Hydraulically-driven fan for cooling tower

A hydrodynamic and cooling tower technology, applied in the direction of reaction engine, hydroelectric power generation, machine/engine, etc., can solve the problem of low energy conversion efficiency, achieve low vibration and noise of tower body, reduce vibration, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

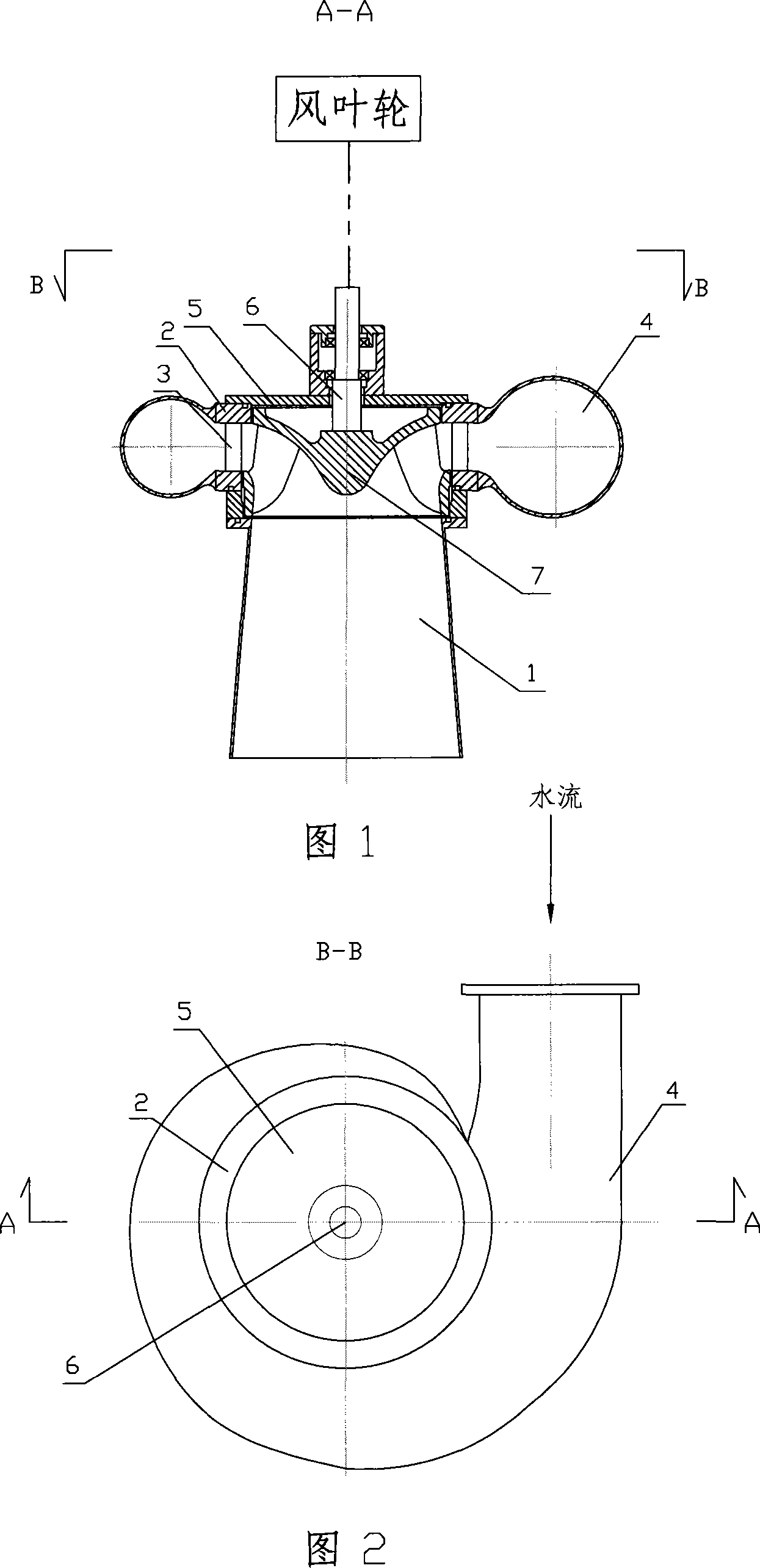

Embodiment 1

[0015] The device includes a wind impeller and a water turbine, the output shaft of the water turbine is connected with the rotating shaft of the wind impeller, and the water turbine is a reaction type water turbine, which includes a draft tube 1, and a seat ring 2 is fixedly connected to the upper end of the draft tube 1 , a water guide blade 3 is provided in the seat ring, a volute 4 is fixedly connected to the outer periphery of the seat ring 2, a cover plate 5 is provided on the upper surface of the seat ring 2, and a vertically inserted seat ring is installed at the center of the cover plate 5 through a bearing. The main shaft 6 in the center is equipped with a runner 7 of an impact water turbine at the lower end of the main shaft. The runner 7 can be installed in the axial flow turbine of the existing impact water turbine class according to the flow of water, the water head and the required efficiency and speed of the water turbine. Choose one of the runners of , Francis ...

