Minitype sea water desalination system water treatment technique

A water treatment, small-scale technology, applied in the direction of seawater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large land occupation, heavy equipment, complex process, etc., to reduce the cost of use, Easy to operate and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

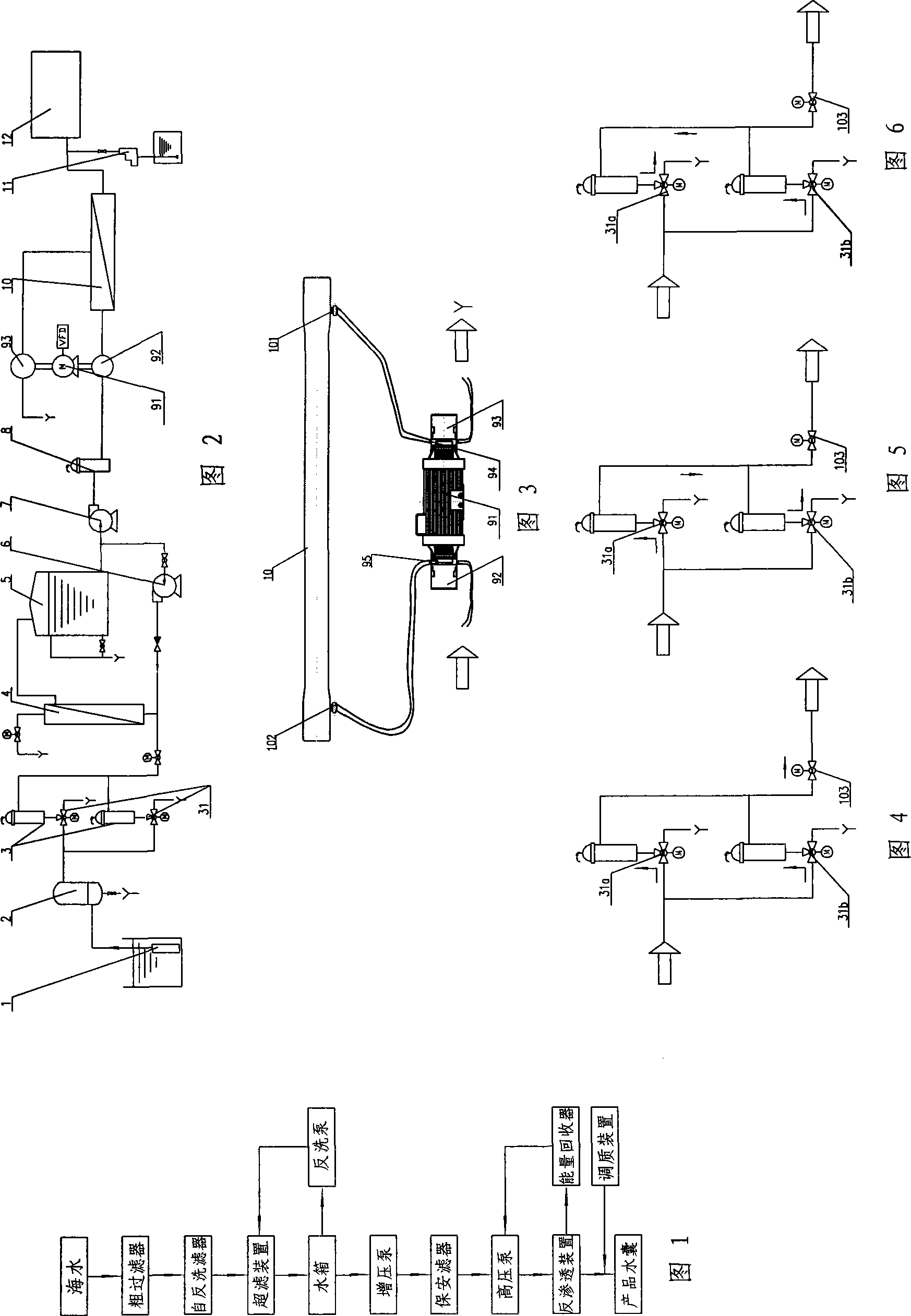

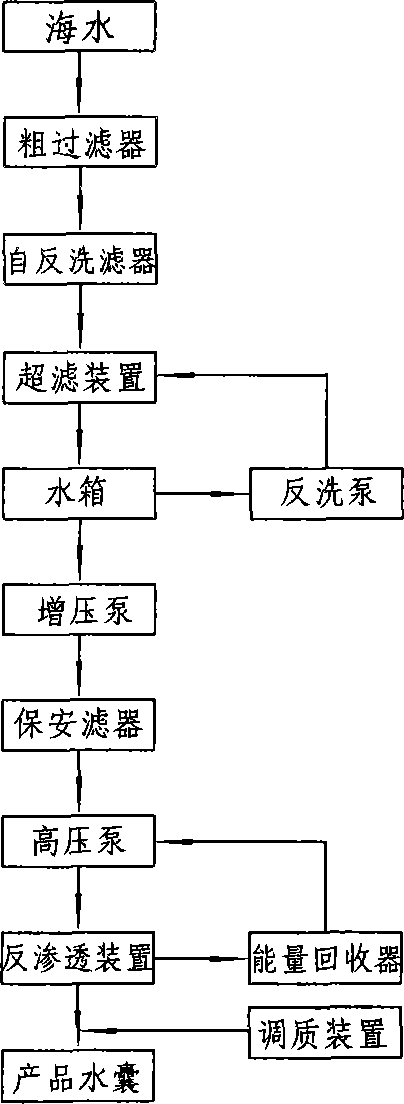

[0026] Refer to the attached drawings. The water treatment process of the small seawater desalination system provided by the present invention includes the following steps:

[0027] Step 1: The seawater is pressurized by the submersible pump 1 and enters the coarse filter 2 to remove large-size debris. If the seawater has a large turbidity, the coarse filter will be connected in multiple stages.

[0028] In step 2, two filters connected in parallel are used for processing, and the water inlet is equipped with an electric three-way valve. According to the set backwash sequence of the ultrafiltration device, the filter is adjusted by the electric three-way valve. Rotation is backwashed.

[0029] Step 3: The effluent is passed through the ultrafiltration device 4 to make the SDI value of the product water less than 3, which meets the requirements of reverse osmosis influent. The ultrafiltration product water enters the intermediate water tank 5, and a backwash pump 6 is specially set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com