Multiple-passage dispersion reverse deduction microgranule tri-dimensional shape detector and detection method

A three-dimensional shape and micro-particle technology, applied in the field of particle optics, can solve the problems of sample preparation and manual observation that take a lot of time, and achieve fast and accurate inversion results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

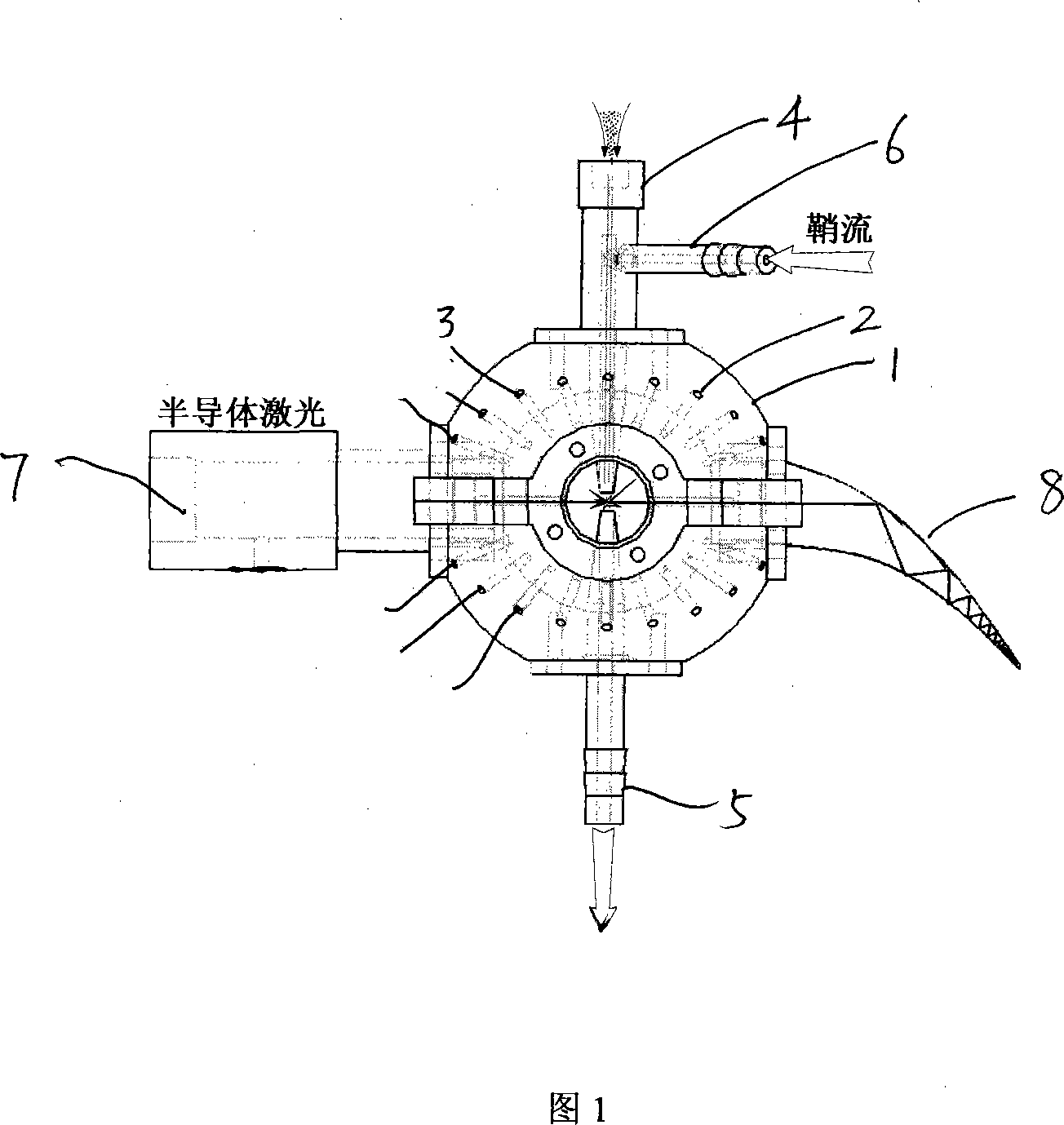

[0032] The multi-channel scattering inversion micro-particle three-dimensional shape detector is characterized in that it includes a scattering cavity 1, the surface of which is blackened, and the outer wall of the scattering cavity 1 is distributed with optical fiber jacks 2, and sampling holes are installed in the optical fiber jacks 2. The optical fiber 3, the top of the scattering cavity 1 is connected with the incident tube 4 of the sample particle beam, and its lower part is connected with the exit tube 5 of the sample particle beam on the same axis. A sheath flow tube 6, a plurality of modulating semiconductor laser modulators 7 are installed on the side wall of the scattering cavity 1, and the outgoing optical paths of each laser modulator 7 all intersect with the light that enters the scattering cavity 1 from the incident tube. A particle beam is injected, and an optical absorption tube 8 is installed on the opposite side of each laser modulator 7 .

[0033] The scatt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com