Method and appliance for treating flocked waste gas

A waste gas and flocking technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of waste gas treatment processes and equipment, the impact of waste gas on the surrounding environment, and residents' production and life, and achieve low operating costs. Stable effect and strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

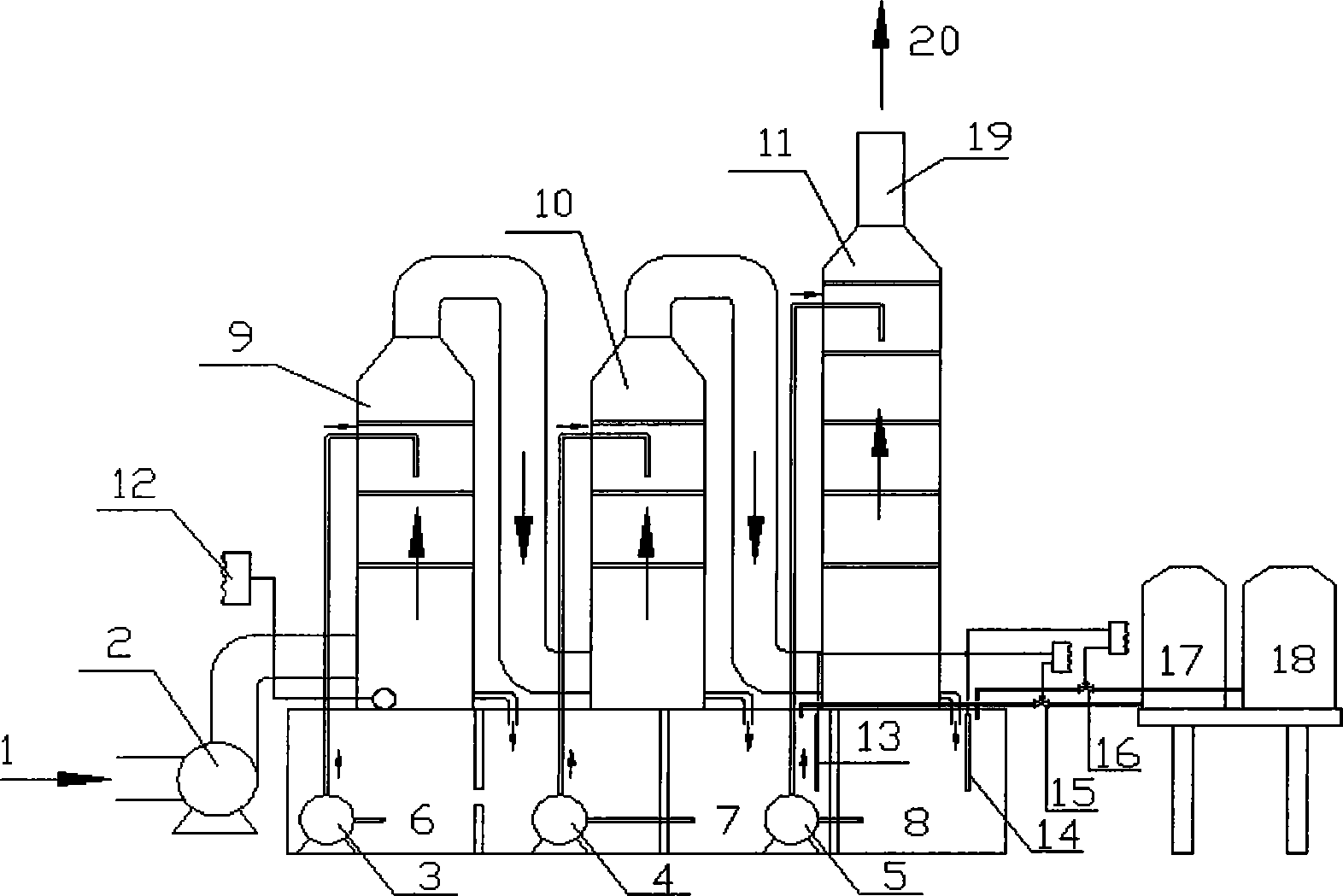

[0021] As shown in the drawings, the present invention includes a centrifugal fan 2, an anti-corrosion thick slurry pump 3, a first anti-corrosion pump 4, a second anti-corrosion pump 5, a circulating water pool 6, a sodium hypochlorite solution pool 7, an lye pool 8, and a water spray tower 9 , oxidation tower 10 and alkali washing tower 11; One end of centrifugal fan 2 is connected to flocking waste gas inlet 1, and the other end of centrifugal fan 2 is connected to the lower end of oxidation tower 10, and the upper end of oxidation tower 10 is connected with the lower end of oxidation tower 10, oxidation The upper end of the tower 10 is connected with the lower end of the alkali washing tower 11, and the upper end of the alkali washing tower 11 is connected to the discharge port 20 through the exhaust pipe 19, and the water spray tower 9, the oxidation tower 10 and the alkali washing tower 11 are circulated with the lower end respectively through pipes. The pool 6, the sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com