Three-dimensional measuring machine for the shoe mould

A technology of three-dimensional measurement and shoe molding, which is applied to the measurement devices of feet or shoe lasts, footwear, and other applications. It can solve the problems of high trial processing costs, high physical energy consumption, and low efficiency, and achieve simple and convenient use of the machine. Installation Ease of use, lower entry level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

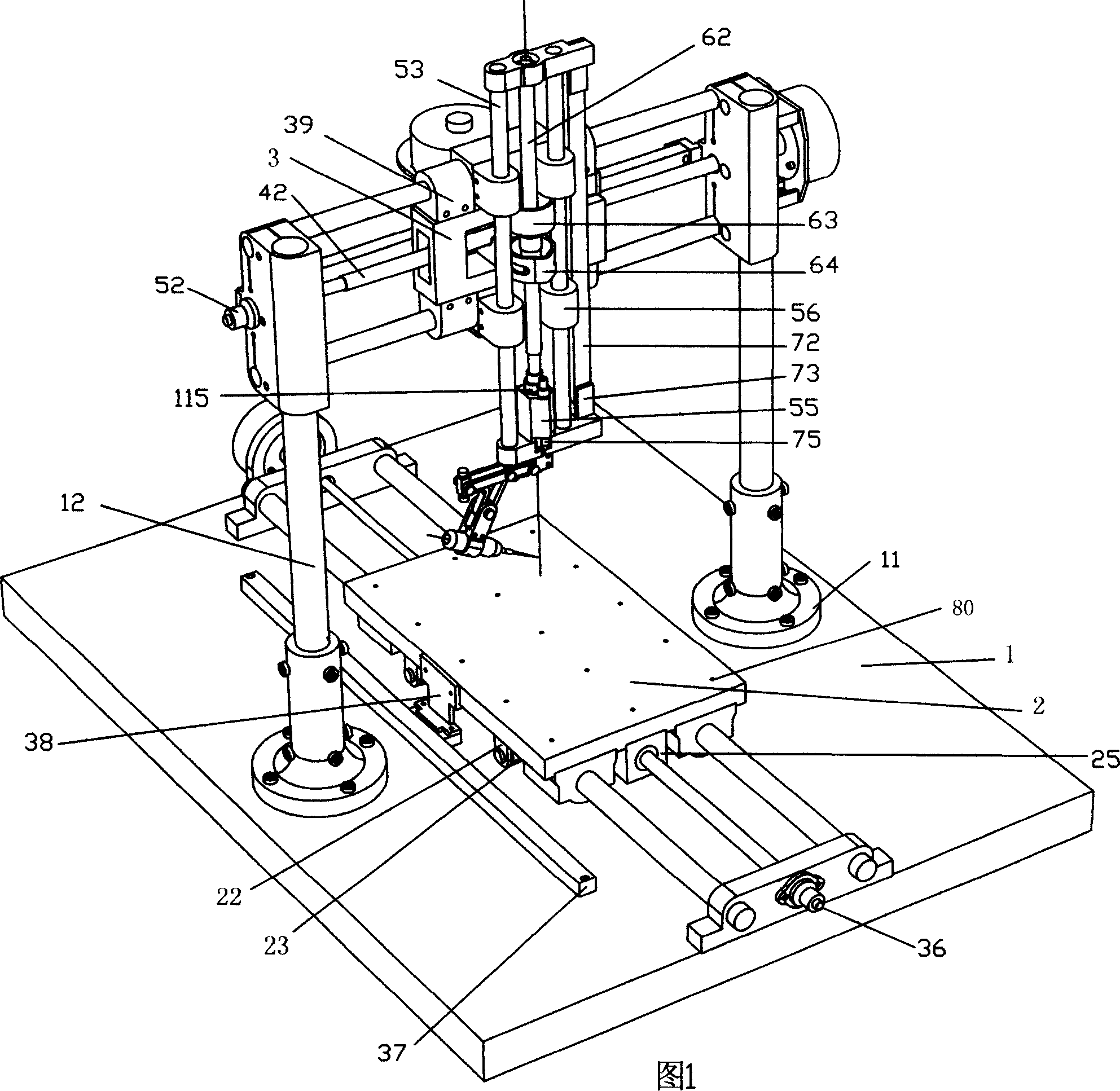

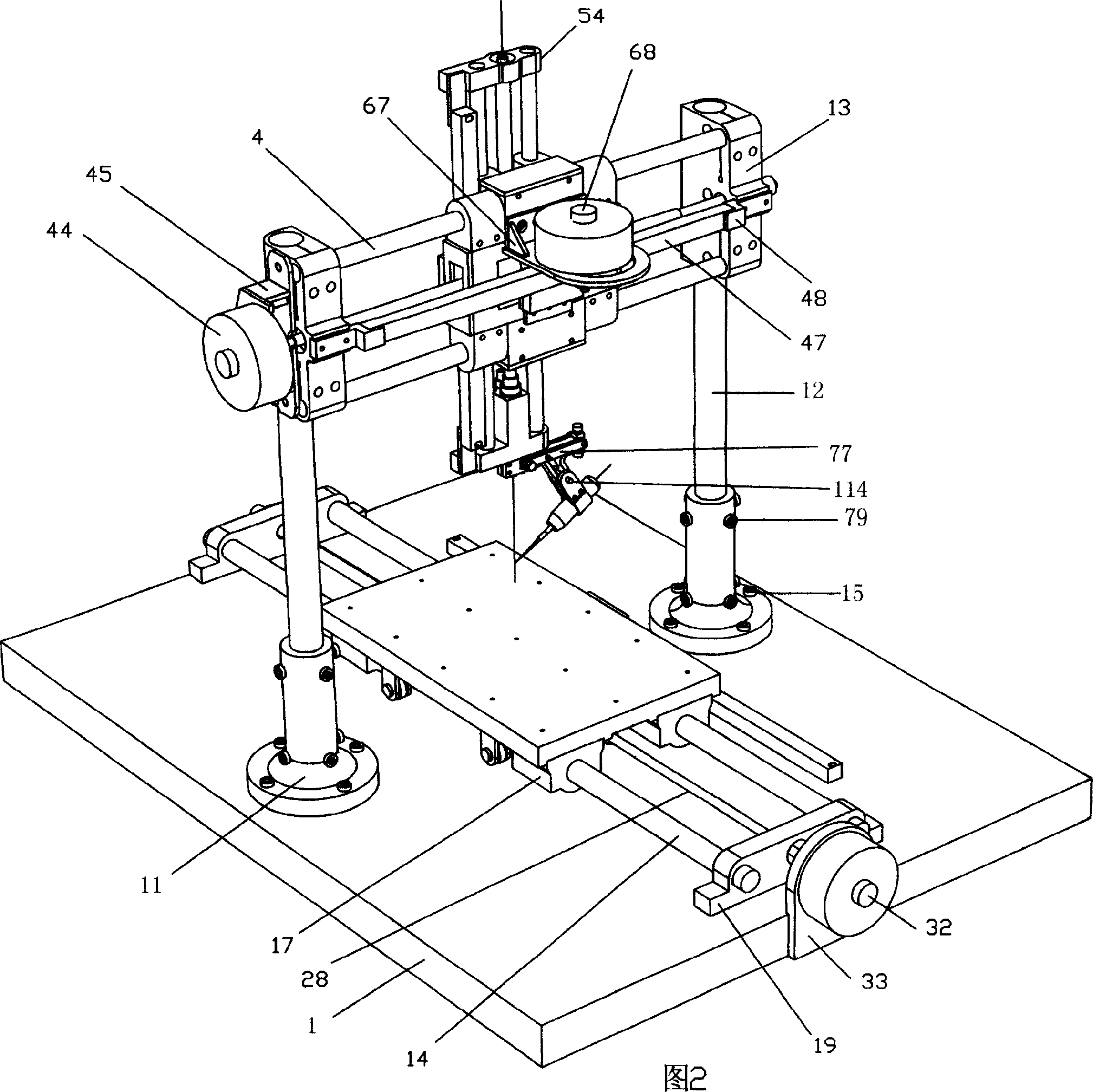

