Tube made of a profile rolled metal product and method of producing the same

一种管子、产品的技术,应用在制造工具、金属轧制、金属轧制等方向,能够解决空调机组工作温度和压力提高、钎焊连接不是非常坚固等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

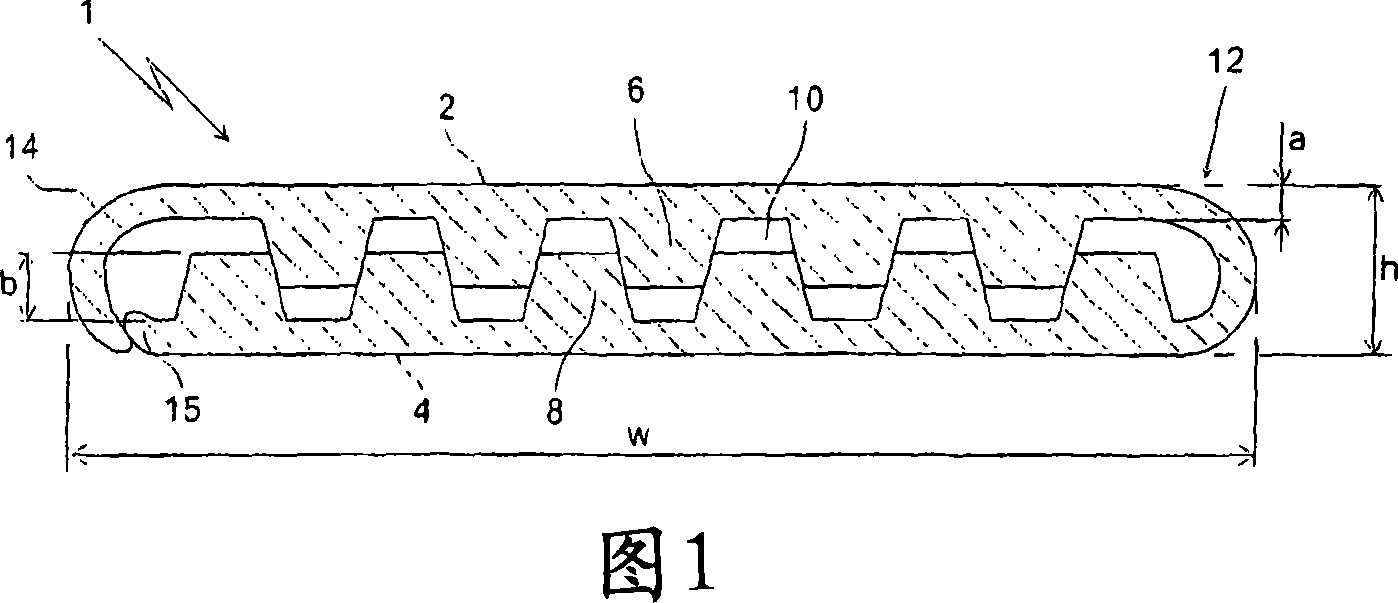

[0046] A schematic cross-sectional view of a refrigerant tube according to a first embodiment of the present invention is shown in FIG. 1 . The tube is generally flat and has a width w of up to 100 mm, typically about 15 to 50 mm, and a height h of up to 10 mm, typically about 0.5 to 5 mm. Prior art tubes made of non-profiled aluminum sheet have a wall thickness of 0.25 to 0.4 mm, but tubes with reinforced walls according to the invention can have thinner walls while maintaining the same stability and compressive strength , for example a=0.1 to 0.3 mm, preferably 0.15 to 0.25 mm.

[0047] The tube is made of an upper wall 2 and a lower wall 4 formed by longitudinally folding a rolled sheet metal like a hairpin. Creases are referenced at 12. On the other side, the upper and lower walls are held together by a flange 14 which, in this example, terminates around a step 15 on the lower wall, thereby creating a gap between the upper and lower walls relative to each other. Mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com