Composite inhibitor for inhibiting arsenic ore floatation

A compound inhibitor and mineral flotation technology, which is applied in the field of ore dressing inhibitors, can solve problems such as excessive arsenic content in concentrates, achieve the effects of inhibiting arsenopyrite, increasing income, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

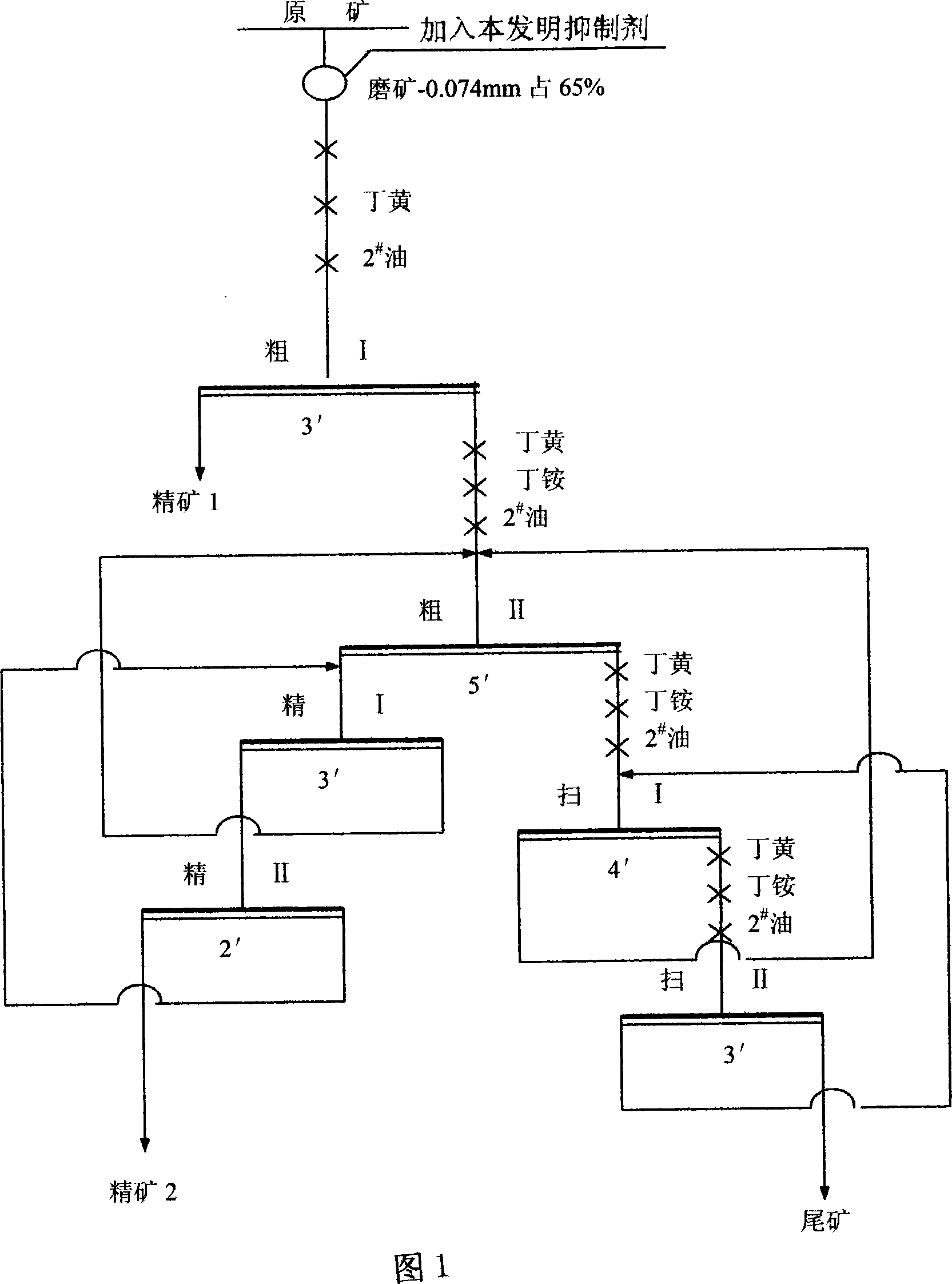

Method used

Image

Examples

Embodiment 1

[0039] The composite inhibitor of the present invention takes raw materials according to the following weight ratio, and the total consumption relative to the raw ore is 9.0kg / t.

[0040] CaO 76.1%

[0041] Na 2 SO 3 ·7H 2 O 21.7%

[0042] Sodium Humate 2.2%.

[0043] Closed circuit test results of copper arsenic separation flotation:

[0044]

Embodiment 2

[0046] The composite inhibitor of the present invention takes raw materials according to the following weight ratio, and the total consumption relative to the raw ore is 8.0kg / t.

[0047] CaO 86.4%

[0048] Na 2 SO 3 ·7H 2 O 12.3%

[0049] Sodium Humate 1.3%.

[0050] Closed circuit test results of copper arsenic separation flotation:

[0051]

Embodiment 3

[0053] The composite inhibitor of the present invention takes raw materials according to the following weight ratio, and the total consumption relative to the raw ore is 7.0kg / t.

[0054] CaO 89%

[0055] Na 2 SO 3 ·7H 2 O 9%

[0056] Sodium Humate 2%.

[0057] Closed circuit test results of copper arsenic separation flotation:

[0058]

[0059] Above embodiment results show, adopt the present invention as the composite inhibitor of copper, arsenic separation, have obtained the priceable copper (below 3% containing arsenic) of recovery rate 53.10% in concentrate product; Concentrate 1 and concentrate 2 The grade of Zhongyin is above 3kg / t, and can be sold at normal prices. With the production capacity of 300t / d, the annual profit can be increased by more than 5 million yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com