Embodiment 2

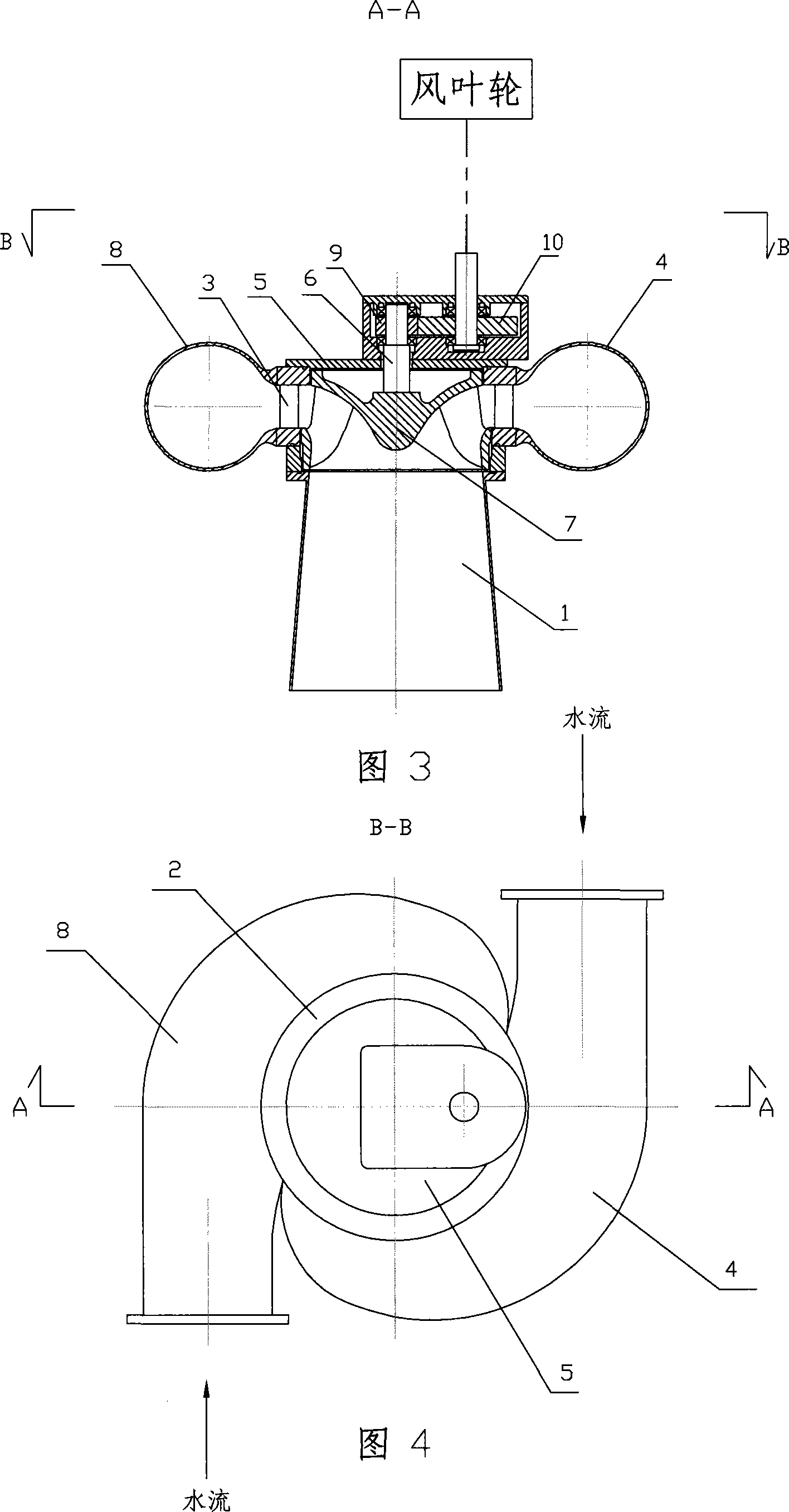

[0018] Referring to Figures 3 and 4, this example adds a volute 8 on the basis of Embodiment 1, that is to say, two volutes 4 and 8 are fixedly connected to the outer periphery of the seat ring 2, and the two volutes are connected with the seat ring 2 The axis is the axis and the axisymmetric reverse arrangement forms a bidirectional symmetrical water inlet distribution centered on the seat ring, as shown in Figure 4 . The two-way symmetrical water inlet distribution can make the runner 7 evenly stressed and rotate smoothly, greatly reducing the vibration of the water turbine, thereby minimizing the vibration and noise of the tower body during operation.

[0019] In addition, when the output speed of the water turbine can match the rated speed of the wind impeller, use the main shaft 6 of the water turbine to directly drive the wind impeller to rotate, as shown in Figure 1; when the two speeds cannot match, a gear governor can be used. For adjustment, as shown in Figure 3, wha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com