Ellipsoidal ring gear hob

A technology of internal gears and ellipsoids, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., and can solve problems such as large hob diameters and unmanufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

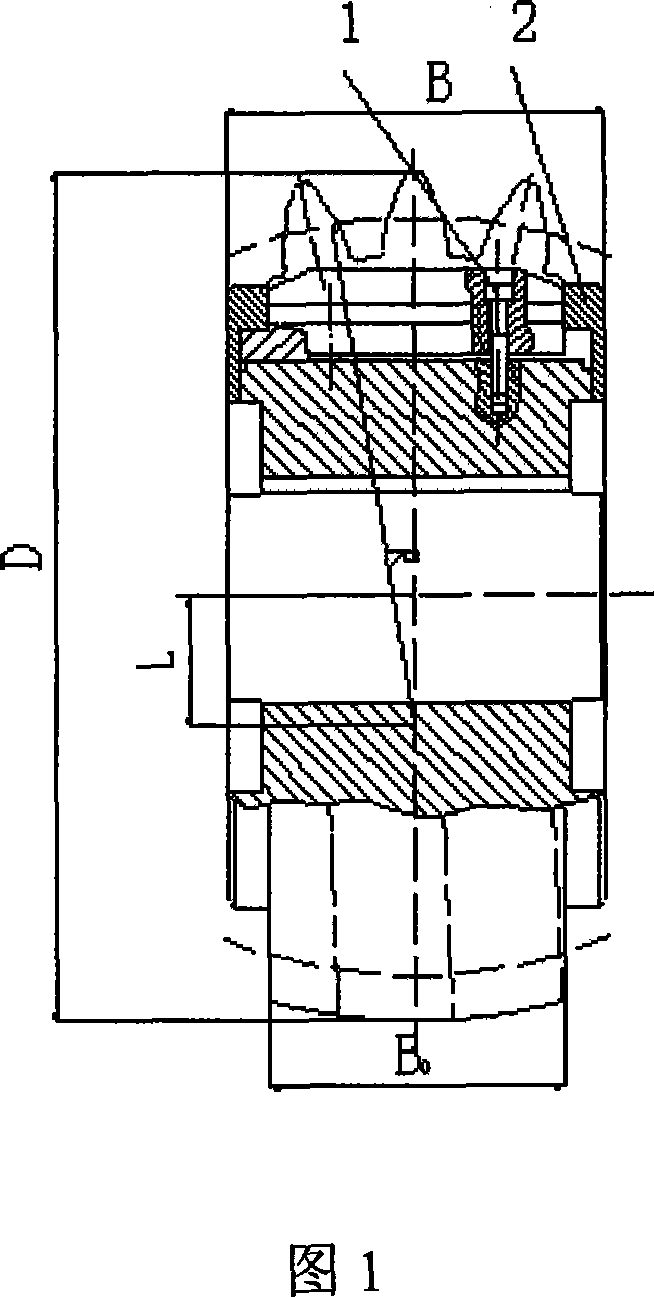

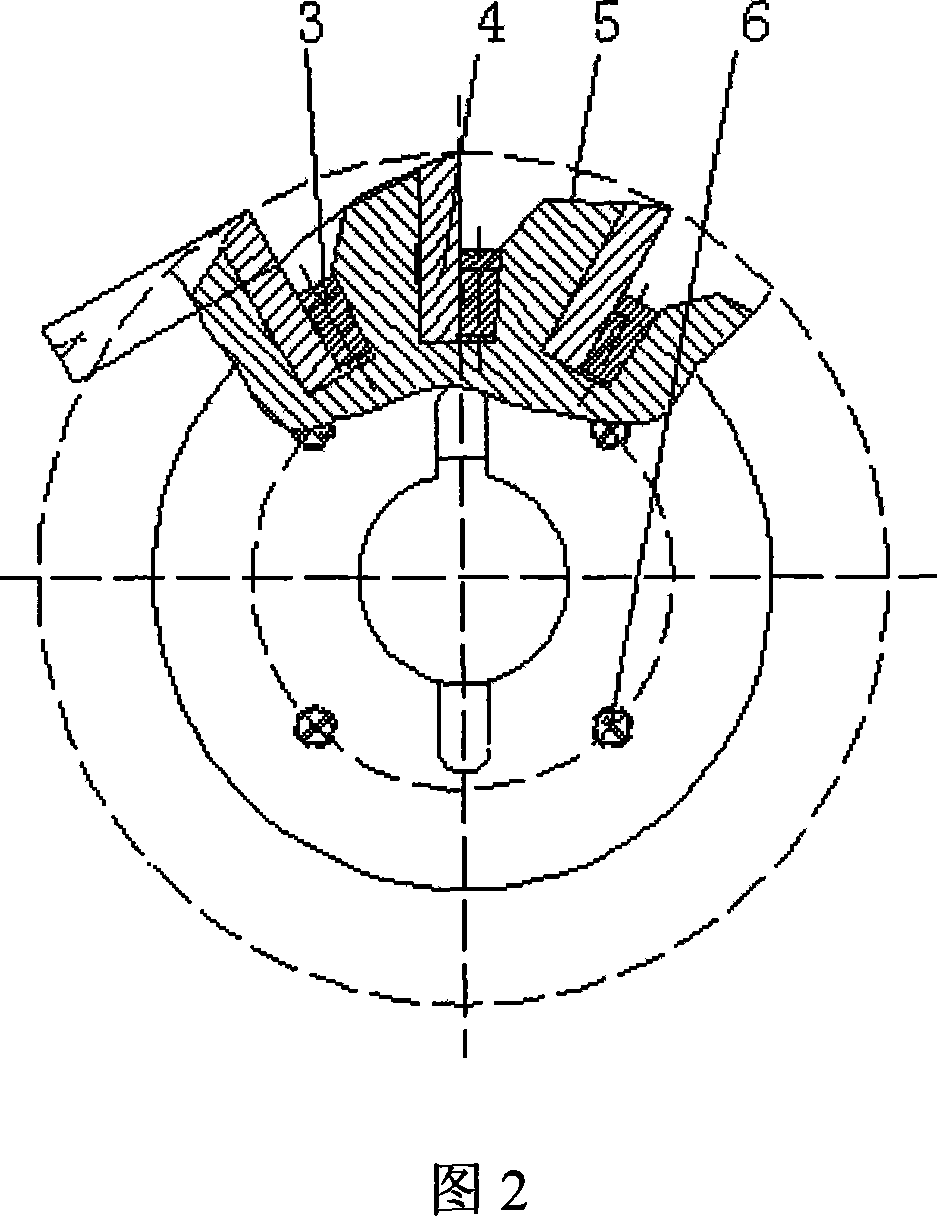

[0013] The ellipsoidal hob shown in Fig. 1 and Fig. 2 is an inlay structure, which consists of a wedge screw 1, a hoop 2, a clamping wedge 3, a toothed blade 4, a cutter body 5, and a hoop screw 6. , the three cutter teeth in each row are made into one body, the axial profile of the elliptical internal gear hob is distributed on a circle with a pitch circle radius R according to the normal direction, it is a part of a gear, and this gear is also It is called an imaginary gear of the ellipsoidal internal gear hob, and the center of the imaginary gear is not on the axis line of the ellipsoidal internal gear hob. It is a gear with a larger radius and more teeth than the imaginary gear of the spherical hob, or when the radii R of the imaginary gears of the ellipsoidal hob and the spherical hob are the same, the outer radius of the ellipsoidal hob is larger than that of the spherical hob. The radius of the outer circle of the hob should be smaller by an L value.

[0014] When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com