Electric-controlled head

A pan-tilt, electronic control technology, applied in the machine/stand, control using feedback, supporting the machine, etc., can solve the problems of stability and complicated and inaccurate operation, inaccurate rotation position, motor jitter, etc., to meet the High-precision display and controllable, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

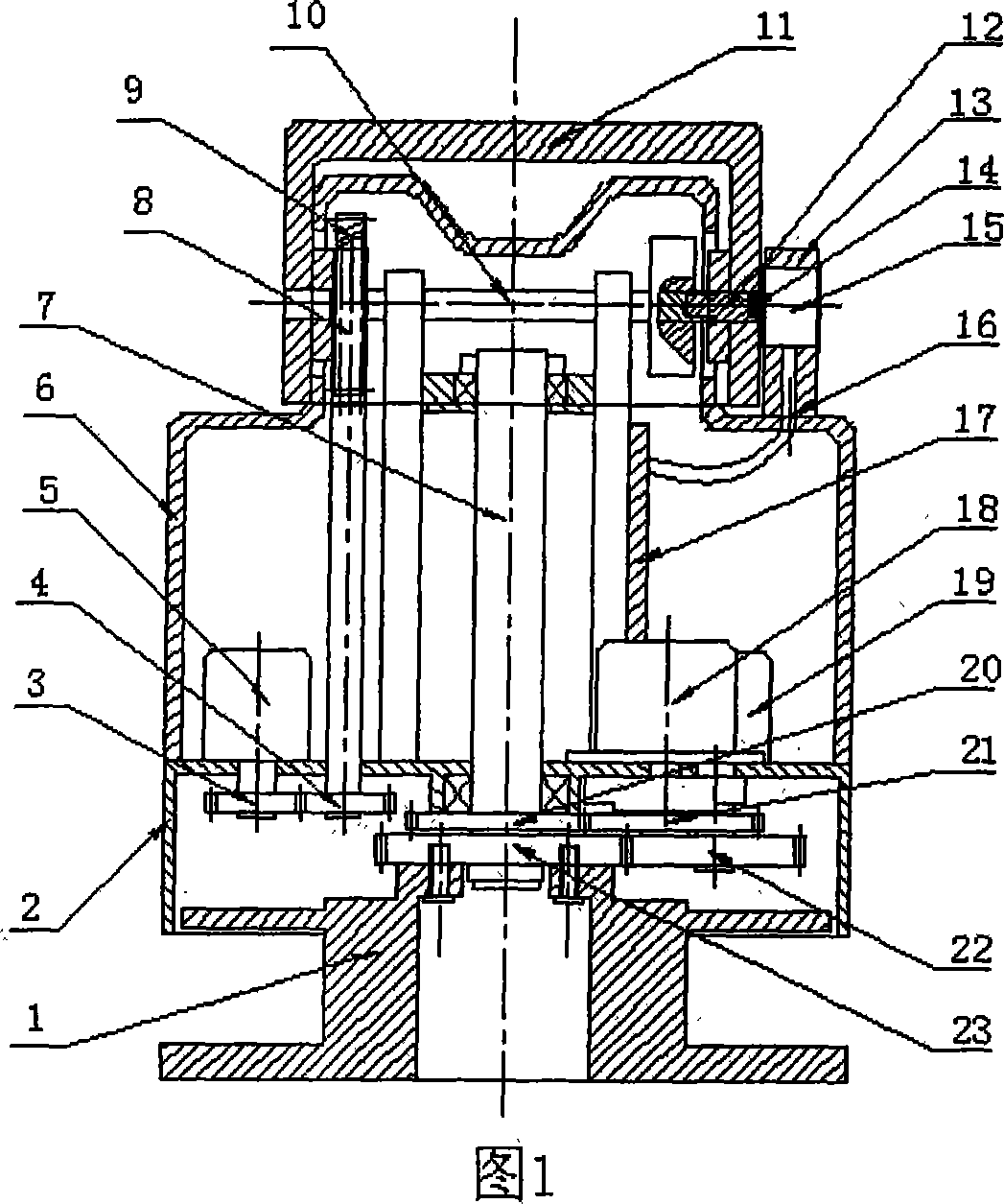

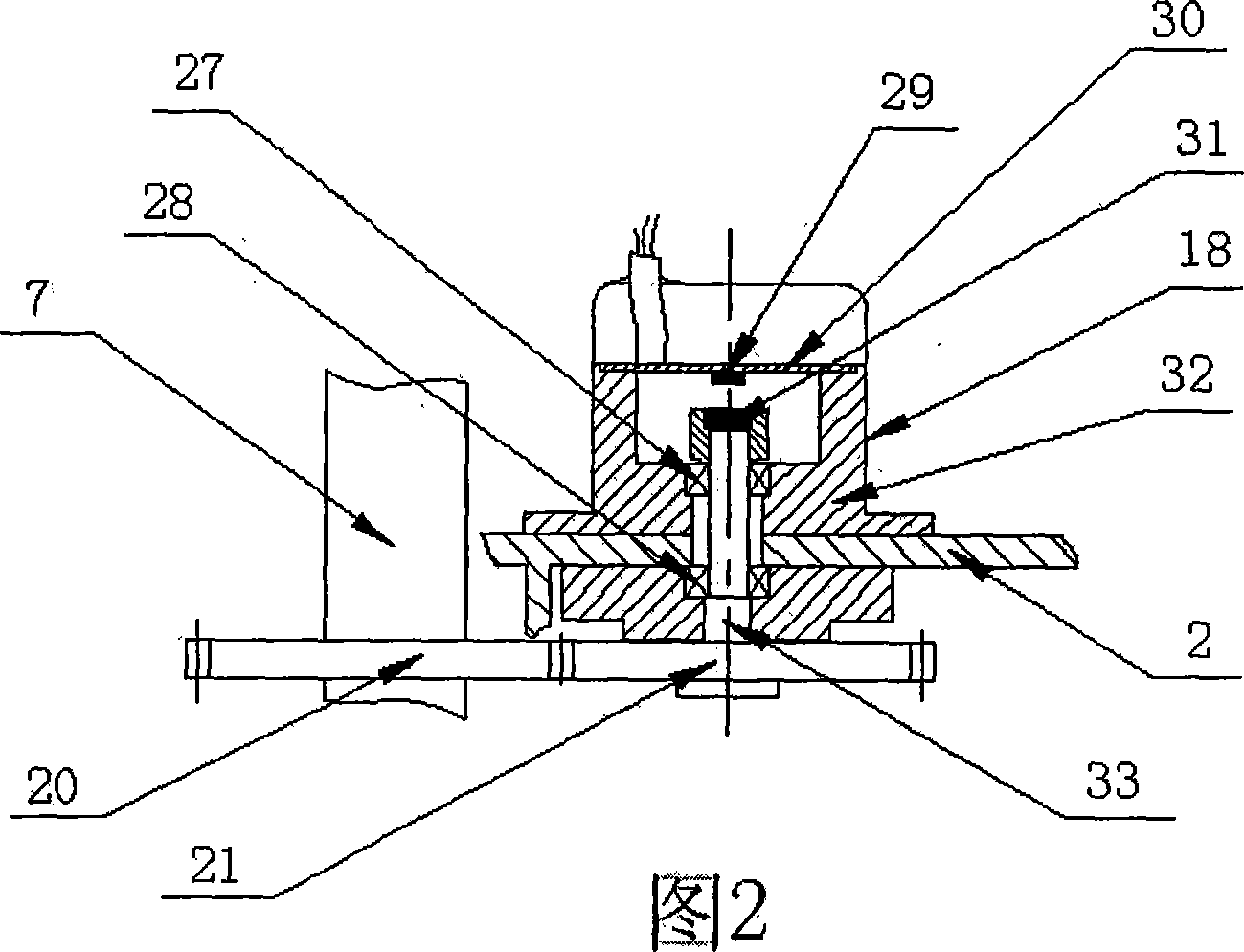

[0029] As shown in Figure 1, the structure of the integrated magnetic-sensitive angle sensor 18 used for plane rotation angle detection in the present invention is shown in Figure 2, and the sensor rotating shaft 33 is fixed on the outer end cover 32 by two rotating bearings 27,28, and the outer diameter is Φ34mm. One end of the rotating shaft 33 is fixed with a special magnetic field 31, and the programmable magneto-sensitive integrated chip 29 is installed on a position corresponding to the signal processing circuit board 30 of the programmable magneto-sensitive integrated chip with a diameter of Φ22 mm. It is concentrically mounted on the end cap 32 of the sensor 18 at a selected value interval of 0.1-20 mm. 18 shaft ends of the plane rotation angle sensor and the 7 shaft ends of the non-rotating central shaft of the cloud platform are additionally installed with a gear ratio 1: 1, and a synchronous gear 20,21 whose modulus is 1. When the driving motor makes the pan-tilt r...

