Movable flange self-balanced flexible connection tube

A flexible nozzle, balanced technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, passing element, etc., can solve the problems of small axial displacement compensation ability, poor balance, difficult alignment of manufacturing errors, etc. Improve vibration isolation and noise reduction, reduce vibration and noise transmission, reduce installation workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

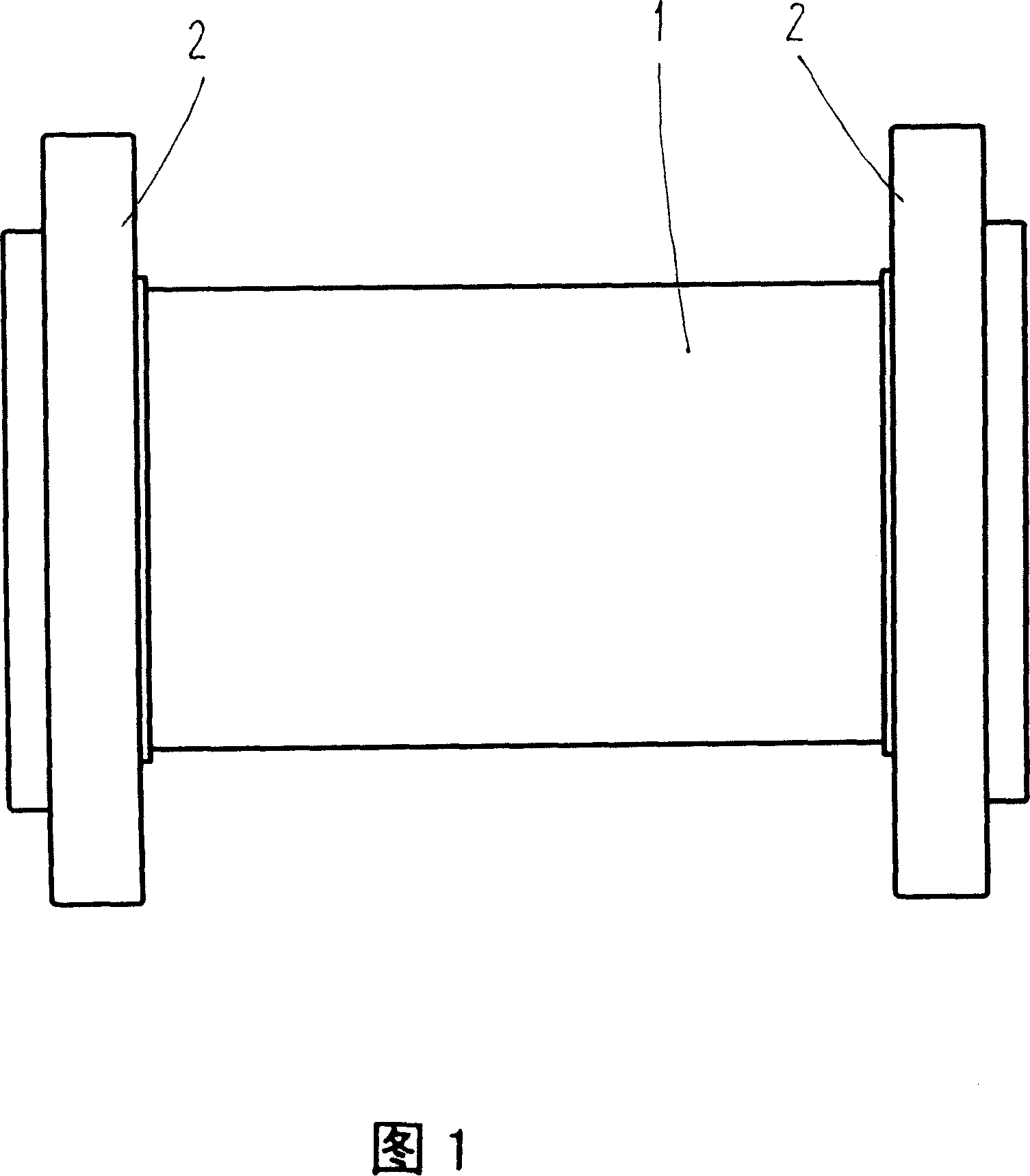

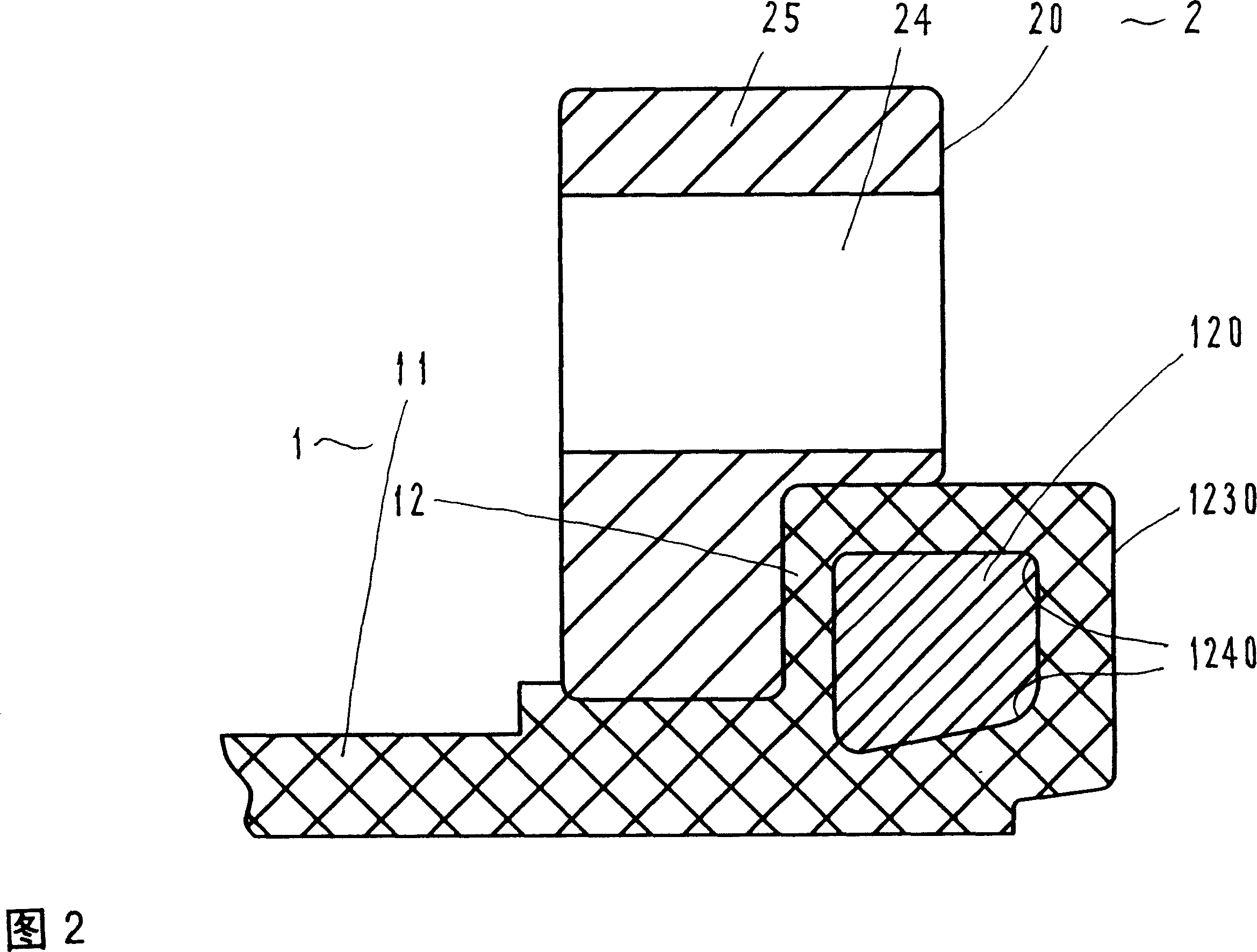

