Soft measuring method for large boiler oxygen content in exhaust smoke

A large-scale boiler and oxygen content technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as uneven distribution of oxygen content in flue gas, poor dynamic characteristics, and increased possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

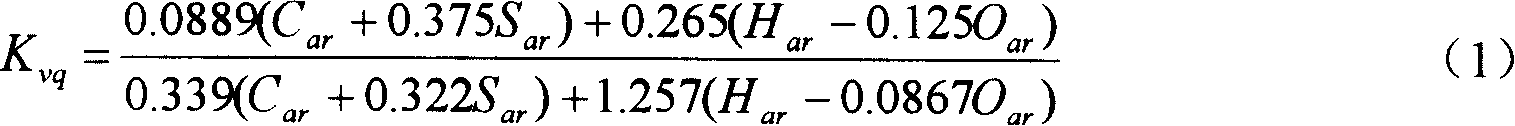

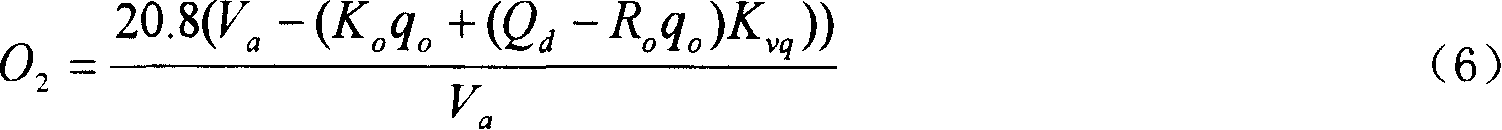

[0034] Embodiment: a kind of soft measuring method of oxygen content in flue gas of large-scale boiler, it comprises the following steps:

[0035] A. Approve the accuracy of the original signal

[0036] serial number

signal name

unit

the symbol

1

main steam temperature

℃

t s

2

main steam pressure

MPa

p s

3

Feed water temperature

℃

t w

4

main steam flow

Kg / s

q s

5

reheat steam temperature

℃

t r

6

reheat steam pressure

MPa

p r

7

High pressure cylinder exhaust temperature

℃

t l

8

exhaust temperature

℃

t p

9

cold air temperature

℃

t 0

10

Boiler total air volume

m 3 / s

V a

11

Drum pressure

MPa

p d

12

fuel flow

Kg / s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com