Potentiometer

A potentiometer and electrical connection technology, applied in the field of potentiometers, can solve the problems of expensive potentiometers, inflexibility, and expensive methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

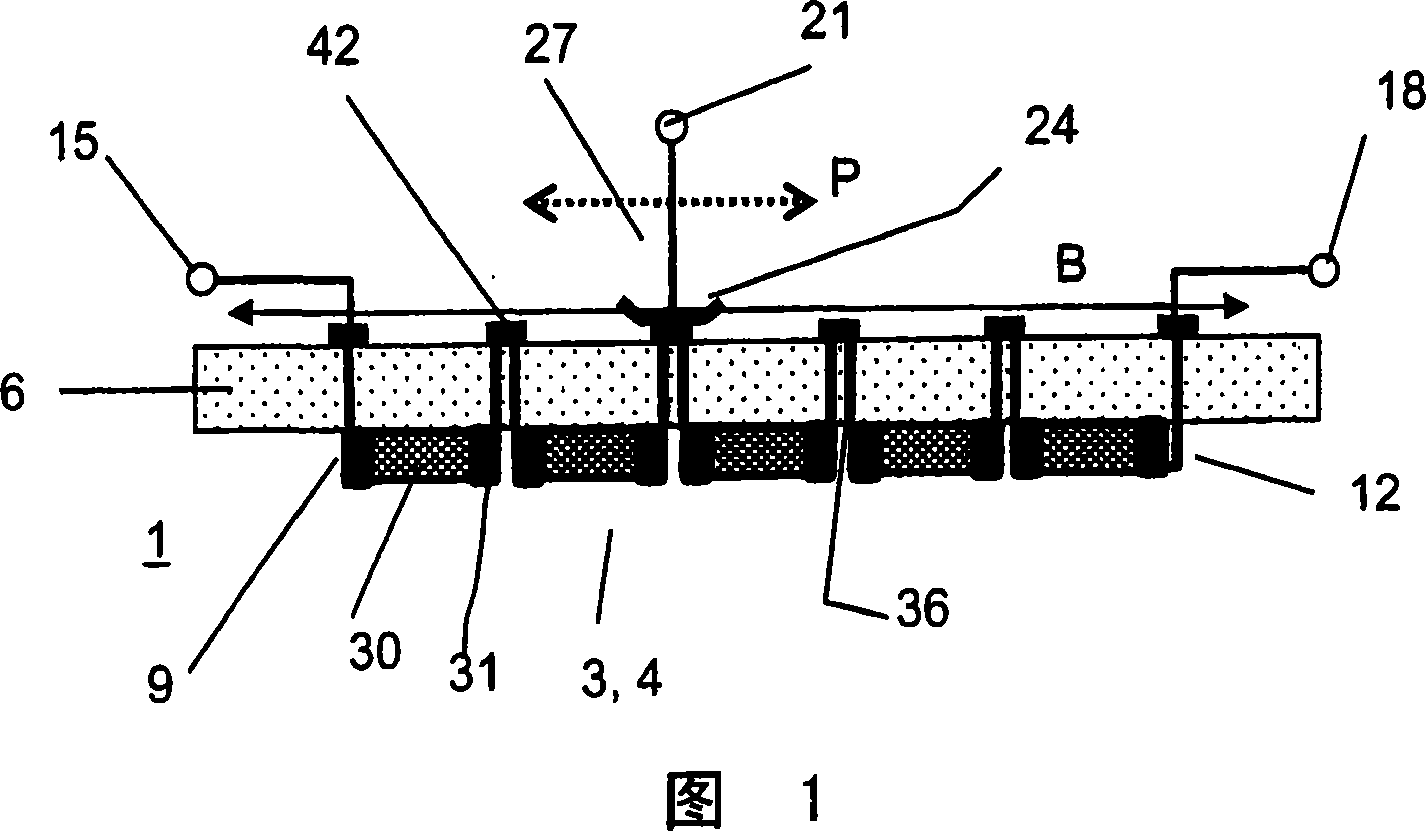

[0039] FIG. 1 shows a potentiometer 1 with a first potentiometer connection 15 , a second potentiometer connection 18 and a third potentiometer connection 21 . Arranged on the underside of the carrier plate 6 is an array 4 of resistive elements 30 in the form of a series circuit. The resistance element 30 is designed as an SMD component. They each carry a connecting piece 31 made of solder material at the ends of the cuboidal resistor body.

[0040]Electrically conductive leads lead from the connecting piece 31 of each resistor element 30 to the opposite side of the carrier plate 6 . There, the conductive leads of two adjacent resistance elements are electrically connected in electrical connection points 42 . The conductive leads thus form means for electrically connecting the components of the resistor array 3 with the sliding contacts within the adjustment range of the tap 27 . In this way, a series circuit of the resistor circuit 3 is produced between the first free end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com