Flat vibration motor

A flat vibrating motor and vibrating force technology, which is applied in the direction of electric components, manufacturing motor generators, casings/covers/supports, etc., can solve the problem of complex manufacturing and assembly processes of flat vibrating motors, inability to maintain sufficient pressure, and reduced elasticity and other problems to achieve the effect of preventing swing or deformation, increasing output and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

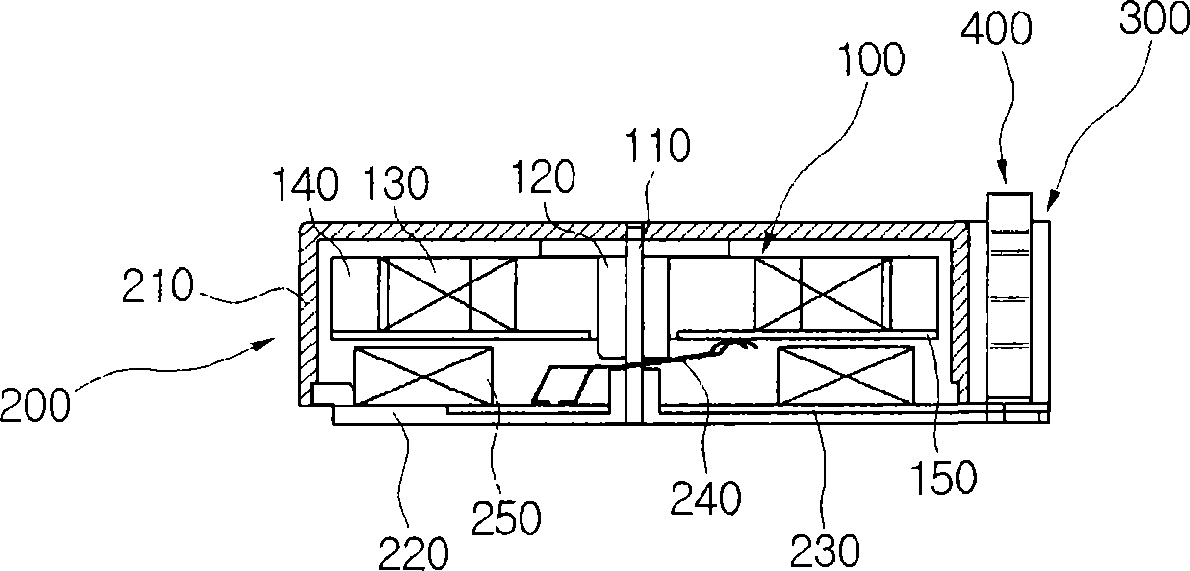

[0064] A detailed description will now be given of a flat vibration motor according to a first embodiment of the present invention with reference to the accompanying drawings.

[0065] Figure 4 is an exploded perspective view showing how the base portion 300, the terminal 400, and the stator portion 200 of the flat vibration motor according to the first embodiment of the present invention are assembled.

[0066] refer to Figure 4 , a fixing bracket 260 for supporting the base part 300 is formed at a side of the lower case 220 of the stator part 200 .

[0067] The fixing bracket 260 is a rectangular plate, and the second circuit board 230 is disposed on its top surface.

[0068] The terminal 400 includes a contact portion 410 , an elastic portion 420 and an engaging portion 430 . In the first embodiment of the present invention, two terminals 400 are provided, and the two terminals are arranged symmetrically opposite to each other on the second circuit board 230 . However...

no. 2 approach

[0094] A detailed description will be given below of a joint structure of the base part 300', the terminal 400', and the stator part 200' according to the second embodiment of the present invention with reference to the accompanying drawings.

[0095] Figure 7 is an exploded perspective view showing how the base part 300', the terminal 400' and the stator part 200' of the flat vibration motor according to the second embodiment of the present invention are assembled; Figure 8 is a perspective view showing a base portion 300' coupled with a terminal 400' of a flat vibration motor according to a second embodiment of the present invention.

[0096] refer to Figure 7 with 8 , the stator part 200' is formed with a fixing bracket 260 protruding from the lower case of the stator part 200'. The fixing bracket 260 is a rectangular plate, and has the second circuit board 230 fixed thereon.

[0097] The terminal 400' includes a contact portion 410, an elastic portion 420 and an eng...

no. 3 approach

[0117] Figure 9 is an exploded perspective view showing how the base part 300", the terminal 400", and the stator part 200 of the flat vibration motor according to the third embodiment of the present invention are assembled.

[0118] refer to Figure 9 , in the stator part 200 including the upper case 210 and the lower case 220, the lower case 220 has a fixed bracket 260 formed on its side, where the fixed bracket 260 is a rectangular plate supporting the bottom of the base part 300" and There is a second circuit board 230 thereon.

[0119] The terminal 400 ″ of the flat vibration motor according to the third embodiment includes a contact part 410 , an elastic part 420 ″ and an engaging part 430 ″, and is disposed on the fixing bracket 260 to be opposed to each other.

[0120] Two terminals 400" are provided in the third embodiment, but other numbers may be provided.

[0121] The joint part 430" may be connected to a part of the second circuit board 230 by soldering, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com