Curve friction transportation automatic plastic container forming machines

A plastic container and molding machine technology, applied in the field of plastic machinery, can solve the problems of large heating loss, long heating channel, complex structure, etc., achieve the effects of shortening the heating circuit, high utilization rate of electric heat, and increasing heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

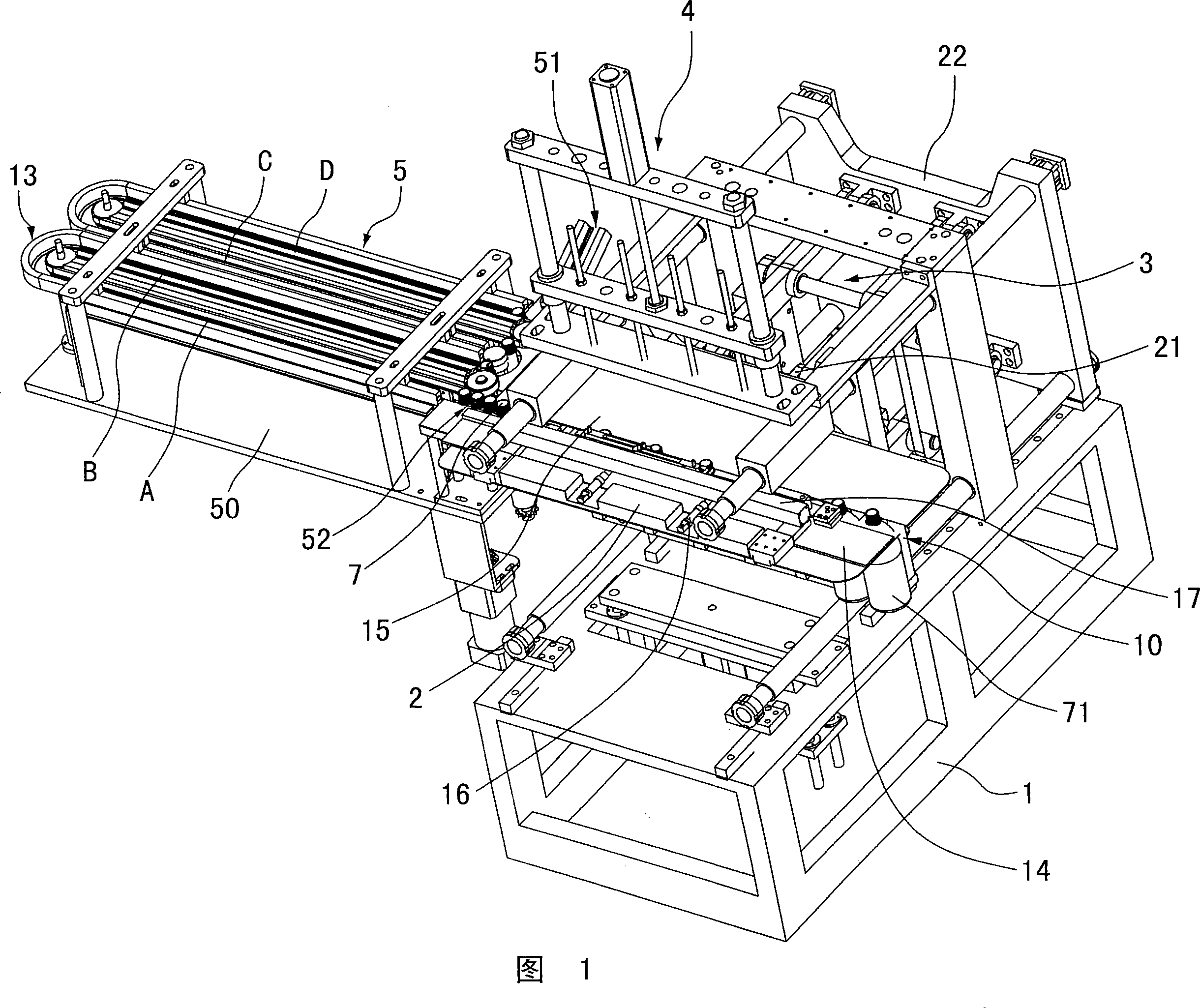

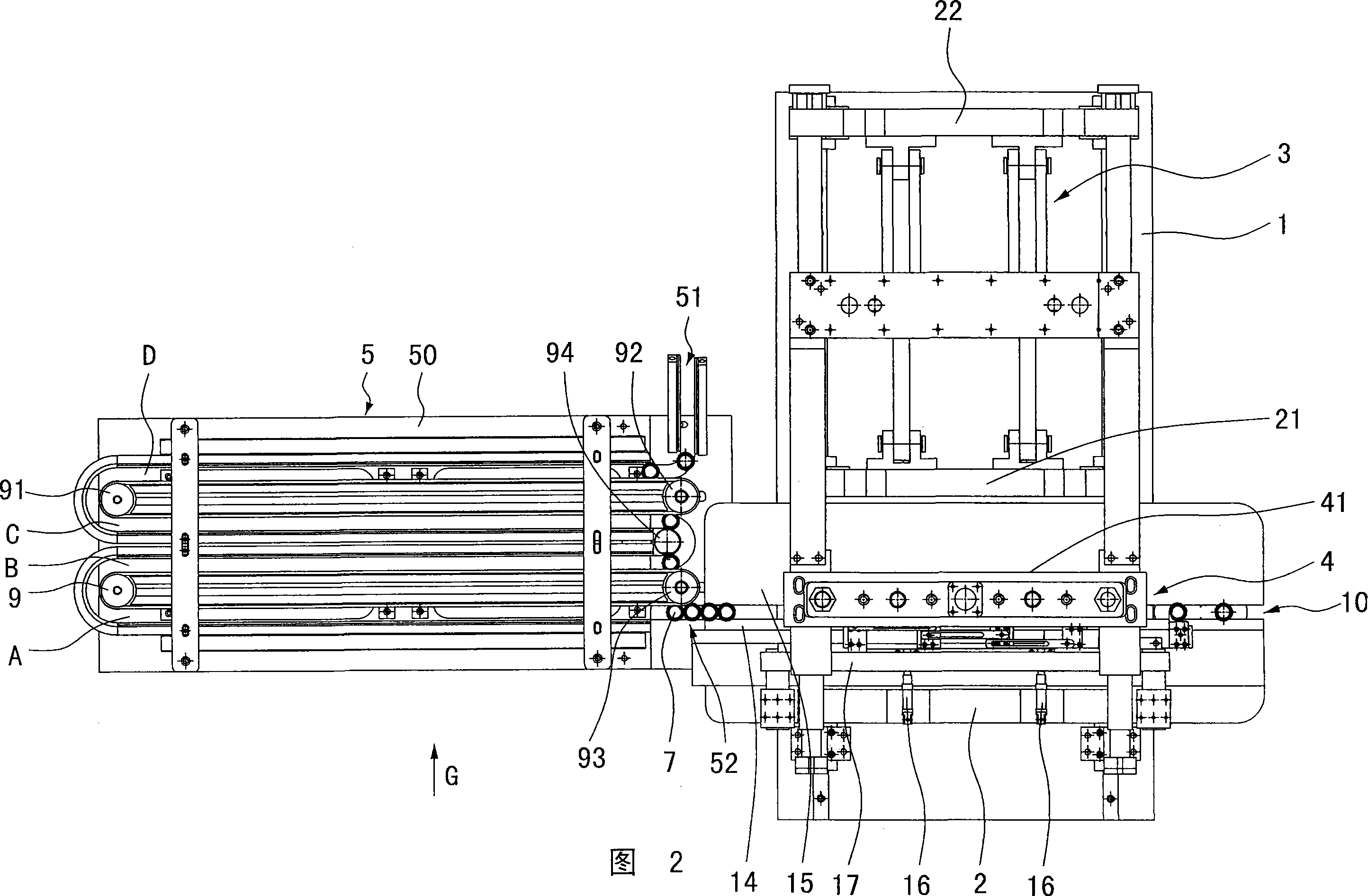

