Flat-plate antenna and packaging device and bushing device

A technology for packaging devices and antennas, which is applied to antennas, antenna arrays, antenna components and other directions, can solve the problems of poor production consistency, troublesome processes, and low production efficiency of FRP radomes, and achieves simple and fast assembly processes and overall manufacturing. The effect of cost reduction, high electrical performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

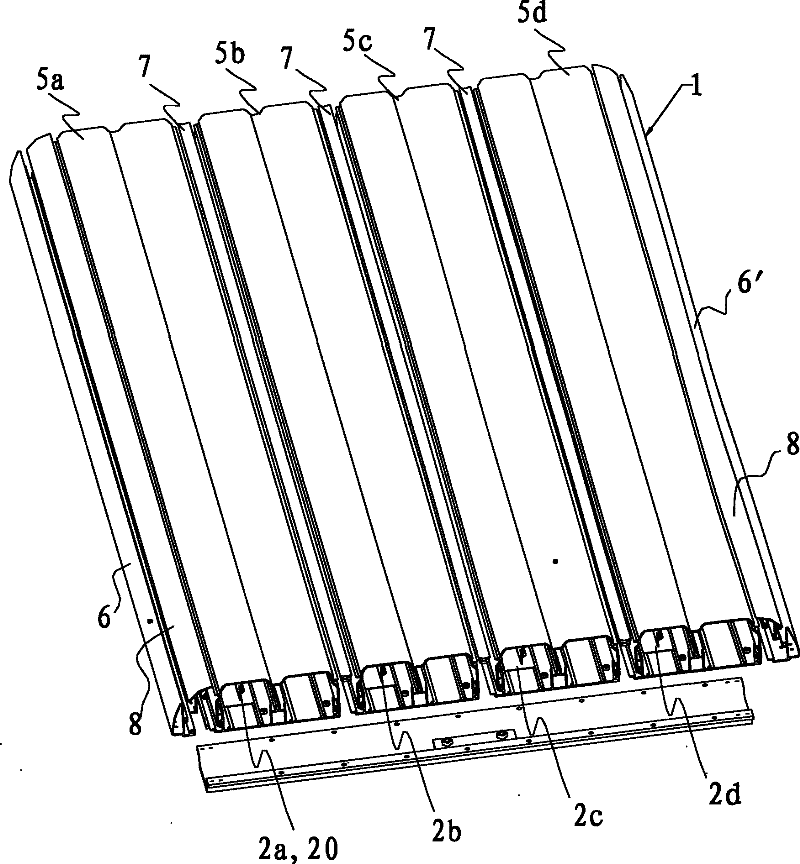

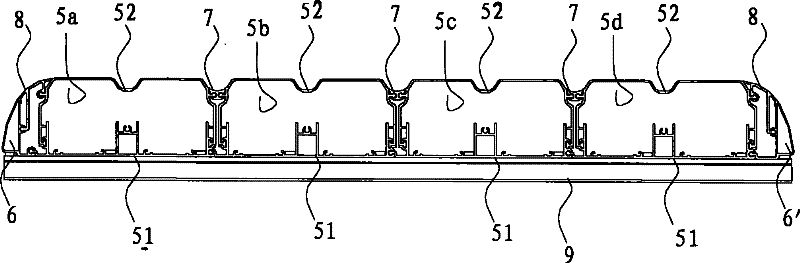

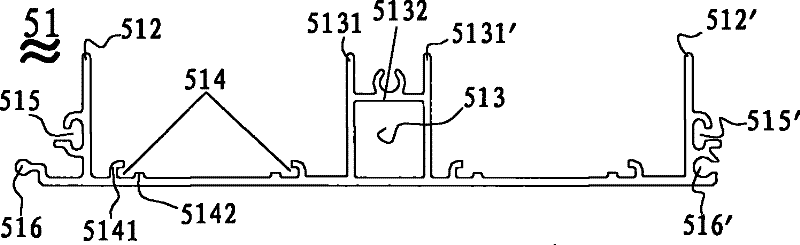

[0043] see figure 1 and figure 2 , the panel antenna of the present invention includes an antenna package device 1, radiation oscillator columns 2a-2d, a power division network (not shown), a calibration network (not shown) and a shielding box (not shown), and the antenna package device 1 is used for An installation platform is provided for the entire antenna. The radiation oscillator rows 2a-2d are formed by a single row of multiple radiation oscillators 20 arranged along the same longitudinal direction, and the radiation oscillators 20 of the same radiation oscillator row 2a-2d pass through The power dividing network (not shown) realizes parallel feeding, and multiple radiating oscillator columns 2a-2d form an antenna array. In the antenna array, the power dividing network (not shown) of each radiating oscillator column 2a-2d and the calibration network (not shown) are electrically connected, so that the signal calibration of the power dividing network (not shown) can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com