Self-adaptive monitoring method for gas dissolved in oil of traction transformer, and the device thereof

A technology of dissolved gas in oil and traction transformer, which is applied in the field of on-line monitoring of dissolved gas in insulating oil of traction transformer, which can solve the problems of gas detection deviation, unsuitable traction transformer, insufficient recovery time, etc., and achieve stability and detection accuracy improvement , Overcoming the effect of concentration measurement and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

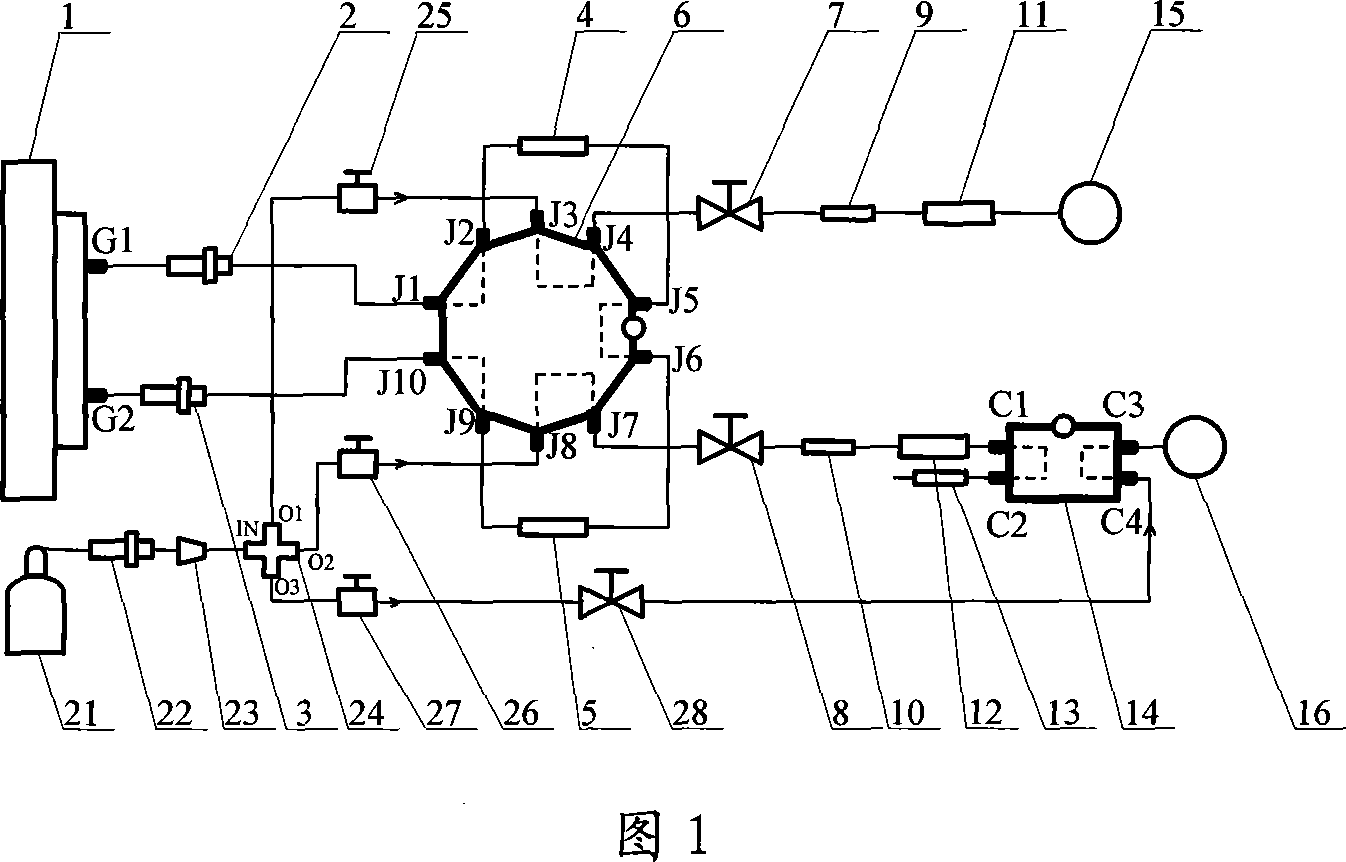

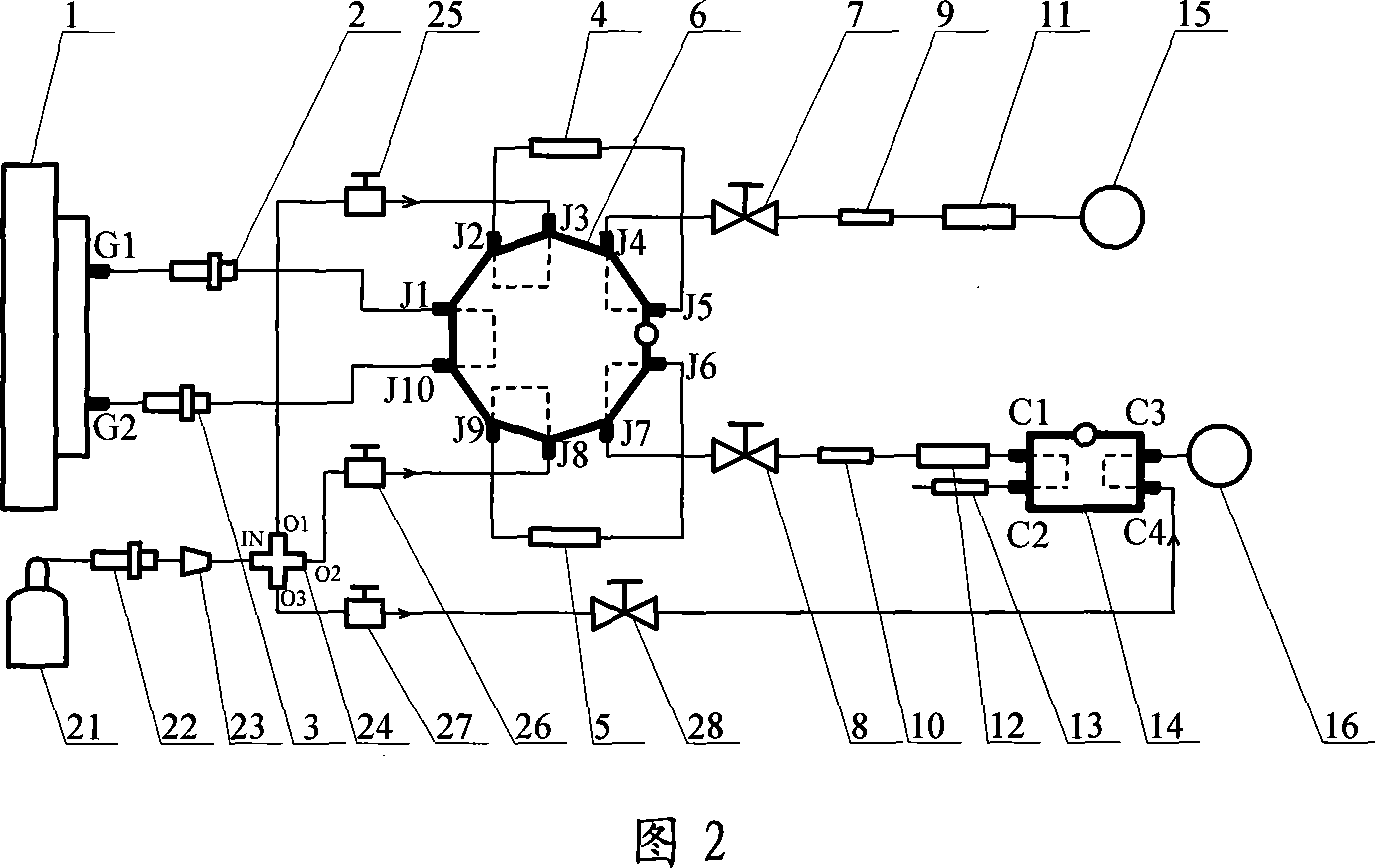

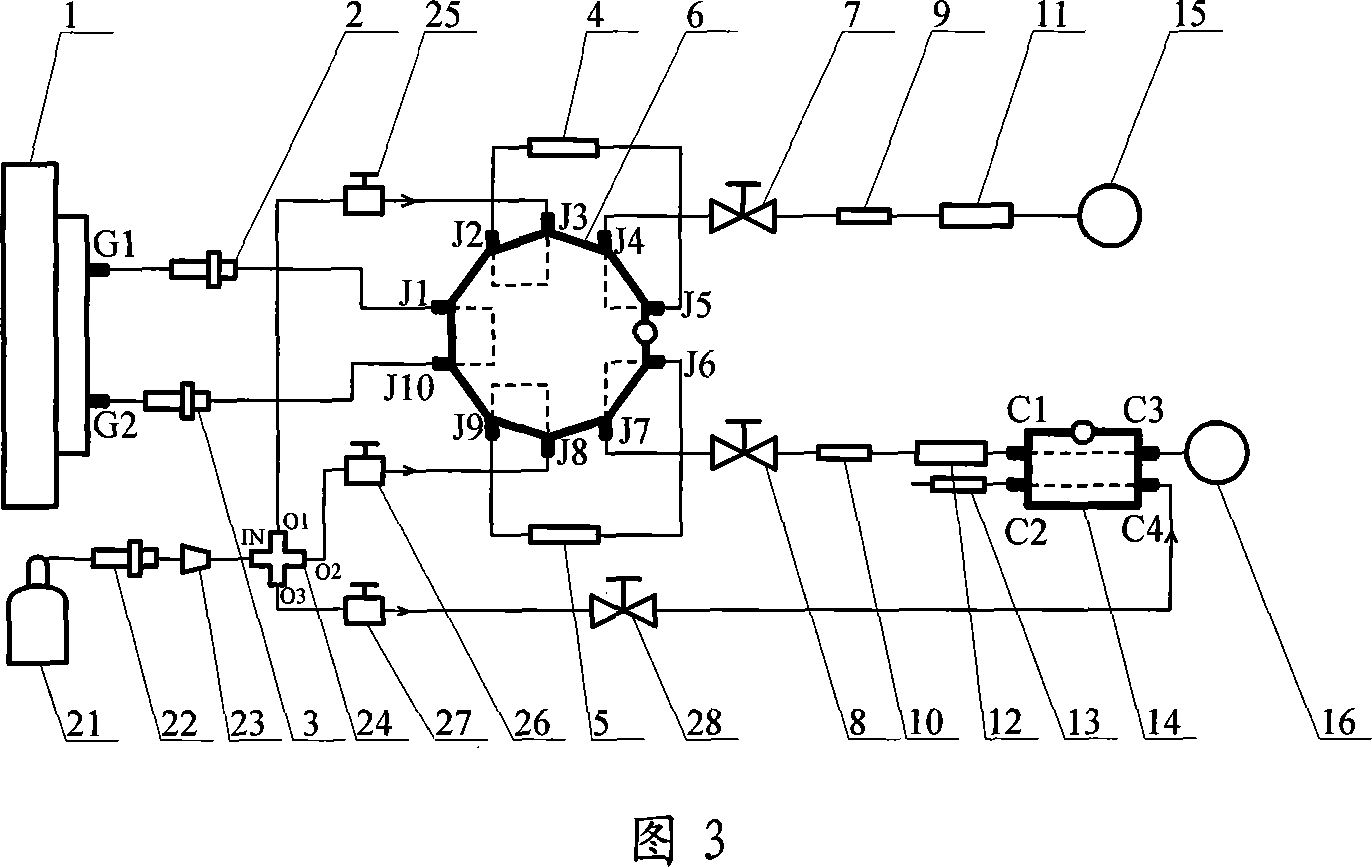

[0082] Figures 1 to 3 show that a specific structure of the device of the self-adaptive monitoring method for dissolved gas in traction transformer oil of the present invention is:

[0083] The composition of the gas collection branch is: the first output port G of the oil-gas separation device 1 1 , No. 1 solenoid valve 2, solenoid ten-way valve 6 first interface J 1 , the second interface J 2 , No. 1 quantitative tube 4, electromagnetic ten-way valve 6 fifth interface J 5 , the sixth interface J 6 , No. 2 quantitative pipe 5, electromagnetic ten-way valve 6 ninth interface J 9 , the tenth interface J 10 , No. 2 solenoid valve 3, the second output port G of oil-gas separation device 1 2 Followed in turn.

[0084] The composition of the high-concentration gas detection branch is: No. 1 quantitative tube 4, electromagnetic ten-way valve 6, fifth interface J 5 , the fourth interface J 4 , No. 1 needle valve 7, No. 1 gas block 9, No. 1 gas chromatographic separation colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com