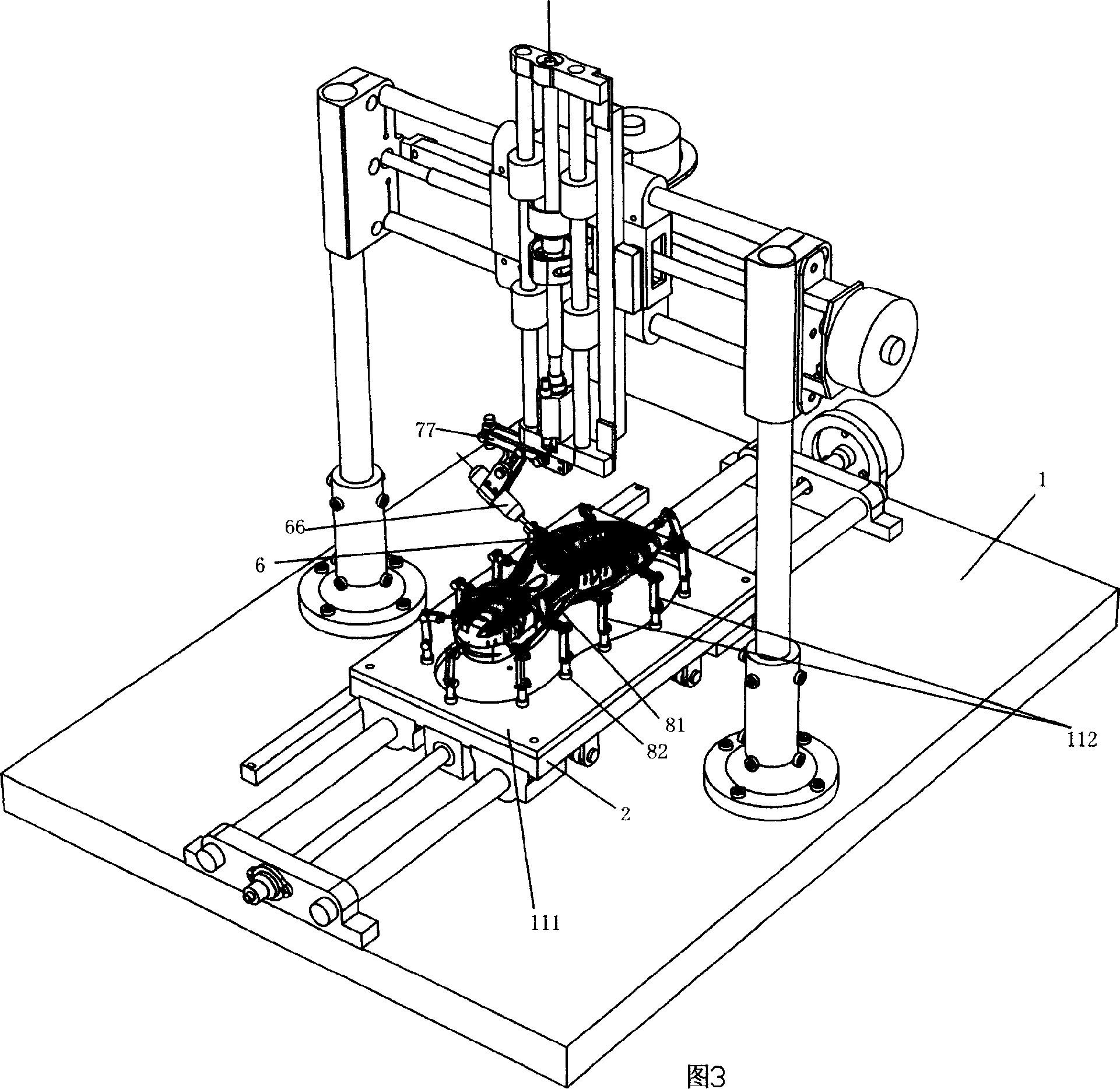

[0056] As shown in Fig. 3, the working principle of the present invention is: fix the sample shoe 81 on the surveying tool 82 according to the appropriate position, and then fix the surveying tool on the workbench 2 of the measuring machine through the part screw hole 80. When the control handle is manipulated, the three axes of the measuring machine can move accordingly. At this time, the position detection element parallel to the three axes of the machine—the grating can continuously send the position pulse signals of each axis to the digital display meter. The digital display meter has a built-in single-chip control circuit, which can convert these signals into digital coordinates and display them on the panel. In addition, the digital display meter can complete functions such as coordinate clearing and number setting, which are used to complete benchmark calibration before surveying and mapping and change the probe post-baseline calibration. During the surveying and mappin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com