Discrete low grade residue heat recovery boiler high temperature water-supply and air preheater system

A technology of waste heat recovery and boiler feed water, which is applied in the process transformation of boiler blast pipes and boiler feed water pipes, and can solve the problems of narrow application range, no heat recovery and utilization, and high initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

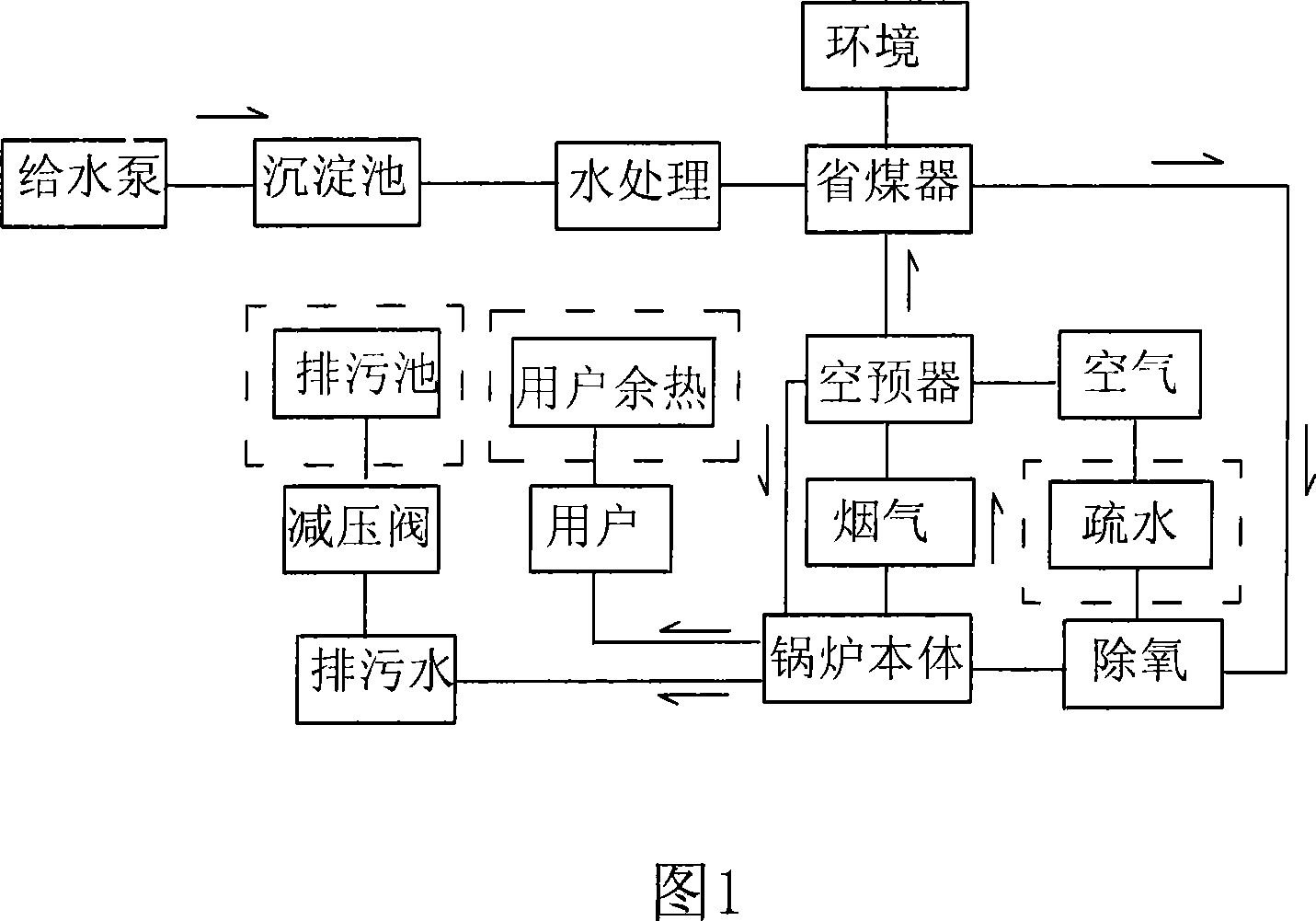

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

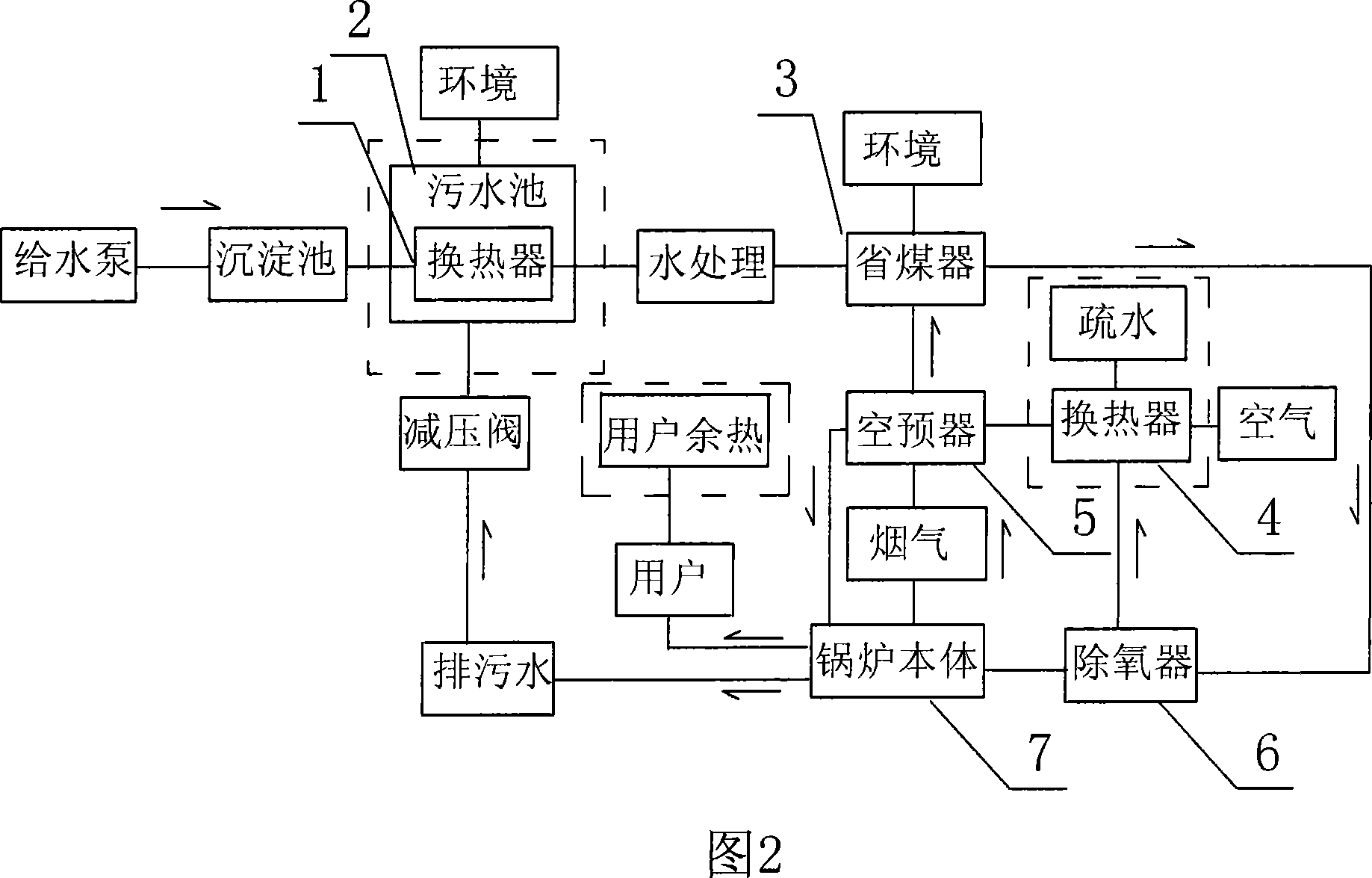

[0013] Referring to Figure 2, before the tap water supplied to the boiler enters the economizer 3, it is preheated by using the heat of the sewage discharged from the sewage tank of the boiler room. The tap water (water temperature is about 20 degrees) is preheated first, and the air primary preheating system adds an air and water heat exchanger 4 before the air enters the air preheater 5, and recovers boiler blowdown, oxygen removal and drainage, and user waste heat, etc. and other forms energy of. Preliminarily preheating the air can reduce the heat absorbed by the original air preheater and improve the efficiency of the economizer.

