Production and use for non-metallic doped nano-TiO

A non-metallic, nanotechnology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

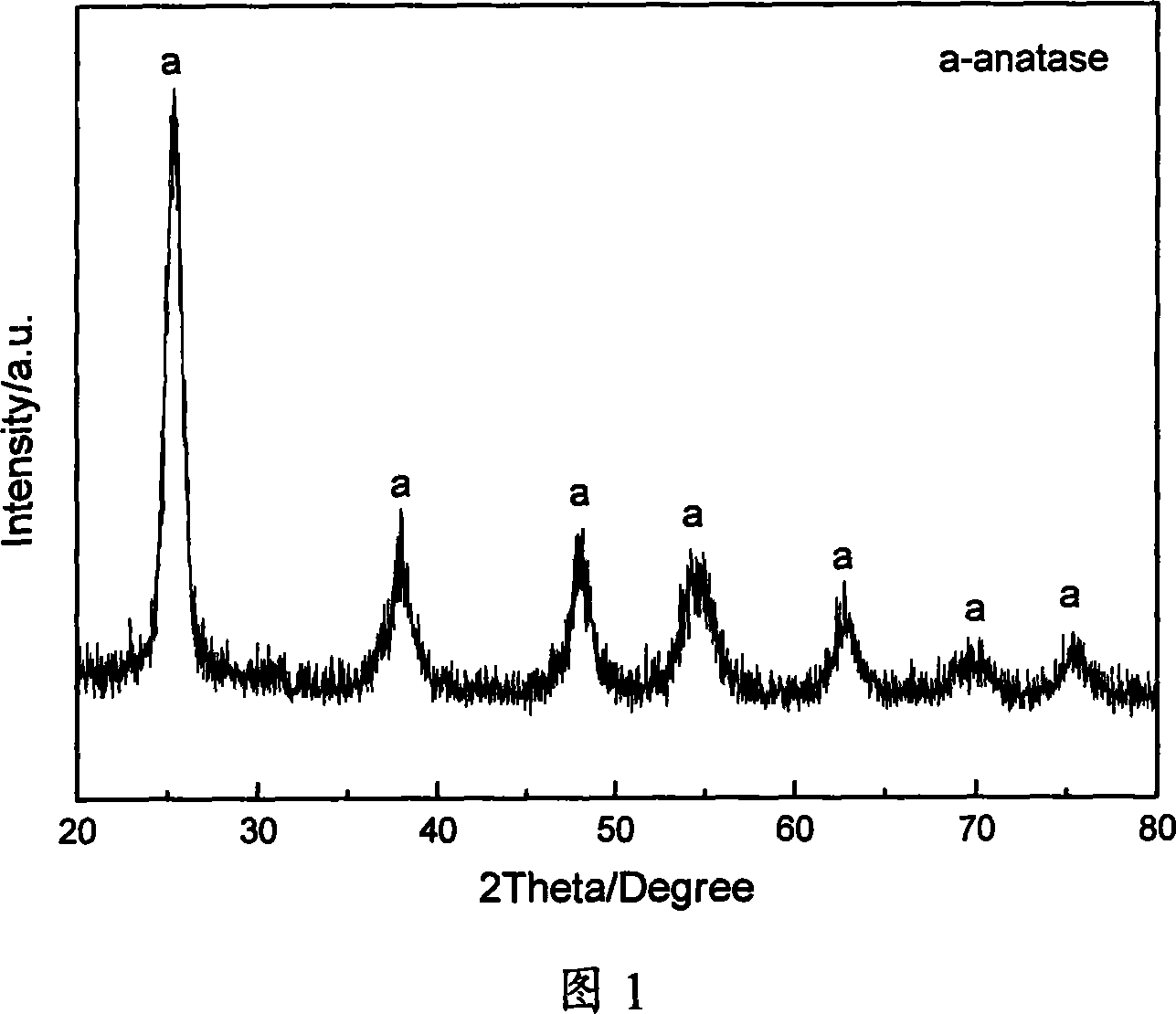

[0023] Hydrothermal preparation conditions: TiN is used as the precursor, the molar concentration is 0.1M, the pH value of the solution is controlled by HCl, the molar concentration is 2M, the hydrothermal temperature is 110°C, the hydrothermal time is 60h, and the filling degree is 50%. After the hydrothermal synthesis reaction, the non-metal doped nano-TiO was obtained by washing, drying and grinding 2 catalyst.

Embodiment 2

[0025] Hydrothermal preparation conditions: TiN is used as the precursor, the molar concentration is 3M, and H 2 SO 4 To control the pH value of the solution, the molar concentration is 0.1M, the hydrothermal temperature is 300°C, the hydrothermal time is 1h, and the filling degree is 30%. After the hydrothermal synthesis reaction, the non-metal doped nano-TiO was obtained by washing, drying and grinding 2 catalyst.

Embodiment 3

[0027] Hydrothermal preparation conditions: TiN is used as the precursor, the molar concentration is 0.5M, CH 3COOH is used to control the pH value of the solution, its molar concentration is 0.5M, the hydrothermal temperature is 200°C, the hydrothermal time is 24h, and the filling degree is 90%. After the hydrothermal synthesis reaction, the non-metal doped nano-TiO was obtained by washing, drying and grinding 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com