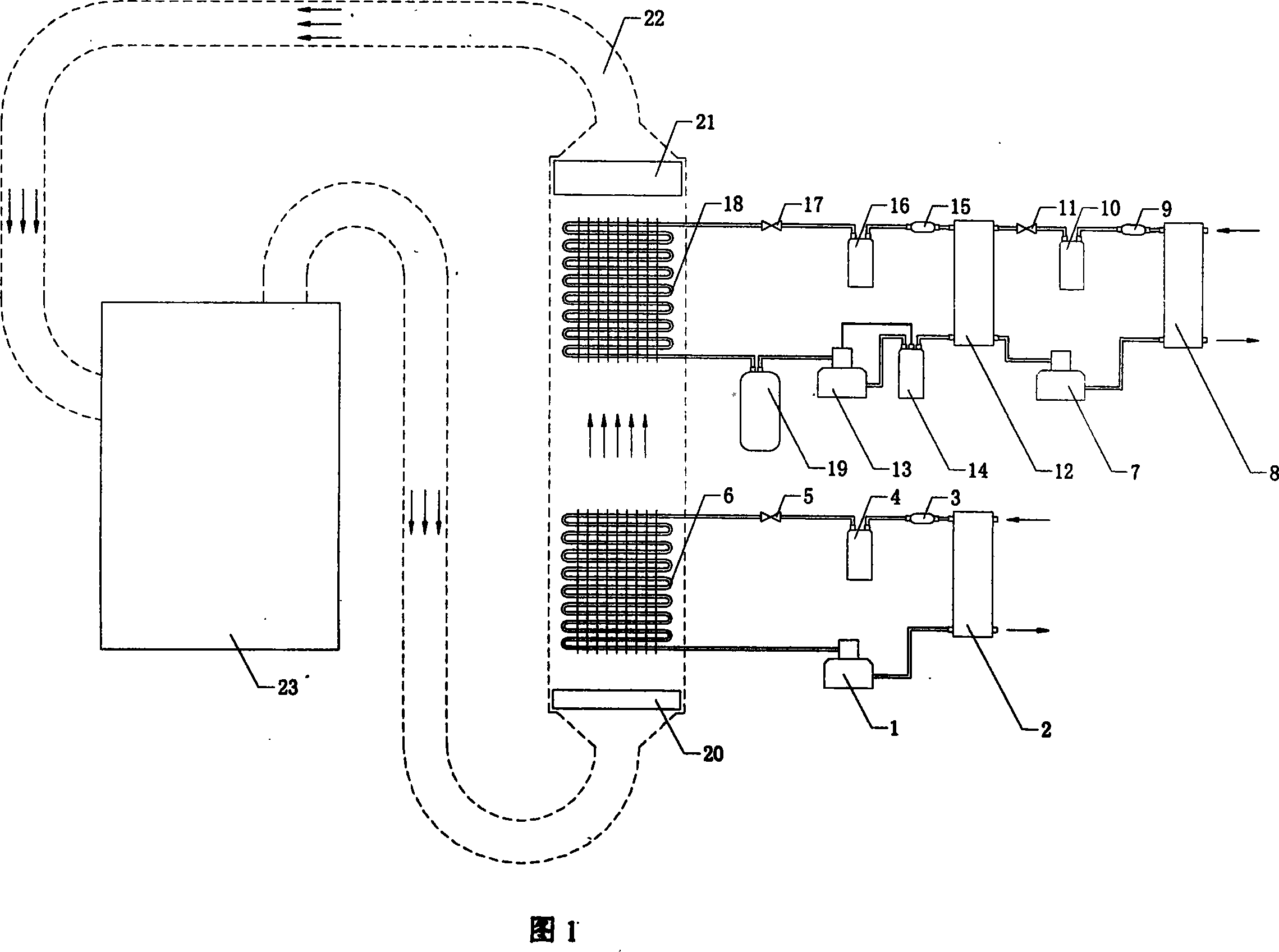

[0013] Referring to FIG. 1 , the present invention is a circulating ultra-low temperature air cooler, which is mainly composed of a single-stage compression refrigeration system, a cascade refrigeration system, an air filter 20 and a fan 21 . The single-stage compression refrigeration system is mainly composed of a refrigeration compressor I1 , a condenser 2 , a dry filter 3 , a liquid receiver 4 , a throttle valve 5 and an evaporator 6 . Refrigeration compressor I1, condenser 2, dry filter 3, liquid receiver 4, throttle valve 5 and evaporator 6 are sequentially connected with copper tubes to form a strictly closed loop I, pressure test, leak detection, vacuuming Finally, a certain amount of refrigerant I is charged to form a single-stage compression refrigeration system.

[0014] The cascade refrigeration system is mainly composed of refrigeration compressor II7, condenser 8, dry filter 9, liquid receiver 10, throttle valve 11, evaporative condenser 12, refrigeration compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com