Embodiment 2

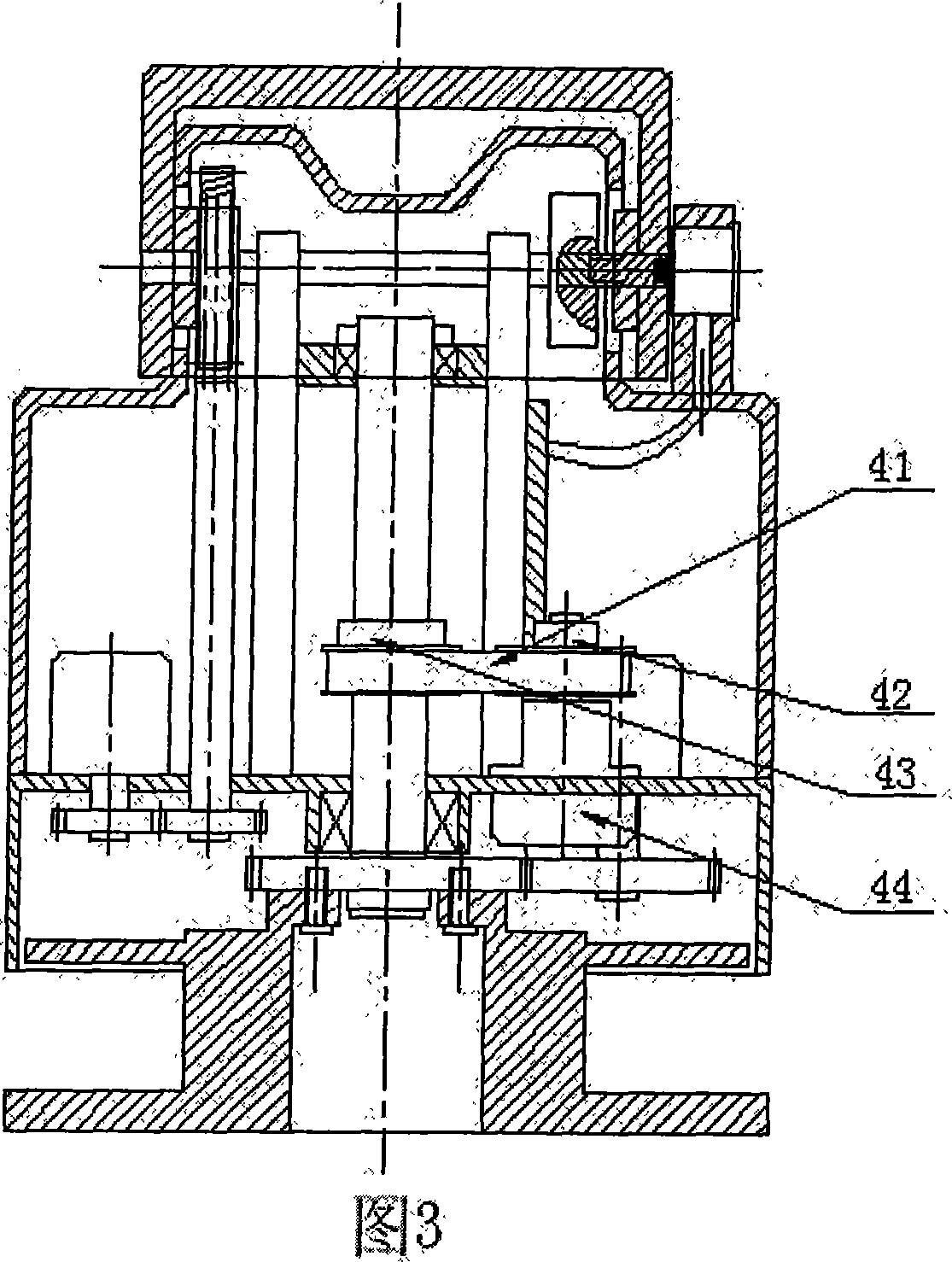

[0033] Use the method of synchronous pulley to measure the plane rotation angle of the pan-tilt, as shown in Figure 3. The synchronous pulley type plane rotation angle sensor 44 is shown in FIG. 4 . A pair of synchronous belt pulleys 42,43 with convex and concave teeth having the same outer diameter are respectively fixed on one end of the plane rotation angle sensor 44 rotating shaft 34 on the rotating lower end cover 2 of the cloud platform, corresponding to the position of the same height as the stationary rotating shaft 7 of the platform. The synchronous wheels 42 and 43 are tightened by the synchronous belt 41 to transmit the pan-tilt plane rotation. The rotating shaft 34 is fixed on the end cover 38 in the plane angle sensor 44 by two bearings 35 and 36 . The other end of the rotating shaft 34 is equipped with a special magnetic field 37, and the magnetic encoder type magnetic sensitive integrated chip 39 is installed on the position corresponding to the signal processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com