Method for preparing hydrophilic polyethersulfone membrane

A polyethersulfone and hydrophilic technology, which is applied in the field of preparing hydrophilic polyethersulfone membranes, can solve problems such as process consistency and membrane quality not always meeting needs, changing membrane hydrophilicity, and damaging membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1 illustrates a batch approach to a process disclosed in the present invention.

[0080] The first step includes: preparing a hydrophobic PES membrane. First, use the following formula to cast a film on a glass plate:

[0081] PES polymer (Radel polymer from Solvay) - 14%;

[0082] 1-methyl-2-pyrrolidone (solvent) -21%;

[0083] Polyethylene glycol 400 (pore former) - 65%.

[0084] The cast film was then air quenched for about 25 minutes in a humidity chamber at a temperature of about 23° C. and an air humidity of about 65% to about 68%. The membrane thus quenched was then washed with DI water for about 30 minutes and then dried at about 80°C for about 15 minutes.

[0085] First, the hydrophobic PES film obtained as described above was used in this example, and also in other examples (the following examples 2-5).

[0086] Once the hydrophobic PES membrane is obtained, it is hydrophilized as follows:

[0087] Hydrophobic PES membrane samples (approximately ...

Embodiment 2

[0093] Example 2 shows the membrane hydrophilization process using another oxidizing agent (sodium hypochlorite).

[0094] Example 2

[0095] Hydrophobic PES membrane samples (8 cm x 40 cm) were pre-wet in IPA, washed with DI water and soaked in about 12% aqueous sodium hypochlorite for about 3 minutes. The membrane was then removed from the solution and wound into a roll with a diameter of approximately 3 cm. The rolled film was dipped again in a 12% aqueous solution of sodium hypochlorite, and the temperature of the solution was raised to about 97°C. The membrane was kept in the solution at the above temperature for about 1 hour. The membrane roll was then removed from the solution, the membrane was unrolled, washed with DI water for about 30 minutes, and dried at about 70°C for about 30 minutes. The resulting membrane is hydrophilic: it wets instantaneously in water.

[0096] Therefore, the process of hydrophilization of PES membranes according to the present disclosure...

Embodiment 3

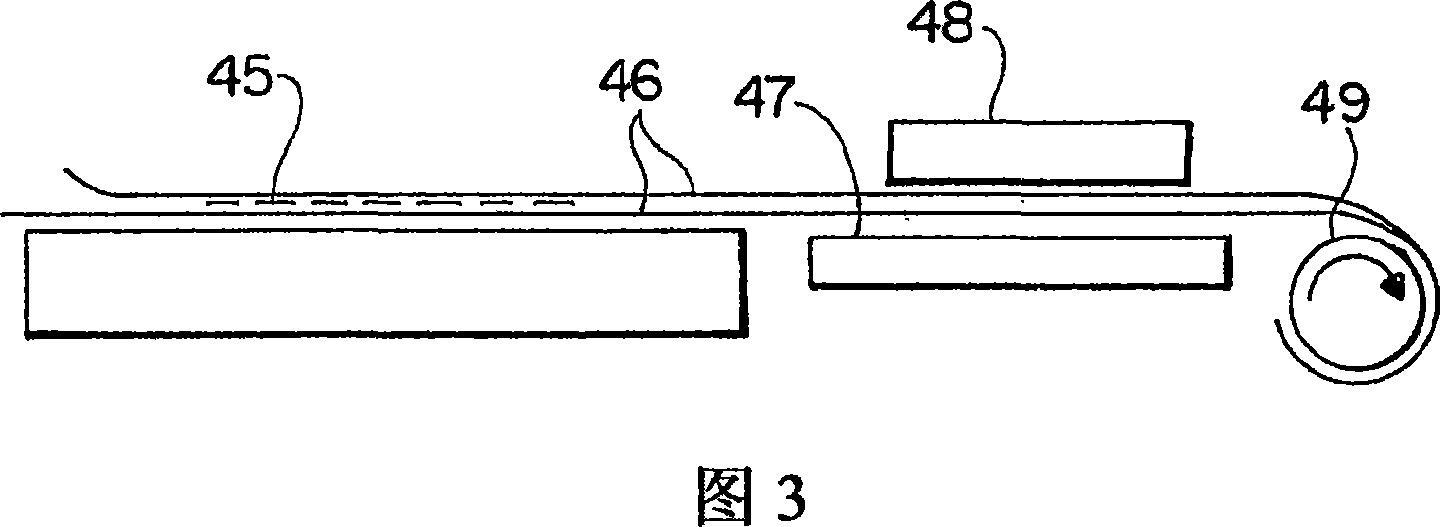

[0103] Hydrophobic PES membrane samples (about 8 cm x about 24 cm) were pre-wet with IPA, washed with DI water for about 5 minutes and soaked in about 3% APS solution for about 2 minutes. Then, the samples were processed in the apparatus shown in FIG. 3 . The film sample 45 after soaking in the APS solution was sandwiched between two Mylar 46 strips. One end of the interlayer is attached to a roller 49 which pulls the interlayer along the surface of the hot plate 47 at a speed of about 30 cm / min. The hot plate has a temperature adjustment capability of + / - 1°C and is preheated to about 102°C. A piece of sponge 48 was placed on the sandwich surface to press the sandwich evenly against the hot plate and prevent the film from cooling. The hot plate length was about 60 cm, and the sandwich was moved at a speed (about 30 cm / min) such that the film was heated on the hot plate for about 2 minutes. After heating, the membrane was removed from the interlayer, washed in water for abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com