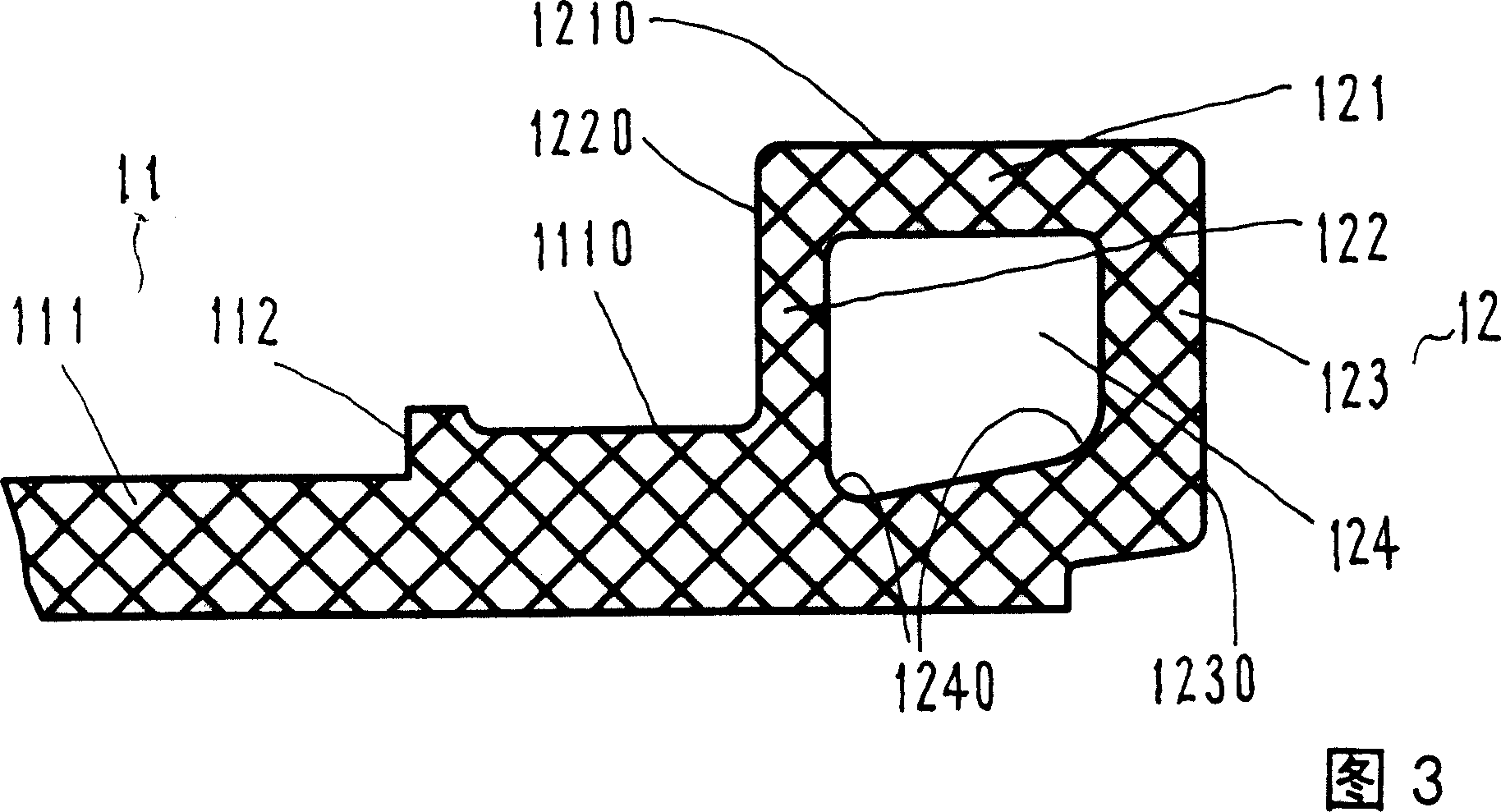

[0012] Referring to Figures 1 and 2, the active flange self-balancing flexible joint includes a hose 1 and a flange 2.

[0013] Rubber hose 1 is integrally formed by rubber and reinforcing materials. The inner rubber and flange joints are 50% natural rubber and 50% neoprene, and the outer layer is neoprene. The reinforcing material can be aramid fiber or For the steel wire, the winding angle of the fiber is determined by analyzing the best nozzle balance, fiber strength and nozzle stiffness. The pipe body 11 and the connection end 12 of the rubber hose 1 are integrated, and a flange 2 is respectively arranged on the two connection ends 12, forming the present invention. A unique loop-type flange structure, and advanced vulcanization process and corresponding molds can be used to ensure the elasticity and strength of the vulcanized rubber, the inner ring of the joint and the sealing rubber;

[0014] The cylinder body 111 of the pipe body 11 and the outer cylindrical surface 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com