Apparatus and method for inspecting edge defect and discoloration of glass substrate

A glass substrate, edge defect technology, applied in the field of edge defect and discoloration devices, capable of solving problems such as separation, variation of determination results, inability to perform accurate inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

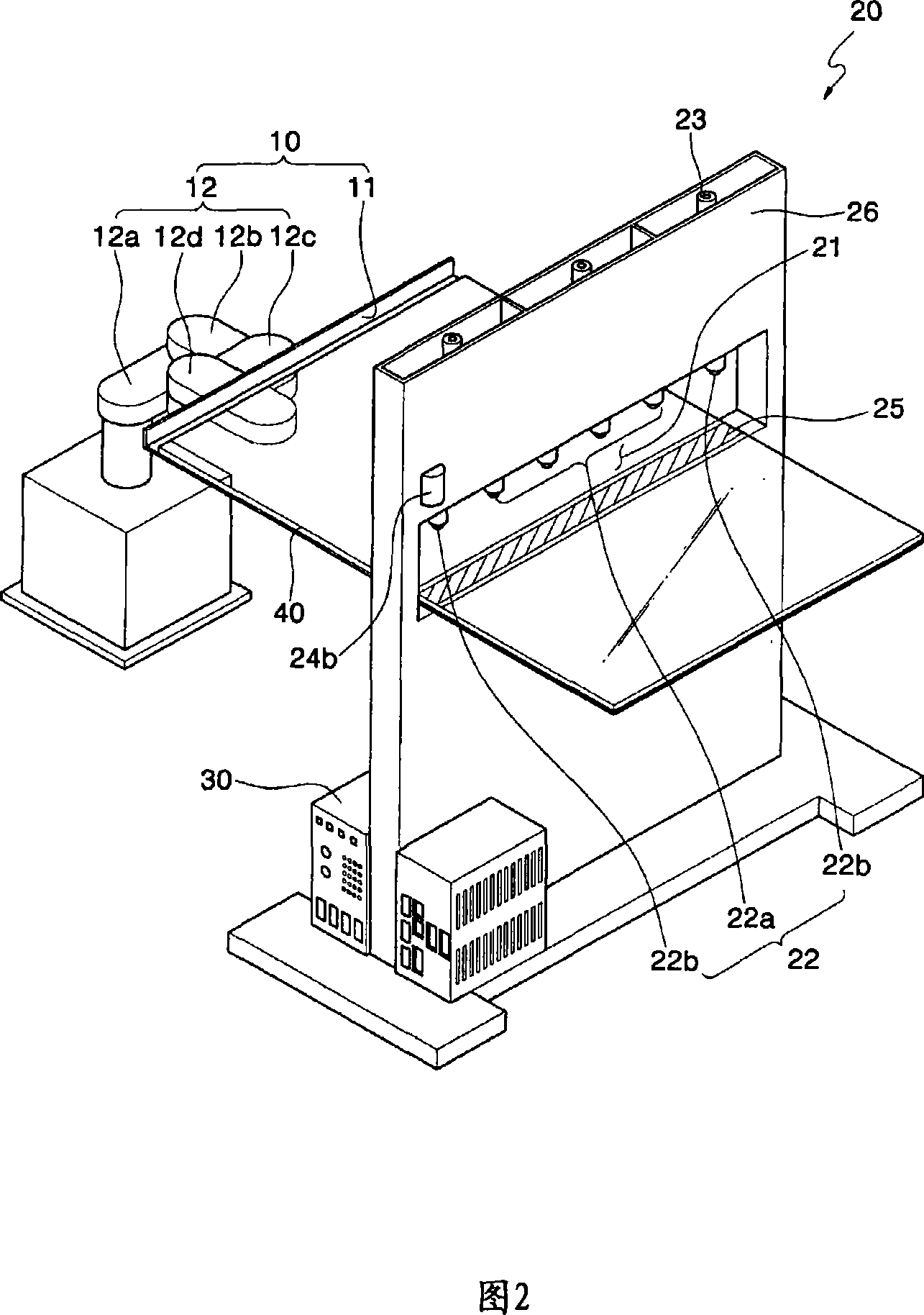

[0037] Now, embodiments of the present invention will be described in detail, examples of which are shown in the accompanying drawings.

