Device and method for removing metal plate protection film

A metal sheet, protective film technology, applied in chemical instruments and methods, cleaning methods and utensils, thin material processing and other directions, can solve the problems of low production efficiency, unstable quality, cumbersome manual operation procedures, etc., to improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

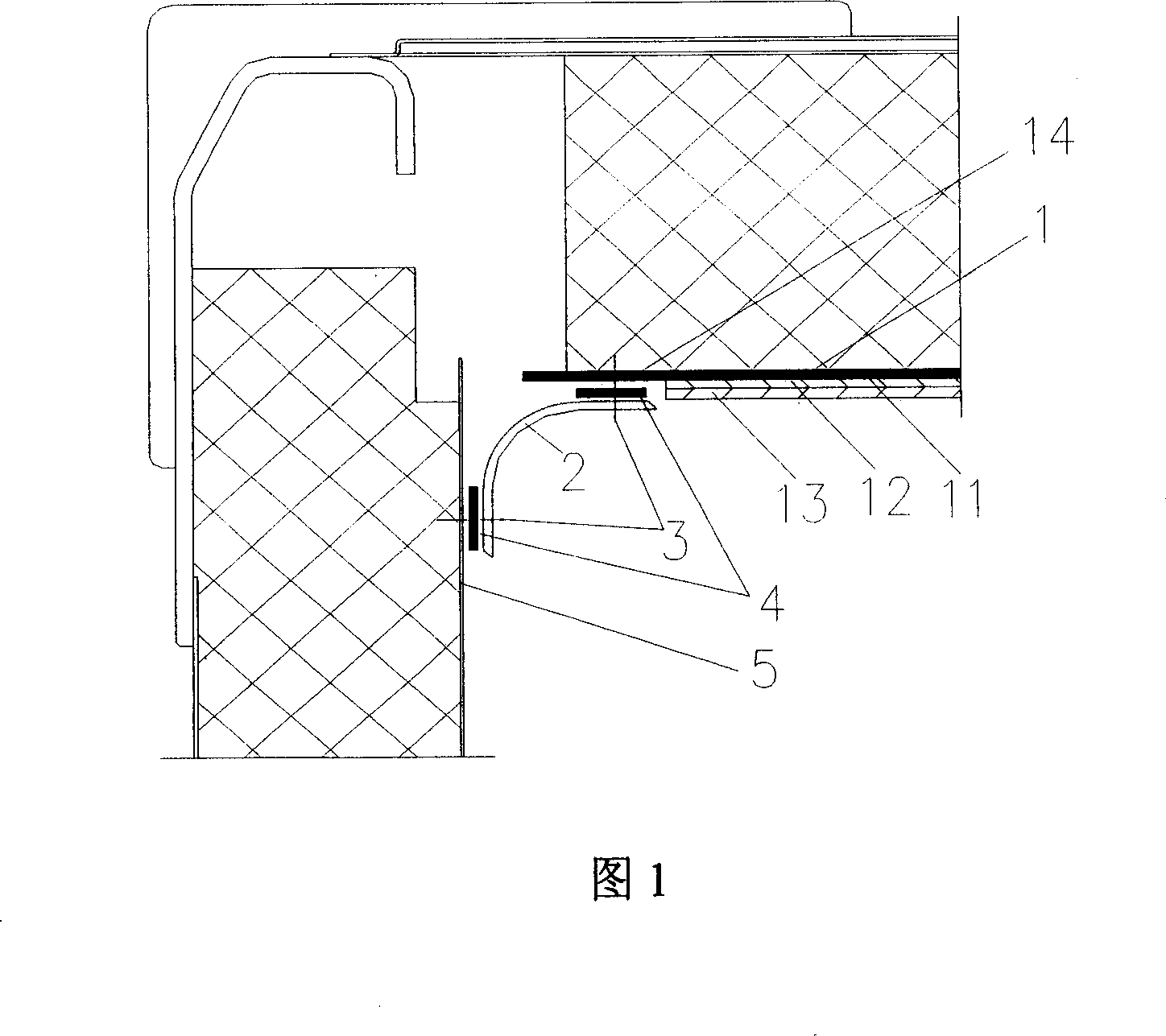

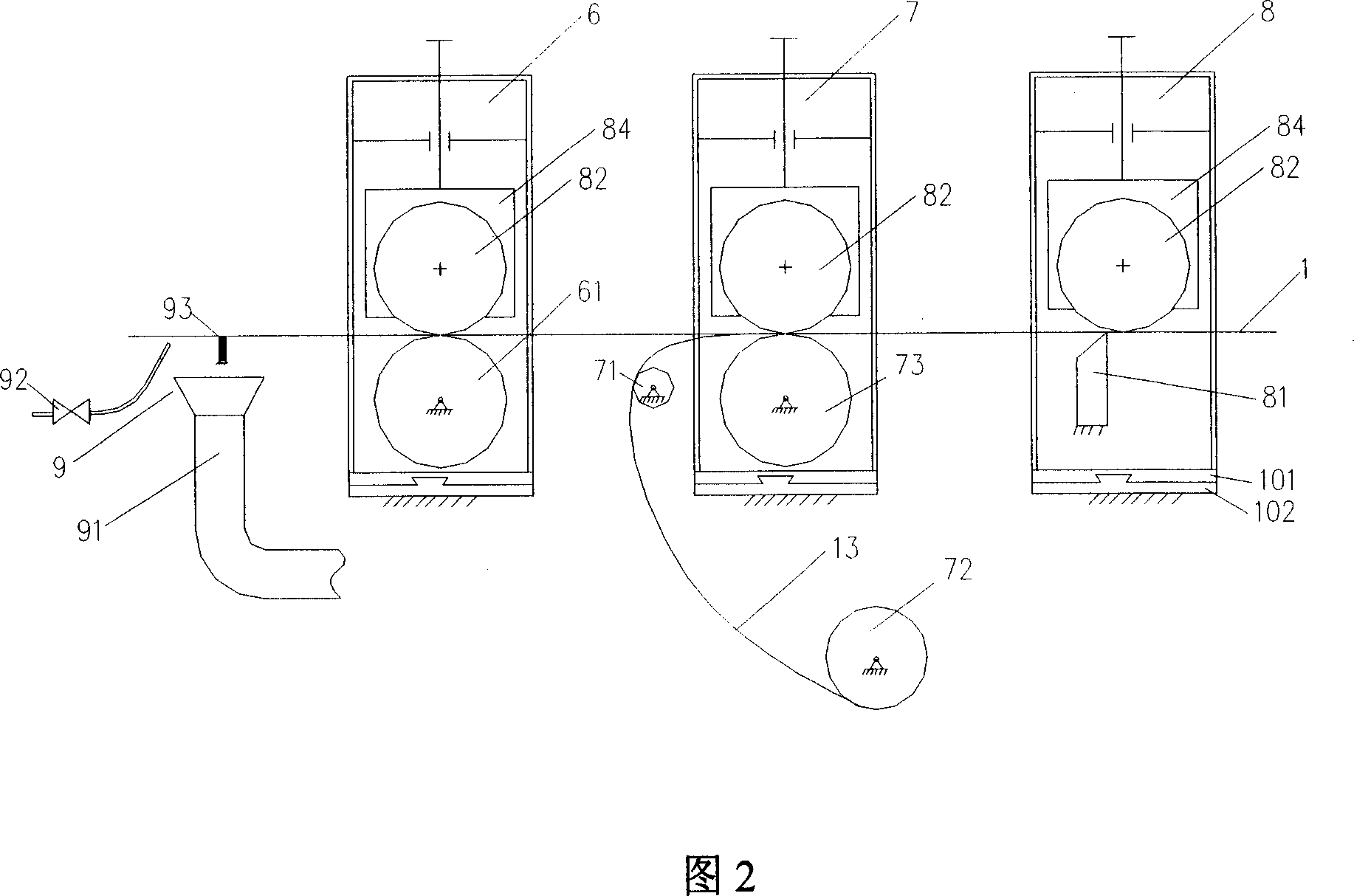

[0036] As shown in Figure 2, the present invention is used for removing the equipment of sheet metal protective film and is made up of following four parts:

