Weld seam appearance, fused bath and seam near-infrared vision integral sensing checkout gear

A welding seam appearance and detection device technology, which is applied to measuring devices, welding equipment, optical devices, etc., can solve the problems that the welding seam appearance near-infrared sensing detection technology has not been solved, and achieve stable sensing quality and wide adaptability. , powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

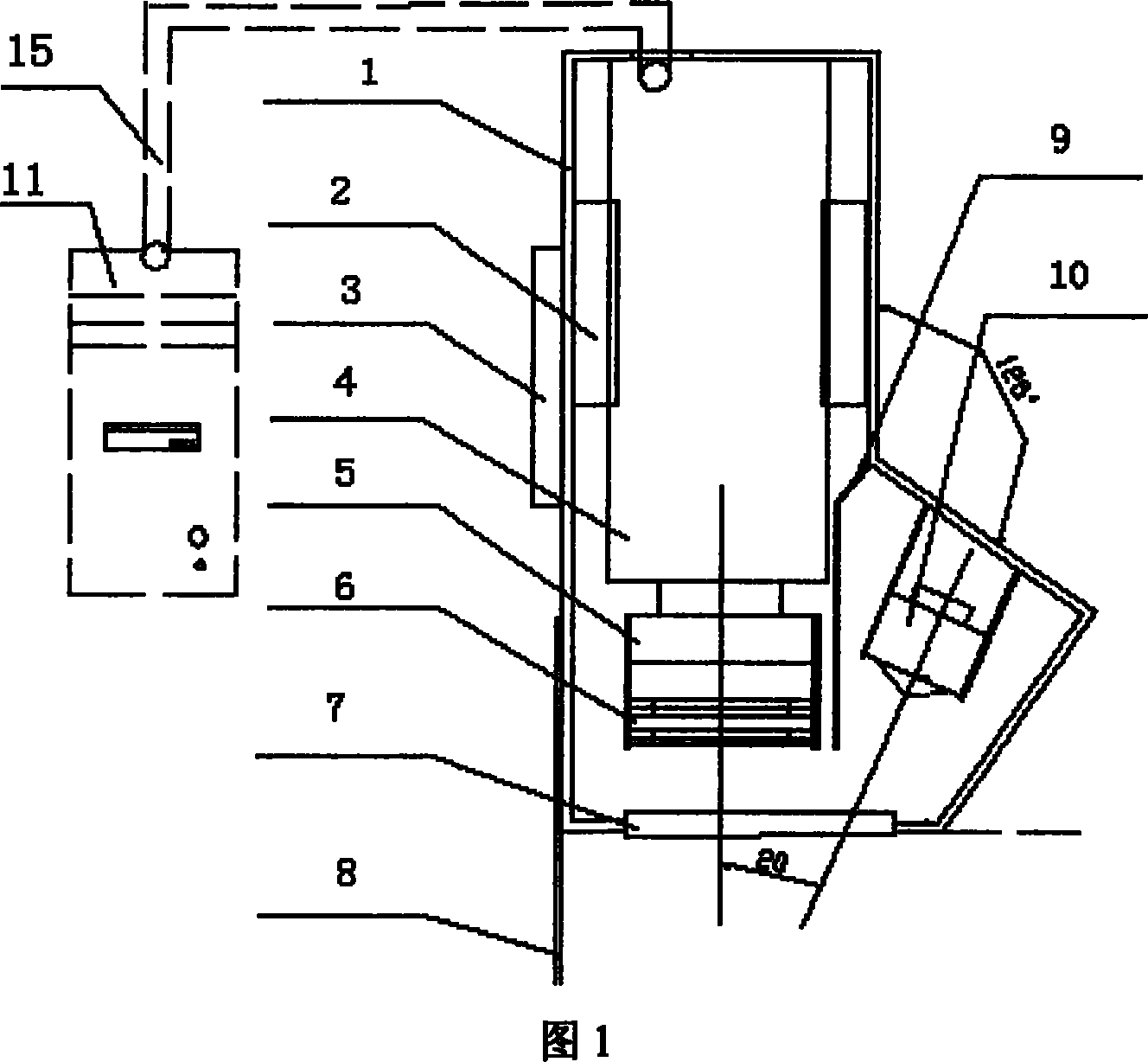

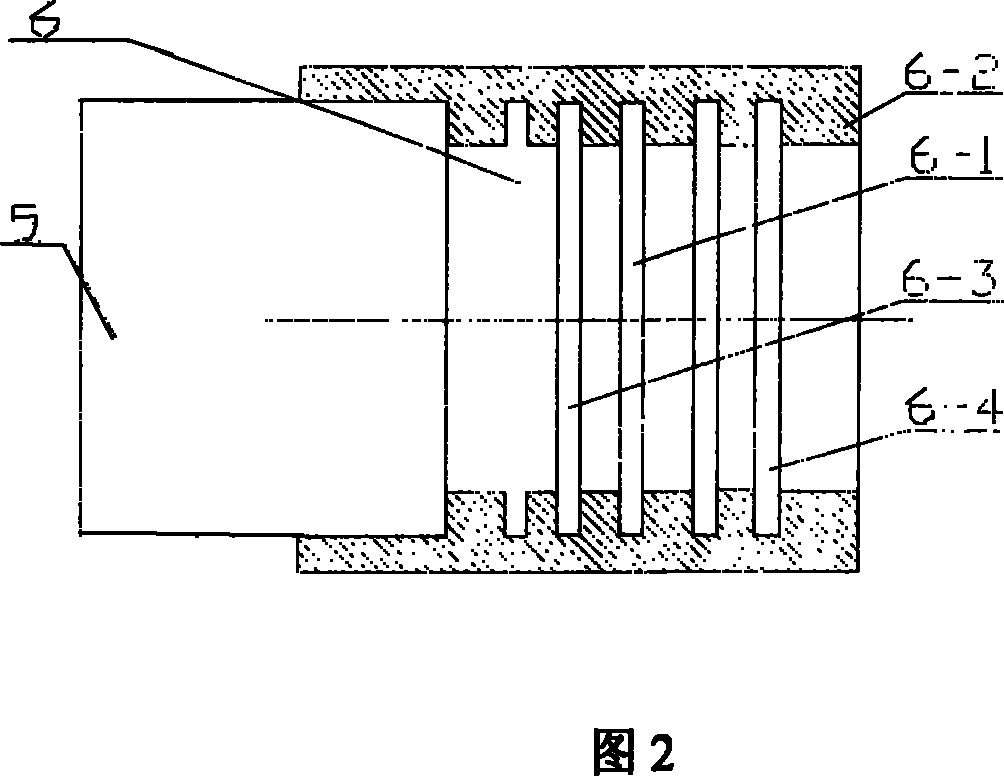

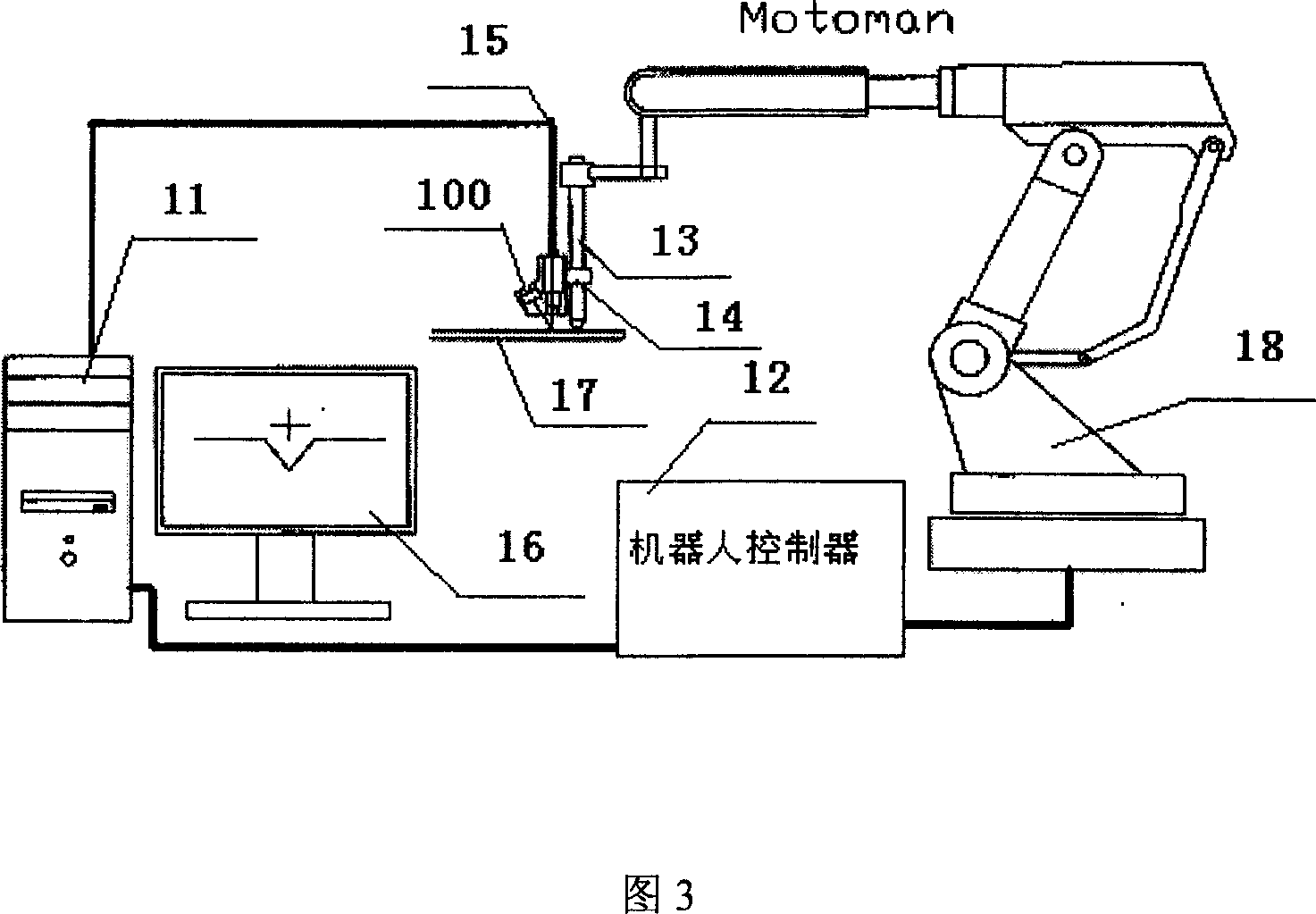

[0020] With reference to Fig. 1 and Fig. 2, the weld appearance, molten pool and seam near-infrared vision integrated sensing and detection device of the present invention includes a housing 1 arranged on a mounting frame 3 and an arc-blocking arc light connected to the housing 1 The arc shield 8, the near-infrared CCD sensor 4, the large focal length lens 5 with a focal length of 16-25 mm, the near-infrared narrow-band filter system 6 and the near-infrared laser 10 are arranged in an aluminum shielded housing 1 to form a whole, that is, the The near-infrared CCD sensor 4 is installed on the housing 1 through the fixing seat 2, and a large focal length lens 5 and a near-infrared narrow-band filter system 6 are arranged successively on the axis of the near-infrared CCD sensor 4. The near-infrared narrow-band filter system 6 The axis of the near-infrared laser ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Parallelism | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com