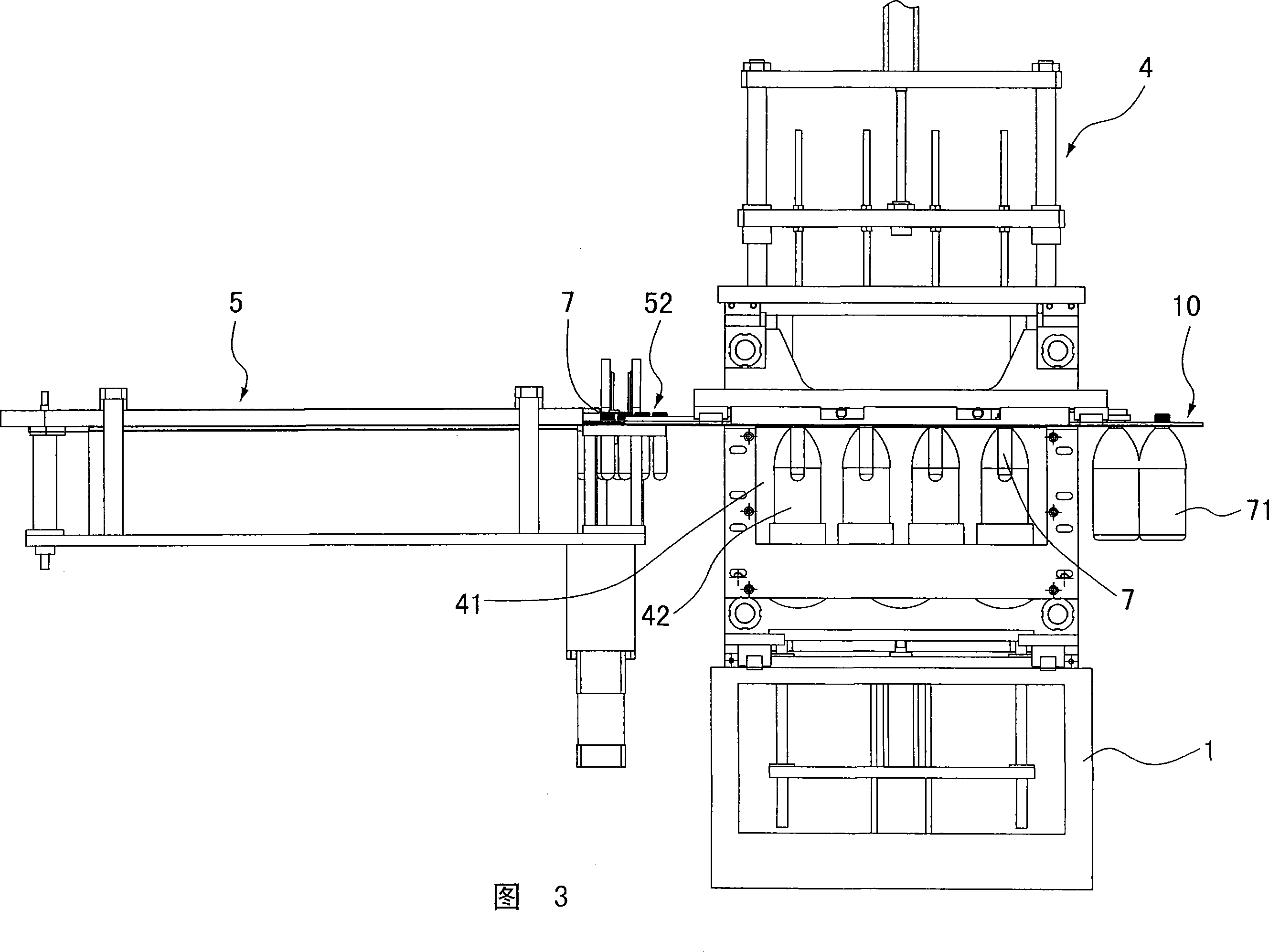

[0014] The present invention relates to the automatic plastic container molding machine of curved friction pipe, as shown in Fig. 1-Fig. Driven by the mold clamping mechanism 3, a mold 41 is installed in the template. There are mold cavities in the mold, generally two or more mold cavities, and a heating device 5 is installed on one side of the stretch-blow machine base. The heating device has a bracket 50. The plastic bottle tube conveying mechanism is installed in the support, and the conveying mechanism has a heating channel. There are hosting devices and conveying friction belts or friction chains on both sides of the heating channel. The hosting device and the friction belt or friction chain are in contact with the plastic bottle tube 7 facing upwards. , the friction belt or friction chain is driven by the transmission mechanism, and an electric heating device is installed at the lower part of the bracket corresponding to the heating track, which is characterized in that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com