Magnetic air thermal dissociation method and device for solid waste treatment

A solid waste and air heating technology, applied in the field of waste treatment, can solve problems such as difficult to control the combustion process, complex garbage components, environmental pollution, etc., and achieve significant adsorption effects, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and typical embodiments.

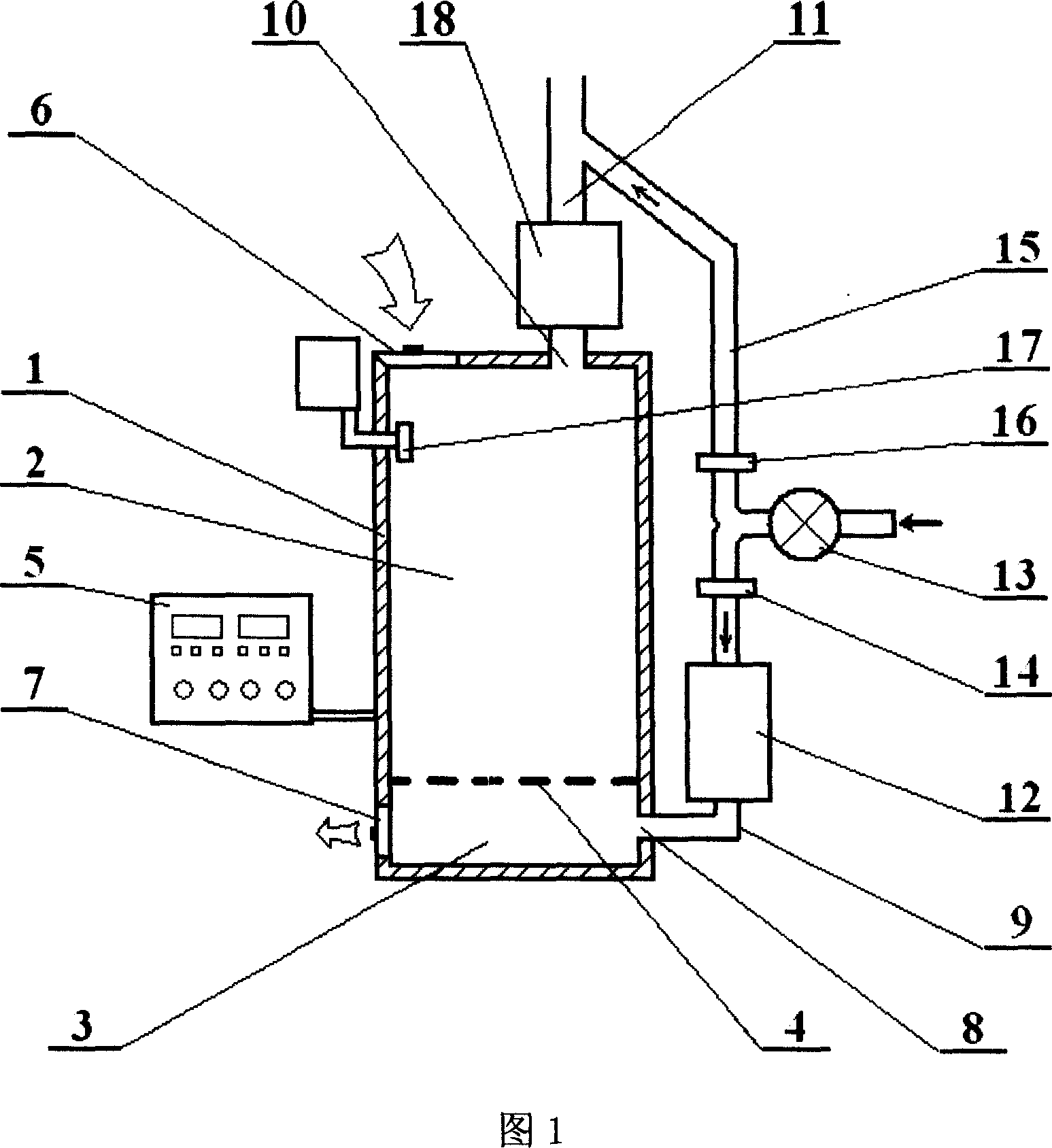

[0028] Figure 1 shows a magnetized air pyrolysis device for solid waste treatment. As an embodiment of the present invention, this magnetized air pyrolysis device can be made into small and medium-sized equipment, with a processing capacity of 0.5 to 10 tons. , Can be used for self-disposal of garbage in enterprises, hotels, residential communities, hospitals, schools, etc. The waste pyrolysis products are not used for regeneration, so a deodorizing tube is generally installed on the exhaust flue to absorb the vapors and smoke generated by pyrolysis. As an environmentally friendly and energy-saving device, the device can reduce the volume of solid waste to 1 / 100 in 3-4 hours; 1 / 300 in 6-8 hours; and 1 / 3000-1 / 5000 in 30 hours. Can be fed at any time. The device includes a furnace body 1, a processing chamber 2, a discharge chamber 3, a grate 4, an electrical cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com