Coke oven combustion chamber temperature metering system and metering method

A technology of temperature measurement and combustion chamber, which is applied in the direction of measuring heat, thermometer, measuring device, etc., can solve the problems of inability to realize the installation and failure of annular temperature measurement track, and achieve the effect of easy automatic management, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

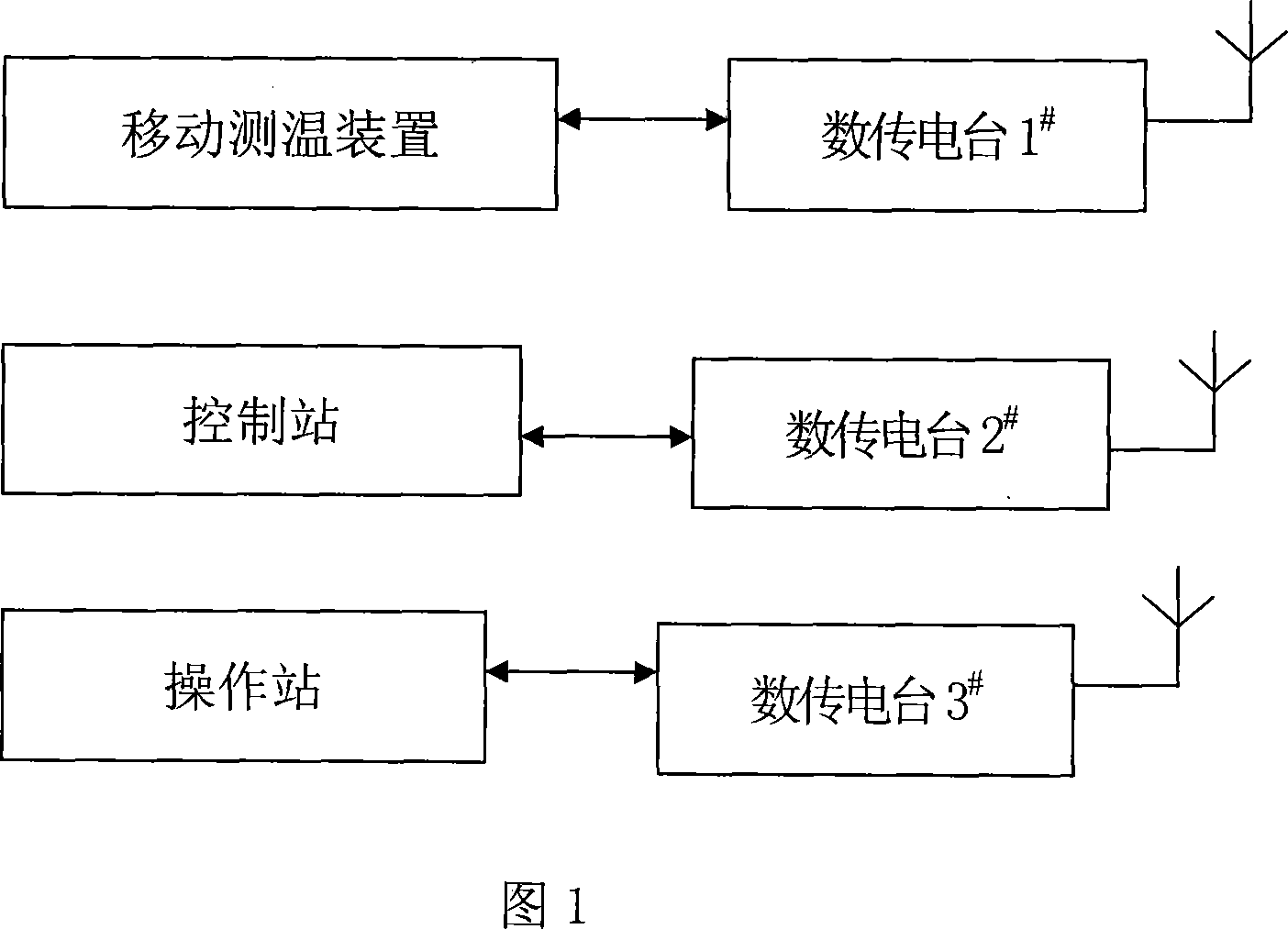

[0025] As shown in Fig. 1, the coke oven combustion chamber temperature measurement system of the present invention is composed of a control station, an operation station, and a mobile temperature measuring device, and the three parts exchange data and transmit information through a wireless data transmission station.