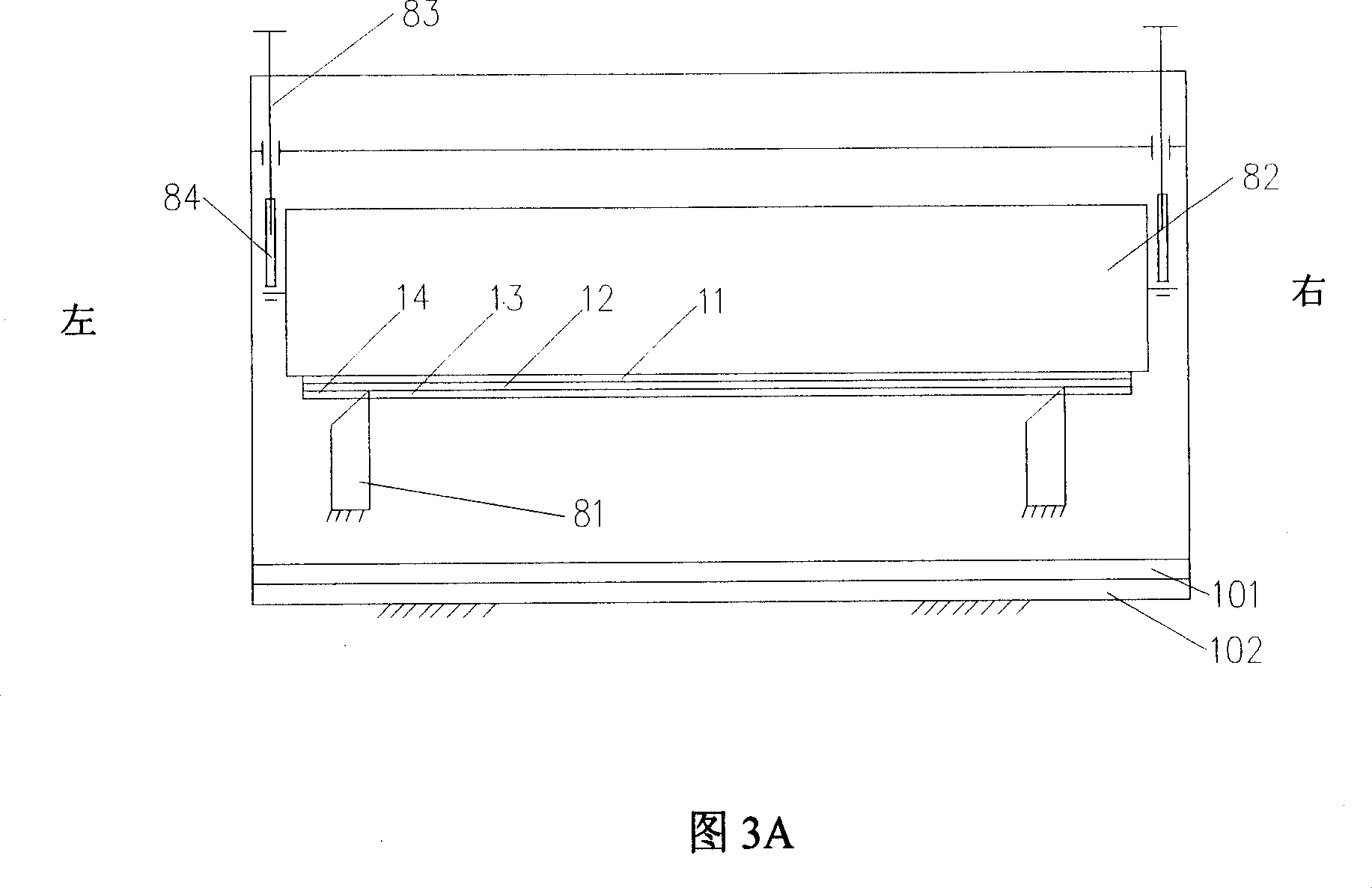

[0037] a. Film cutting device 8: it is composed of cutting knife 81 and upper pressure wheel 82. The upper pressure wheel 82 and blade 81 are installed on the frame, and their upper and lower positions are relative. The upper pressure wheel 82 can also be adjusted by screw nut 83 its up and down position.

[0038] b. Film rolling device 7: composed of an upper pressing wheel 82, a lower pressing wheel 73 and a film rolling mechanism 72, and is provided with a film breaking alarm mechanism 71. The upper pinch wheel 82 and the lower pinch wheel 73 are installed on the frame, and their up and down positions are relative, and the lower pinch wheel 73 is connected with the roll film disc 72 by a transmission (not shown in the figure), and this transmission can be a V-belt, a chain , crank linkage mechanism, gear transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com