Method and apparatus for inspecting two-kind gas sensor array combination odour

A gas sensor and array technology is applied in the field of combined detection of odors and devices of two types of different gas sensor arrays, which can solve the problem of limited odor identification and achieve the effects of wide detection range, high accuracy and strong robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

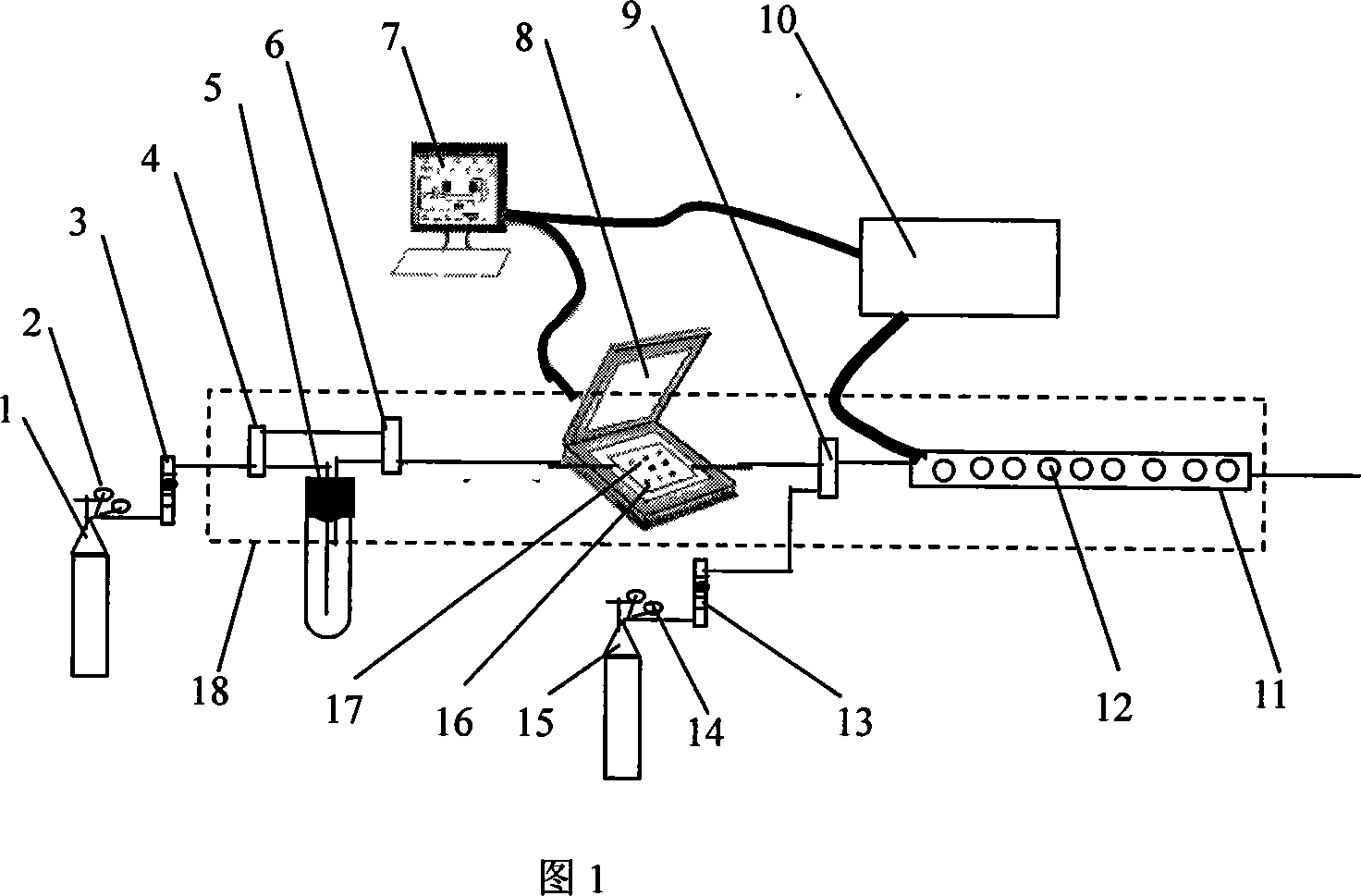

[0017] 1 is a schematic diagram of an odor detection device based on a metal oxide gas sensor array and a color-sensitive gas sensor array according to the present invention, mainly consisting of a nitrogen cylinder 1, a nitrogen pressure reducing valve 2, a nitrogen flow meter 3, a solenoid valve A4, and a gas generating chamber 5. Solenoid valve C6, computer 7, image acquisition device 8, solenoid valve B9, signal acquisition device 10, reaction chamber B11, metal oxide gas sensor array 12, oxygen flow meter 13, oxygen pressure reducing valve 14, oxygen cylinder 15, The reaction chamber A16, the color-sensitive gas sensor array 17, and the constant temperature device 18 are composed. The nitrogen in the nitrogen cylinder 1 is connected to the solenoid valve A4 through the nitrogen pressure reducing valve 2, the gas pipeline and the nitrogen flow meter 3; during detection, the solenoid valve A4 and the solenoid valve C6 control the nitrogen gas to pass through the gas generati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com