Method for estimating engine crank corner and rotation speed

A technology of crankshaft rotation angle and crankshaft rotation speed is applied in the field of estimation of crankshaft rotation angle and rotation speed of engine. source, the effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

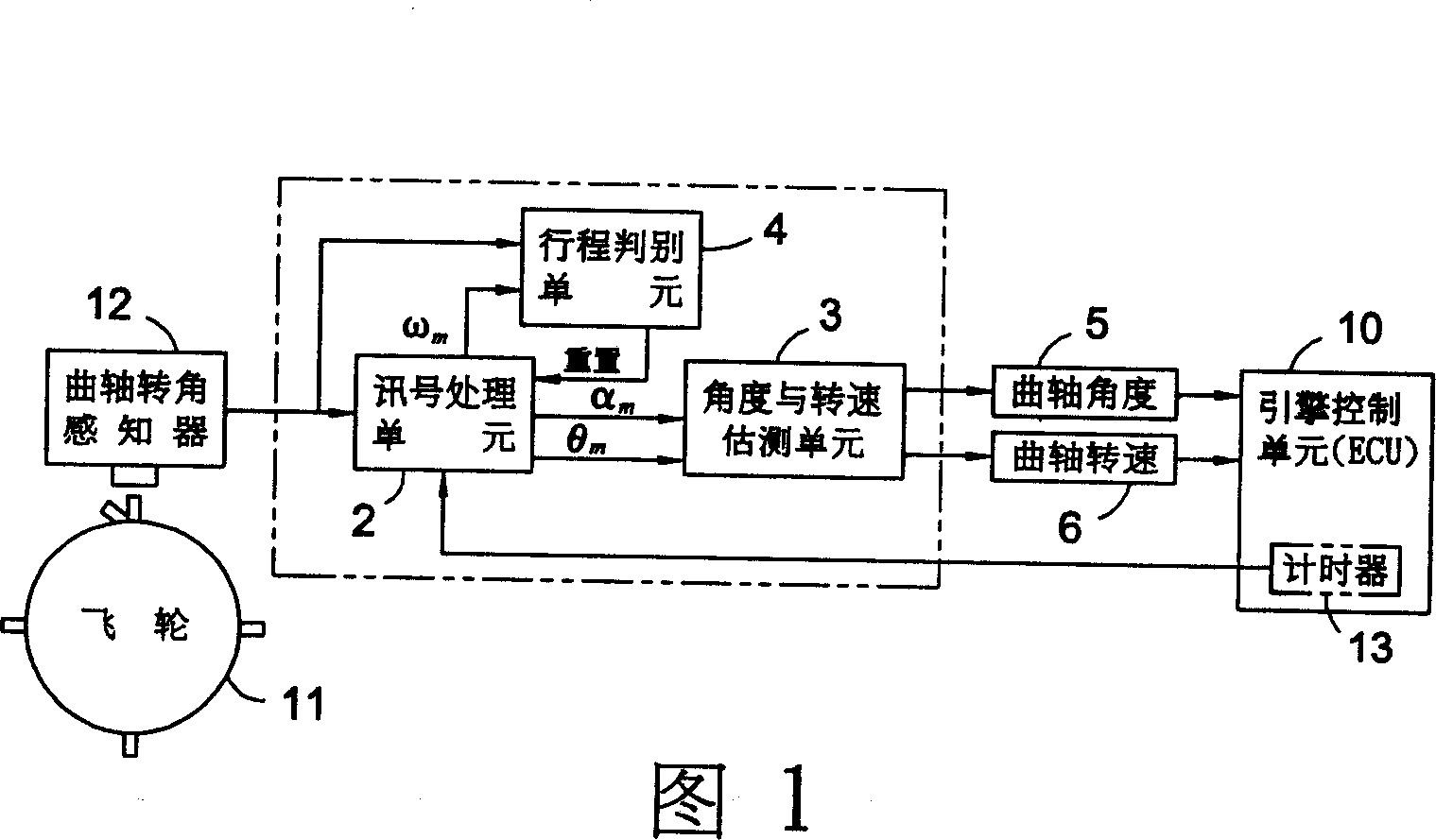

[0028] As shown in Figure 1, it discloses the framework of the method for estimating the crankshaft angle and rotational speed of the engine of the present invention, at least comprising a signal processing unit 2 and another rotational angle and rotational speed estimation unit 3 for estimating the crankshaft angle 5 and Speed 6. In addition, the present invention may also include a stroke judging unit 4 to assist the signal processing unit 2 in processing the crankshaft signal more accurately.

