Method and batching for precise control over apparent density of ceramic powder

A technology of ceramic powder and bulk density, which is applied in the field of ceramics, can solve the problem that it is difficult to obtain powder with particle size distribution, and achieve the effect of stabilizing the weight of the green body and improving the consistency of electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

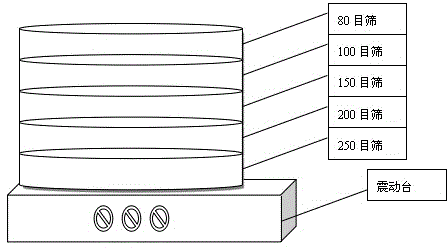

[0020] Embodiment 1: Vibrating 500Kg of zinc oxide ceramic powder through a set of sieves composed of 80 mesh, 100 mesh, 150 mesh, 200 mesh and 250 mesh from top to bottom, see figure 2 , mixed according to the ratio in Table 1.

[0021] Granularity range Below 250 mesh 250~200 mesh 200~150 mesh 150~100 mesh 100~80 mesh 80 mesh or more add ratio 6 parts by weight 8 parts by weight 15 parts by weight 55 parts by weight 12 parts by weight 4 parts by weight

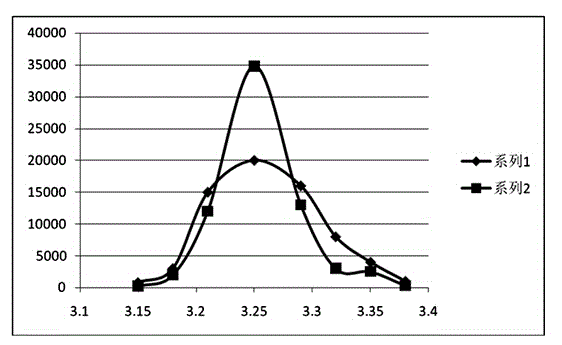

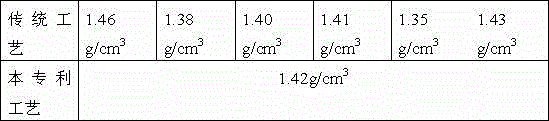

[0022] Table 2 lists the bulk density comparison of the powder treated by this patent and the five batches of powder produced by the traditional process:

[0023]

[0024] In Figure 2, series 1 is the powder processed by this patent, and series 2 is the powder without this patent. The two powders were dry pressed under the same conditions, and the target density was 3.25g / cm3. The figure shows the distribution of the density of the molded green sheets in the range of 3.10~3.4g / ...

Embodiment 2

[0026] Embodiment 2: Vibrating 500Kg of zinc oxide ceramic powder through a set of sieves composed of 80 mesh, 100 mesh, 150 mesh, 200 mesh and 250 mesh from top to bottom, see figure 2 , mixed according to the ratio in Table 3.

[0027] Granularity range Below 250 mesh 250~200 mesh 200~150 mesh 150~100 mesh 100~80 mesh 80 mesh or more add ratio 2 parts by weight 10 parts by weight 13 parts by weight 57 parts by weight 40 parts by weight 6 parts by weight

Embodiment 3

[0029] Vibrate 500Kg of zinc oxide ceramic powder through a set of sieves consisting of 80 mesh, 100 mesh, 150 mesh, 200 mesh and 250 mesh from top to bottom, see figure 2 , mixed according to the ratio in Table 4.

[0030] Granularity range Below 250 mesh 250~200 mesh 200~150 mesh 150~100 mesh 100~80 mesh 80 mesh or more add ratio 8 parts by weight 6 parts by weight 17 parts by weight 53 parts by weight 14 parts by weight 2 parts by weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com