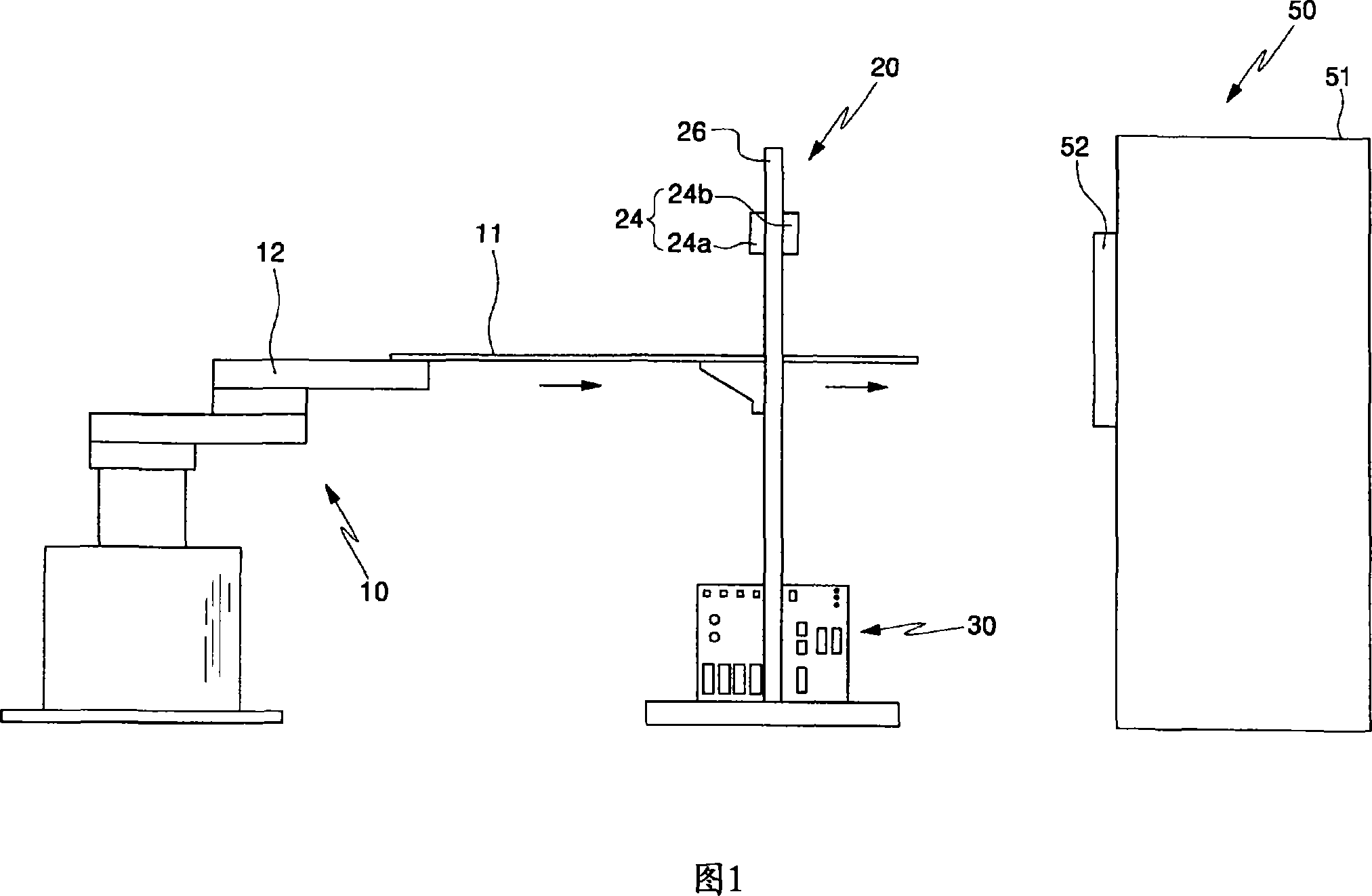

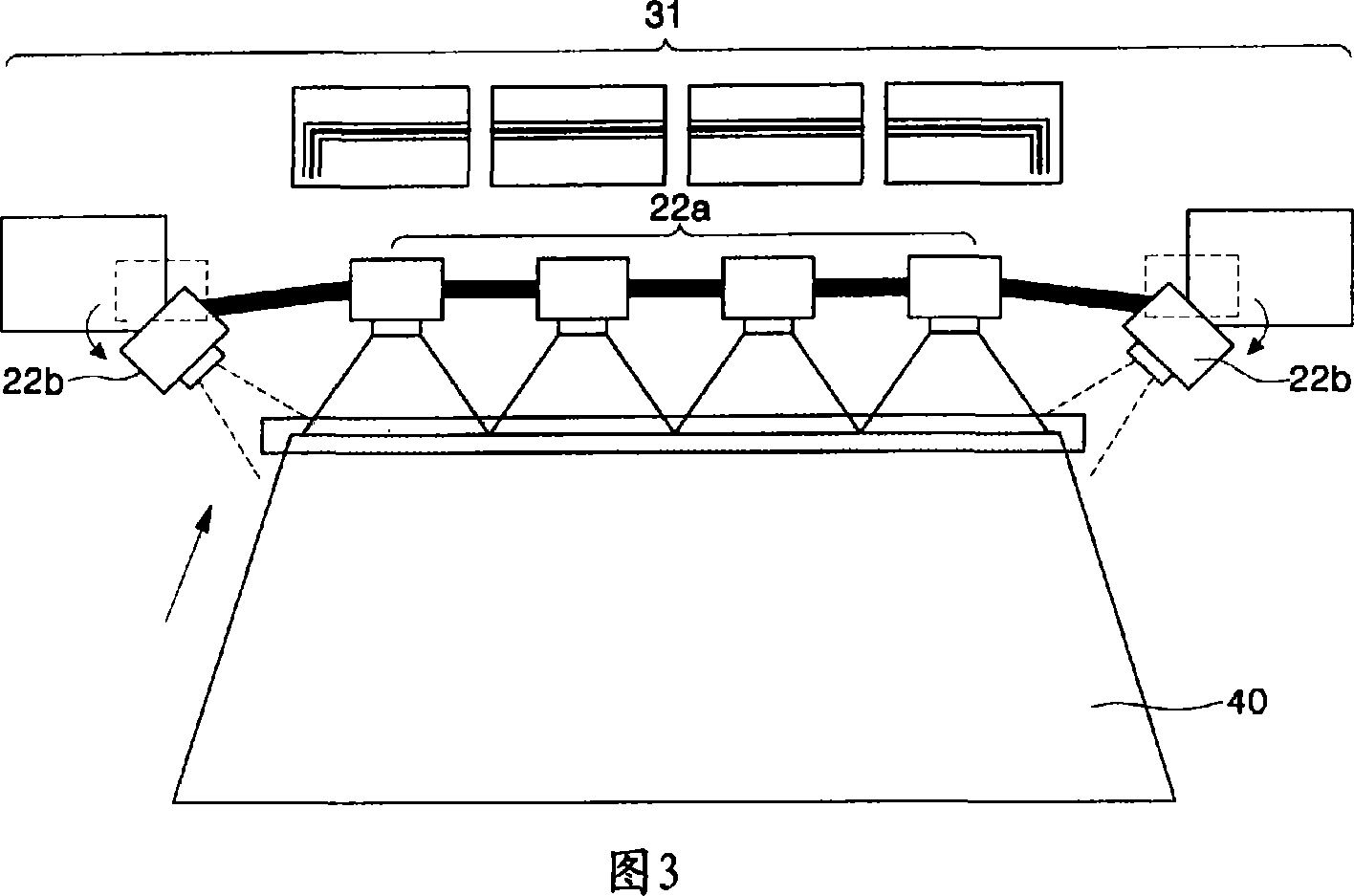

[0038] 1 is a side view of an edge defect and discoloration inspection device according to the present invention, which is installed in front of a gate valve (gate valve) of a deposition or etching device for manufacturing a thin film transistor liquid crystal display, and FIG. Perspective view of the edge defect and discoloration inspection device of the embodiment.

[0039] 1 and 2, the edge defect and discoloration inspection device is selectively installed before the inlet gate valve 52 or after the outlet gate valve (not shown) of the processing equipment 50 using plasma Deposition, etching and sputtering processes are performed to use plasma to manufacture thin film transistor liquid crystal displays.

[0040] The reason for this is to inspect the edge defects and discoloration of the glass substrate 40 before the glass substrate 40 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com