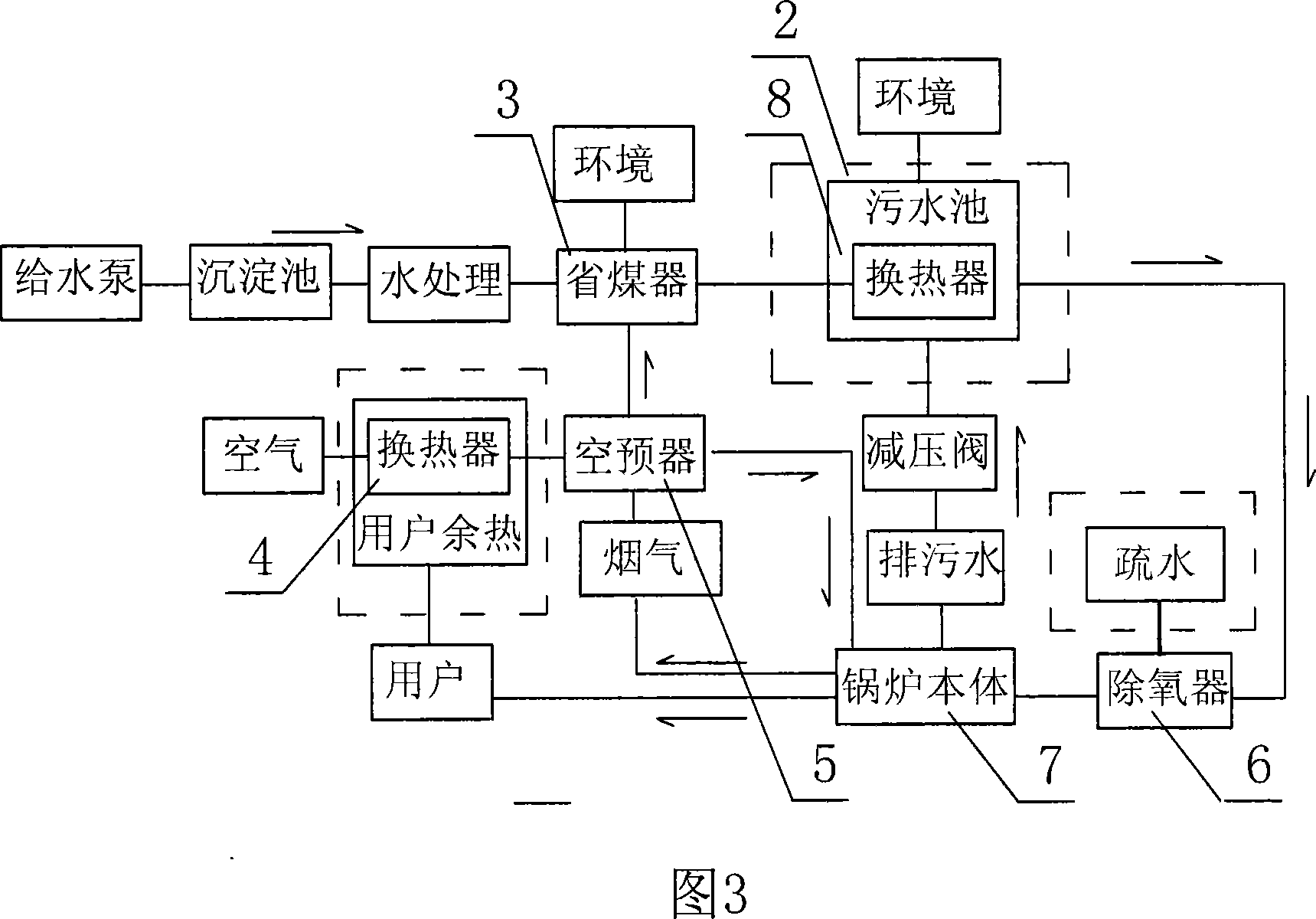

[0014] Referring to Fig. 3, a water-water heat exchanger 8 with an appropriate area is installed in front of the deaerator 6 after the boiler feed water enters the economizer 3 in the sewage tank 2, and the tap water passing through the economizer 3 is further heated, so that The feed water entering the boiler is increased from the original 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com