Spiral conveyer structure for horizontal centrifugal machine

A technology of screw conveyor and decanter centrifuge, used in centrifuges, centrifuges with rotating drums, etc., can solve the problems of difficult to reach sewage treatment plants, high moisture content of sludge, and slow space reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

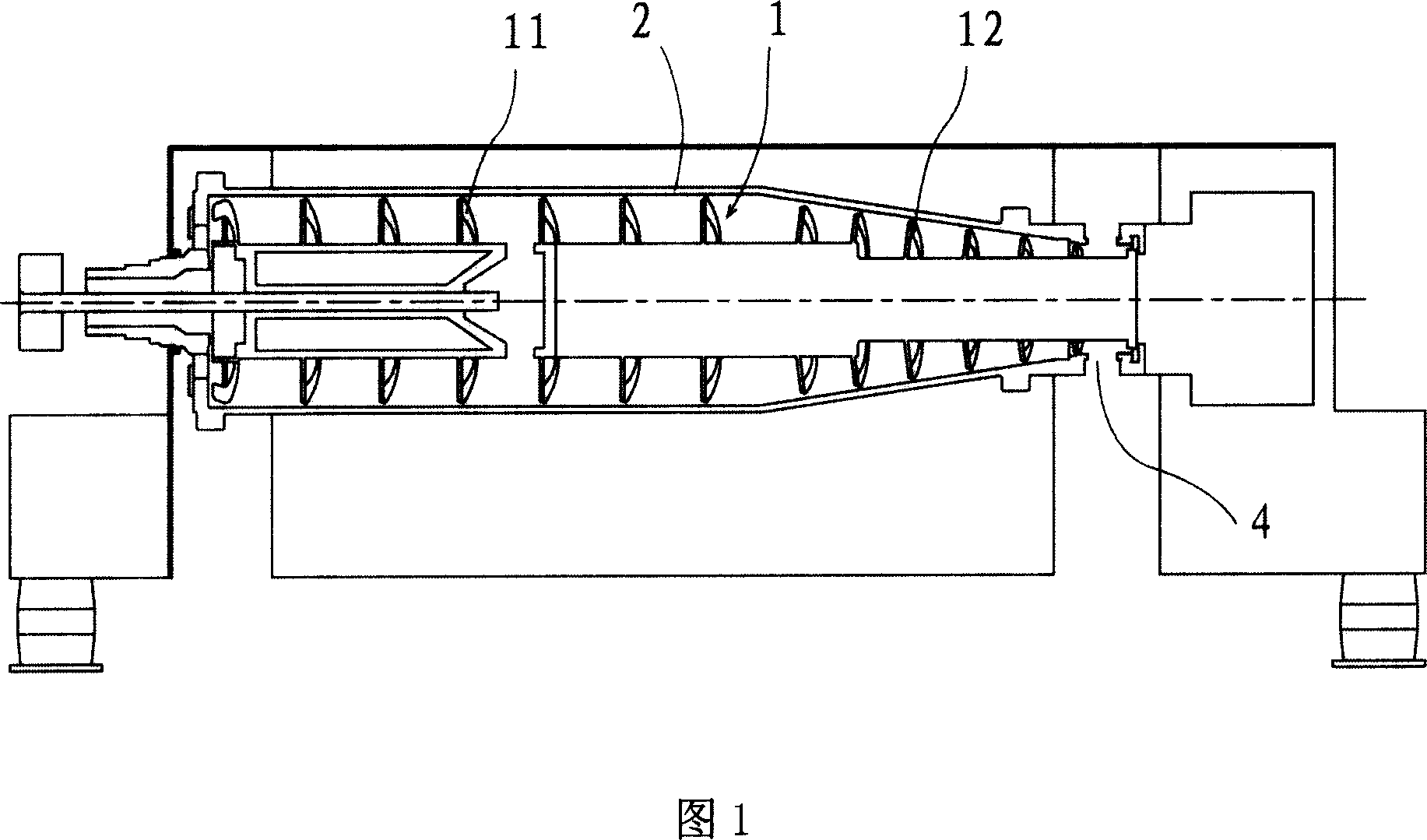

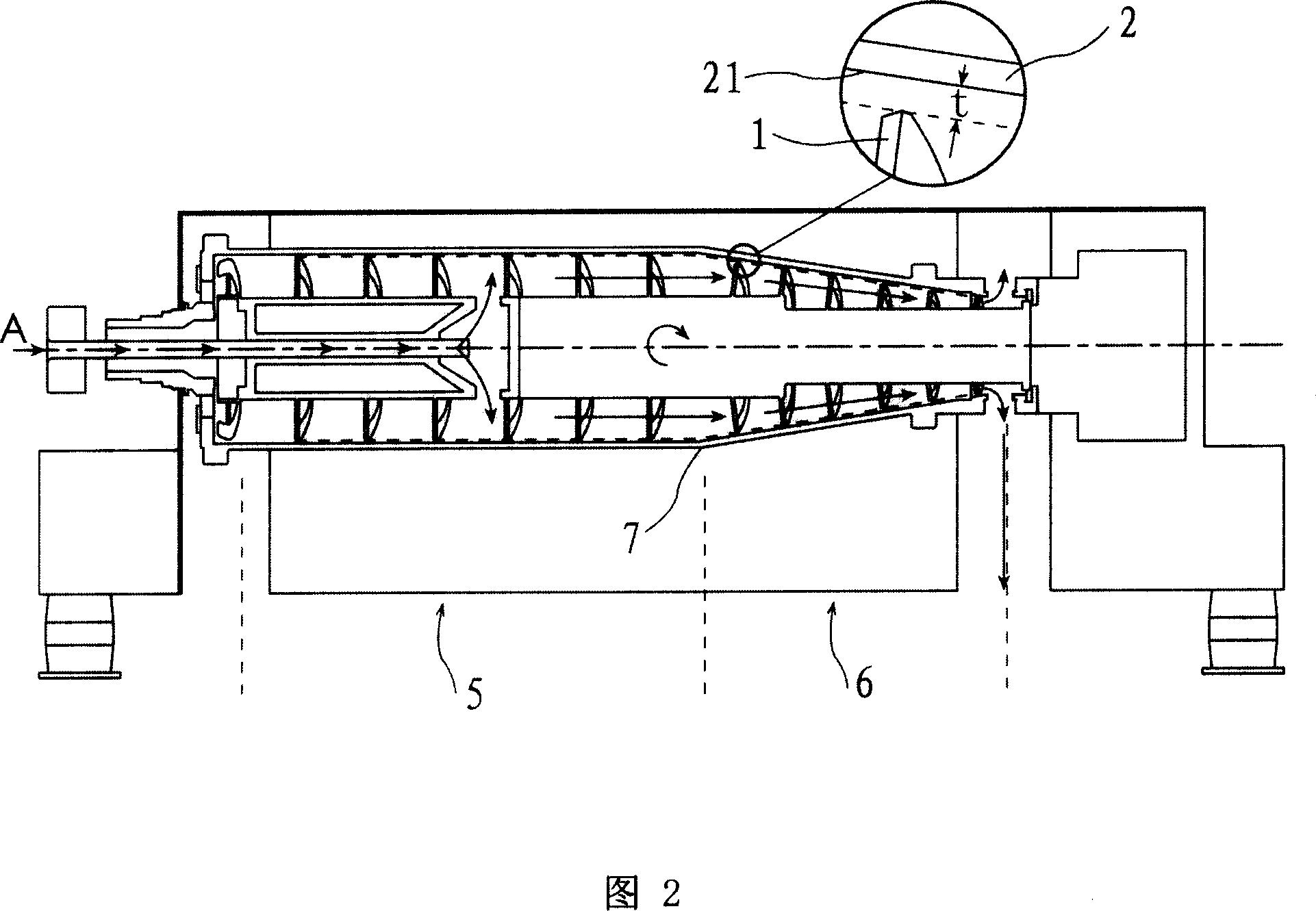

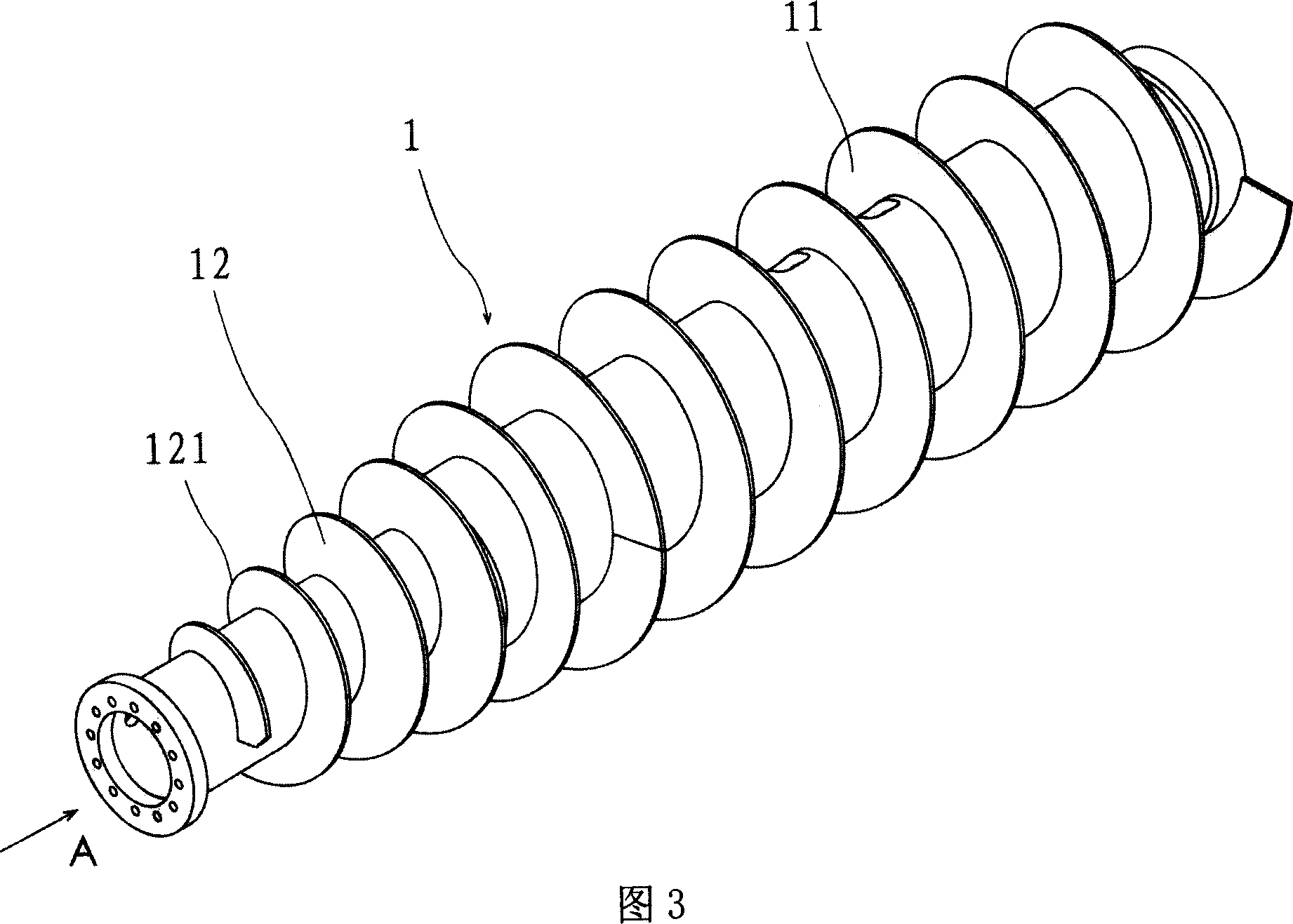

[0017] The screw conveyor structure of a decanter centrifuge according to the present invention mainly involves a screw blade 1 pivotally connected in the supporting drum 2, the screw blade 1 is composed of two naturally connected clarification blades 11 and drying blades 12. Partial composition, as shown in Fig. 1 and Fig. 2 is the decanter centrifuge structure schematic diagram that adopts screw conveyor structure of the present invention;

[0018] The screw conveyor of the decanter centrifuge adopts an equal-pitch design in the straight section (that is, the clarification area 5 of the centrifuge), that is, the pitch of the blade 11 of the clarification section of the screw blade 1 is S=δ (δ is a constant); the cone section of the screw conveyor Part (i.e. centrifuge drying area 6), the pitch is not a fixed value relative to the pitch of the straight section, and the variable pitch design is adopted. The variable pitch design includes two situations: ①, starting from the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com