Cooling tower water-steam recovery method

A water vapor recovery and cooling tower technology, applied in separation methods, water shower coolers, chemical instruments and methods, etc., can solve the problems of overflowing cooling towers, total area limitation of condensation plates, loss, etc., to achieve low overall cost and implement equipment. Low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

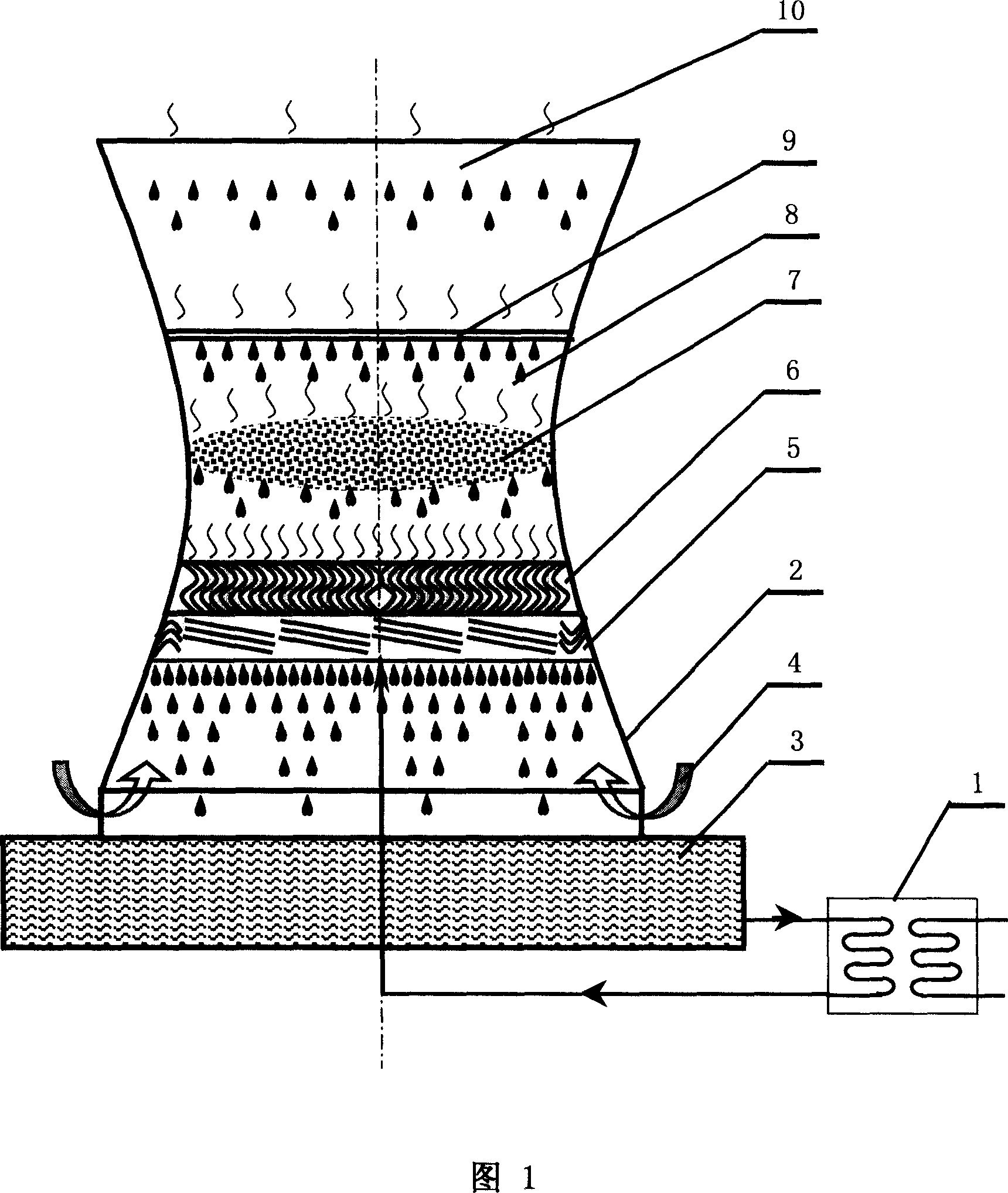

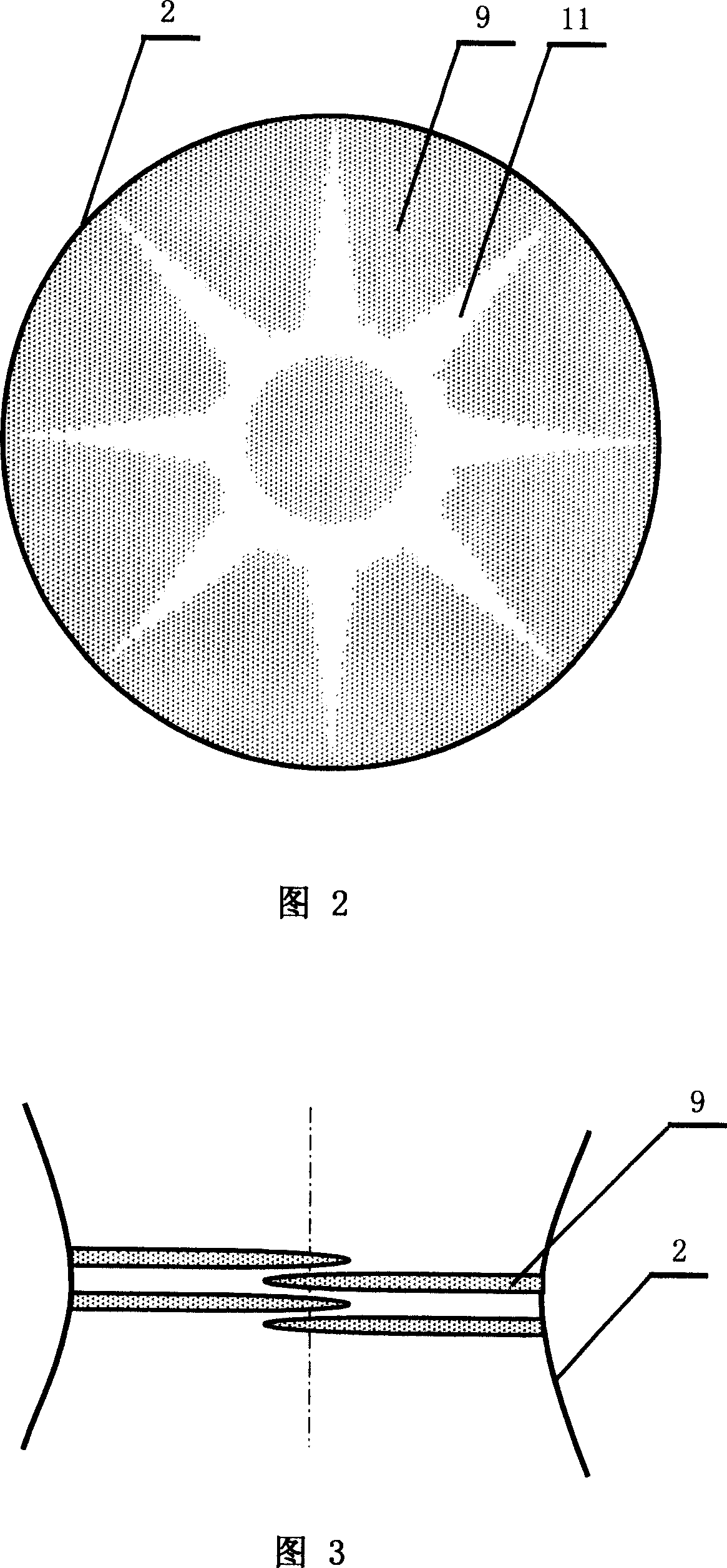

[0042] Referring to Fig. 1 , in the condensing generator set used in thermal power generation, the cooling water whose temperature rises after heat exchange in the condenser 1 enters the cooling tower 2 . Under the action of the self-extraction force of the cooling tower 2, the external cold air 4 enters the cooling tower 2 from the air inlet at the bottom of the cooling tower 2 and flows upward. After the cooling water whose temperature has risen is cooled by the external cold air 4 at the spraying device 5, most of it falls back into the reservoir 3, and enters the condenser 1 again for heat exchange. After being cooled by the spraying device 5, a small part of the cooling water will become water vapor and fine water droplets, which rise under the action of the self-extraction force of the cooling tower 2. If steam catcher 6 is arranged in cooling tower 2, then a small part of water vapor and fine water droplets will condense into water and fall to recycle, while most of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com