Flat plate film sludge concentration and treatment process

A treatment process and sludge concentration technology, applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, biological water/sewage treatment, etc., can solve high maintenance costs, poor economy, and large cost investment and other problems, to achieve the effect of small footprint, save floor space, and reduce work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

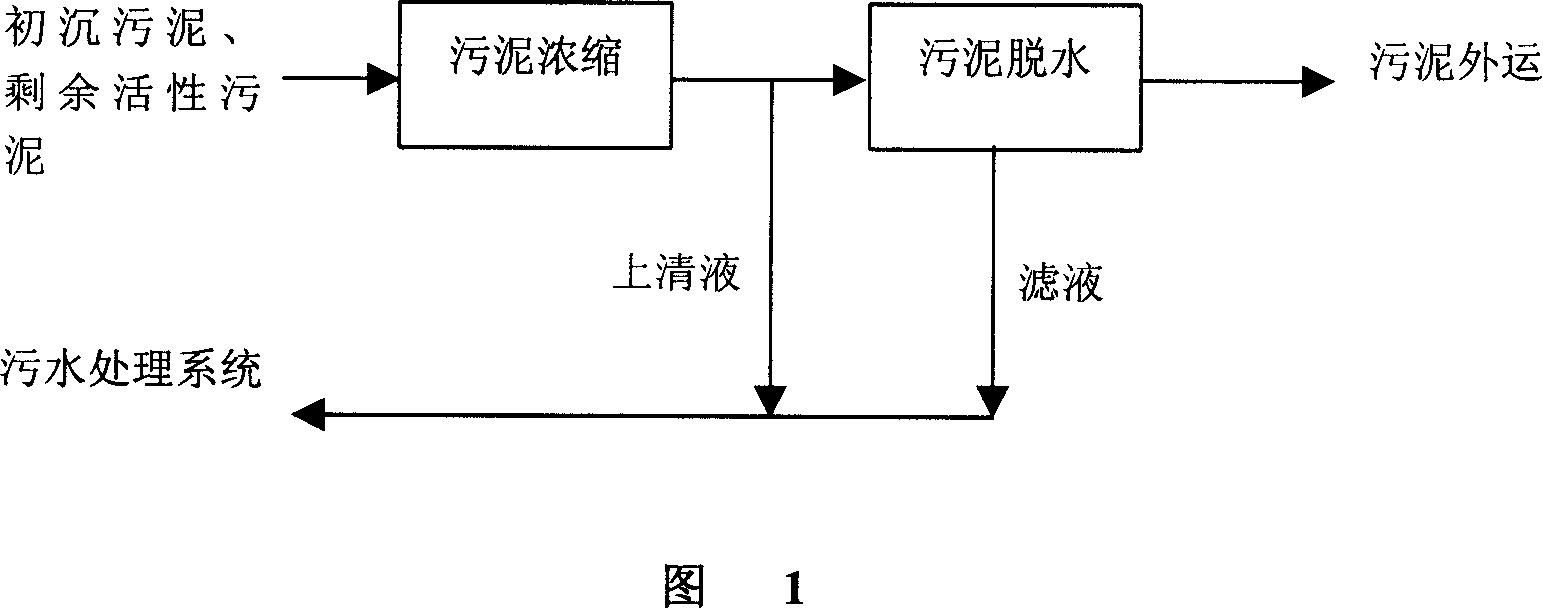

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

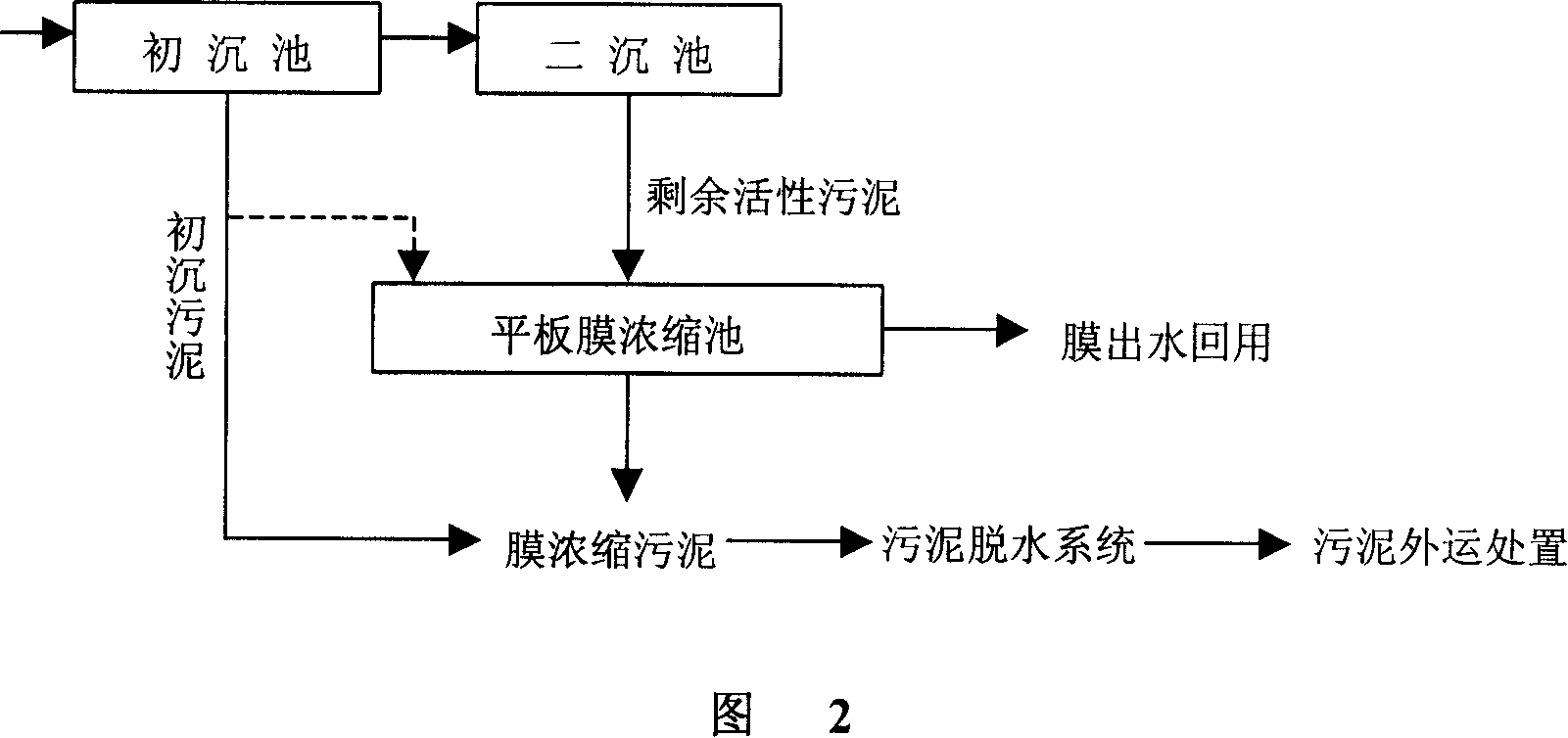

[0011] 1. Treatment of excess activated sludge

[0012] After the sewage is treated by the primary settling tank and the secondary settling tank, the remaining activated sludge discharged from the secondary settling tank enters the flat membrane concentration tank for concentration treatment. The input sludge concentration of the flat membrane sludge concentration tank: 3g / L, air-water ratio: 40 : 1, hydraulic retention time: 12h, operation mode of concentration treatment: continuous mud feeding and continuous water outlet in one mud discharge cycle; intermittent operation between each operation cycle. Membrane water flux up to 20L / m 2 .h, the water quality of the membrane effluent reaches the standard for reclaimed water reuse, and it can be reused directly, and the final sludge concentration can reach 20g / L. After the sludge treated in the flat membrane concentration tank is mixed with the sludge in the primary sedimentation tank, the solid content of the sludge is close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com