Biological extraction process of glycyrrhizic acid

A bio-extraction and glycyrrhizic acid technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of active ingredient dissolution and low yield, corrosion, isomerization, etc., to reduce equipment and Reagent costs, saving licorice resources, and the effect of eliminating quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

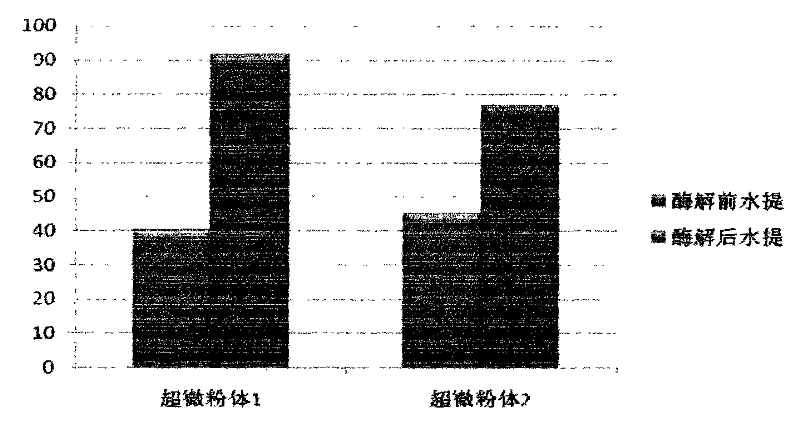

[0052] Embodiment 1: the preparation of glycyrrhizic acid intermediate raw material

[0053] Purpose: To obtain feed grade, food grade and pharmaceutical grade intermediate raw materials.

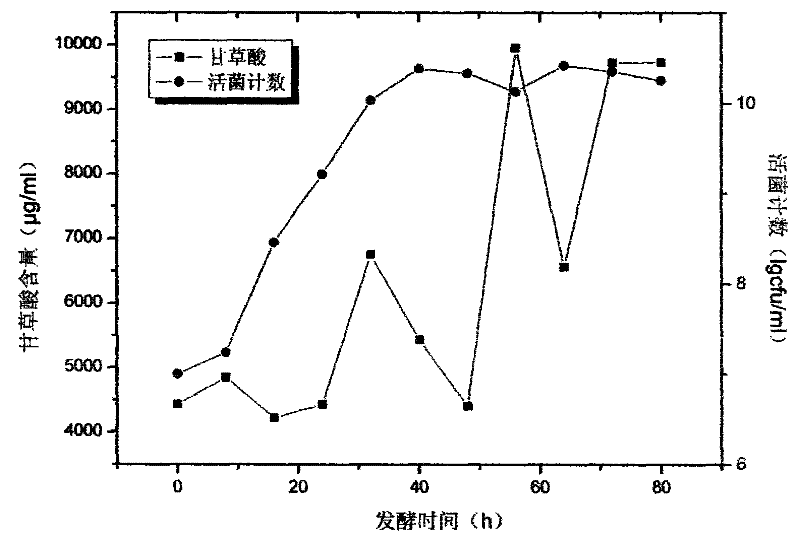

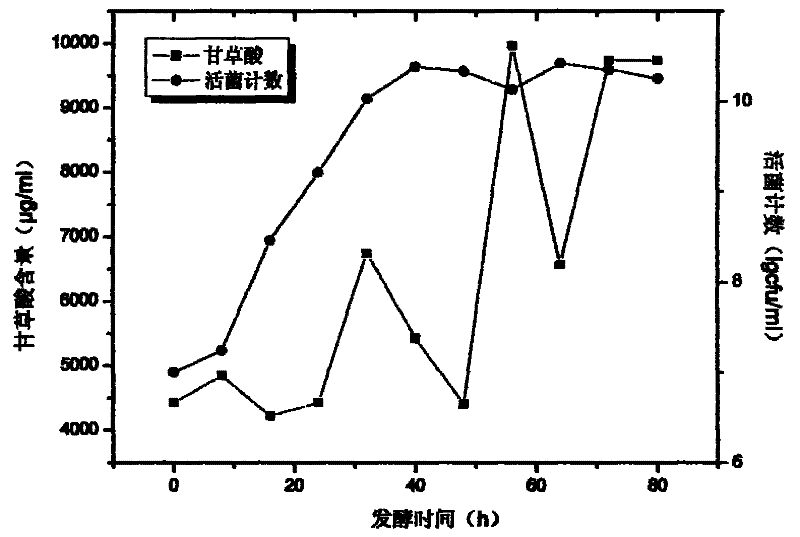

[0054] Common technical route: washing licorice, removing impurities, drying, slicing, mechanically crushing to an average particle size of 100-150 μm, and then jet-pulverizing to an average particle size of 5-25 μm; The crude enzyme solution is subjected to co-enzymolysis reaction, decocted and extracted with pure water, and the filtrate is graded and filtered and concentrated into a fermentation stock solution; Lactobacillus performs anaerobic liquid submerged fermentation on the fermentation stock solution, and after the fermentation is terminated, the bacteria are separated and the enzyme is inactivated, and the fermentation product is passed through hot ethanol Extraction, activated carbon decolorization and filtration to obtain crude glycyrrhizic acid, silica gel column chromatography...

Embodiment 2

[0058] Example 2: Preparation of Glycyrrhizic Acid Oral Capsules

[0059] Objective: To obtain oral preparations of glycyrrhizic acid.

[0060] Common technical route: after the licorice decoction pieces are purified, they are mechanically crushed to an average particle size of 100-150 μm, and then air-jet crushed to an average particle size of 5-25 μm, and co-enzymolyzed with lignin-degrading enzyme system and cellulose-degrading enzyme system crude enzyme solution for 48 hours. Decoction with pure water, graded filtration and concentration of the filtrate into a fermentation stock solution, anaerobic liquid submerged fermentation of the licorice fermentation stock solution by Lactobacillus, separation of the bacteria after termination of fermentation and inactivation of enzymes, hot ethanol extraction of the fermented product, decolorization of activated carbon and filtration to obtain glycyrrhizic acid The crude product was subjected to silica gel column chromatography and ...

Embodiment 3

[0062] Embodiment 3: preparation of monoammonium glycyrrhizinate injection

[0063] Objective: To obtain glycyrrhizic acid injection preparations.

[0064]Common technical route: after the licorice decoction pieces are purified, they are mechanically crushed to an average particle size of 100-150 μm, and then air-jet crushed to an average particle size of 5-25 μm, and co-enzymolyzed with lignin-degrading enzyme system and cellulose-degrading enzyme system crude enzyme solution for 48 hours. Decoction with pure water, graded filtration and concentration of the filtrate into a fermentation stock solution, anaerobic liquid submerged fermentation of the licorice fermentation stock solution by Lactobacillus, separation of the bacteria and inactivation of enzymes after termination of fermentation, hot ethanol extraction of the fermented product, reflux of activated carbon for decolorization, and filtration to obtain licorice acid crude filtrate.

[0065] Product preparation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com