[0029] Above-mentioned estimating method is mainly configured on an engine control unit 10 or its periphery which can utilize crankshaft angle sensor 12 to detect crankshaft tooth signal and have a timer 13 signal output on flywheel 11, and execute the crankshaft estimation engine Rotation angle 5 and crankshaft speed 6, its method is as follows:

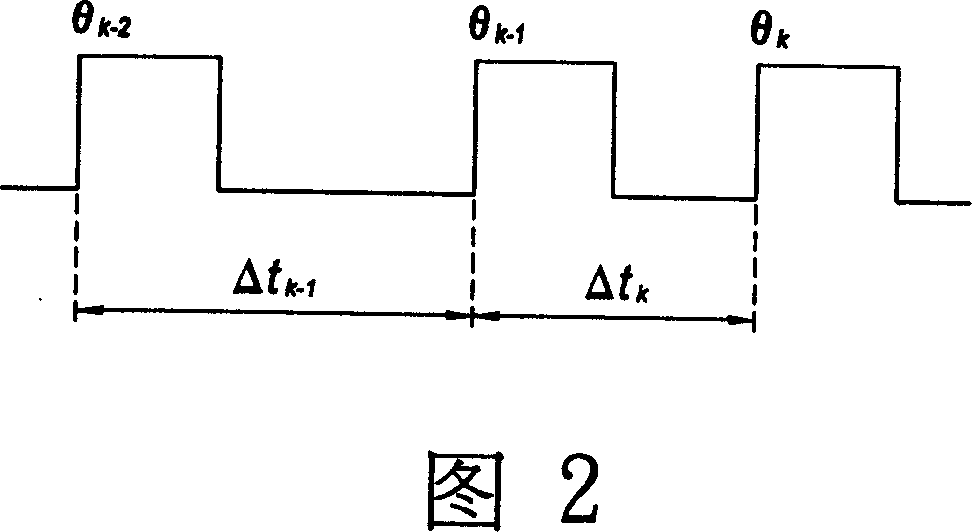

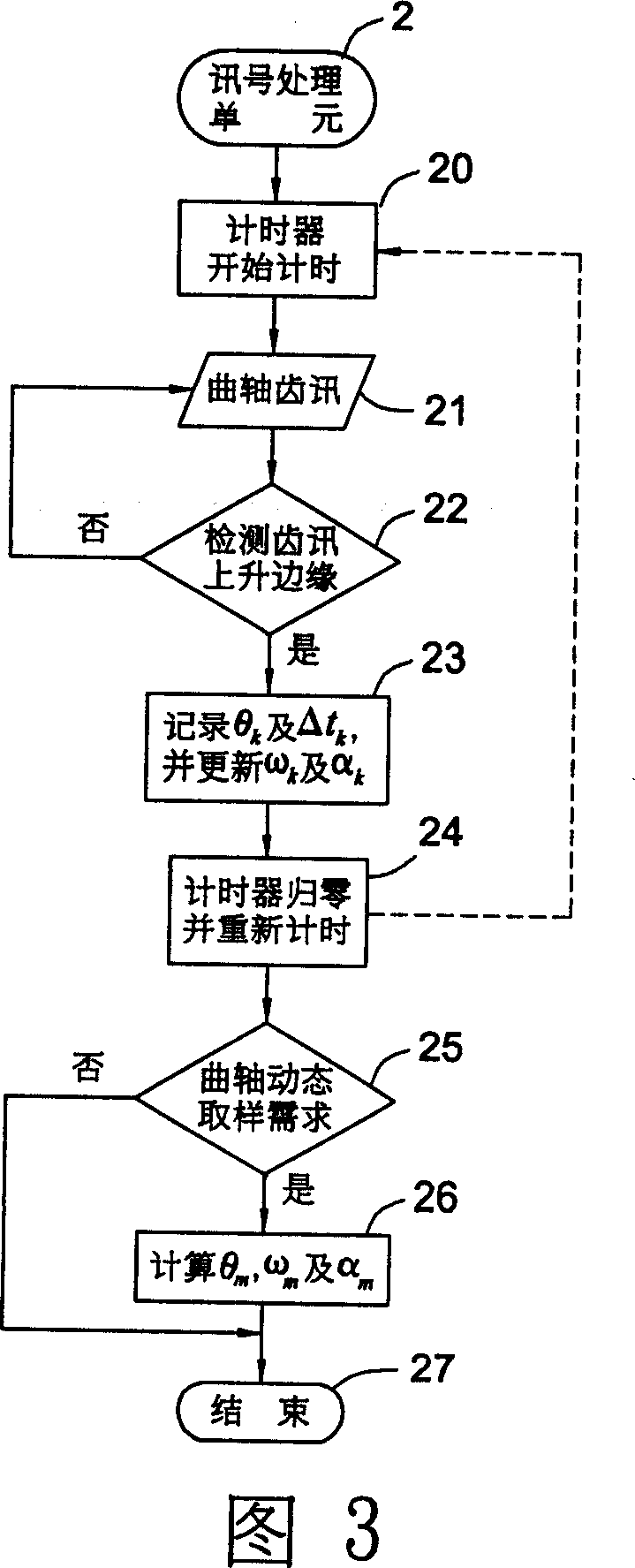

[0030] As shown in Figure 2 and Figure 3;

[0031] (1), use a signal processing unit 2, start timing 20 from the timer when the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com