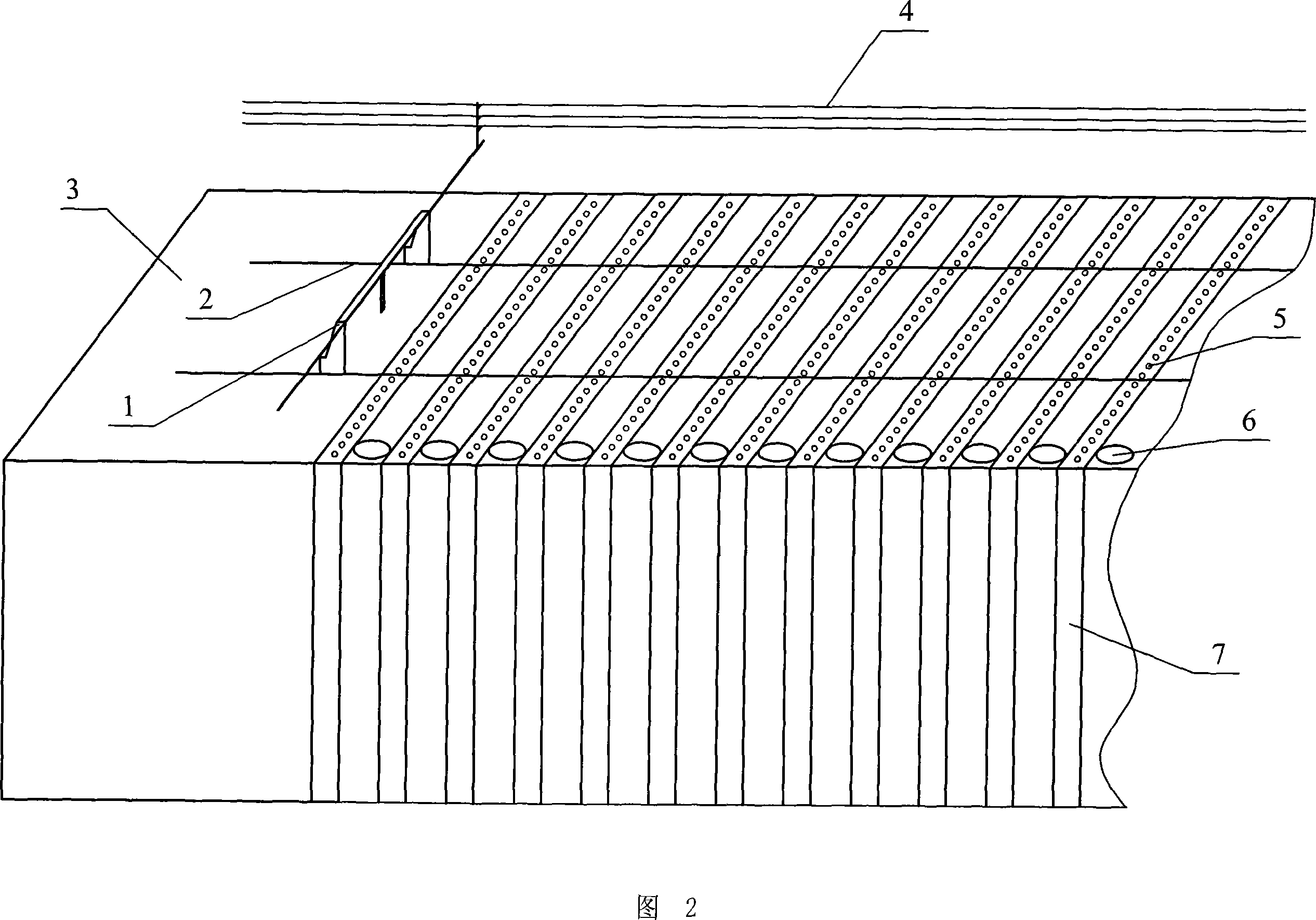

[0026] Figures 2 and 3 show that the present invention utilizes the roof rail 2 and the power supply rail 4 of the dust removal vehicle or the coal loading vehicle on the existing coke oven roof, and obtains power through the contact of the collector 9 with the power supply rail 4 to realize the movement. The automatic walking of the temperature measuring device 1 on the furnace top rail 2.

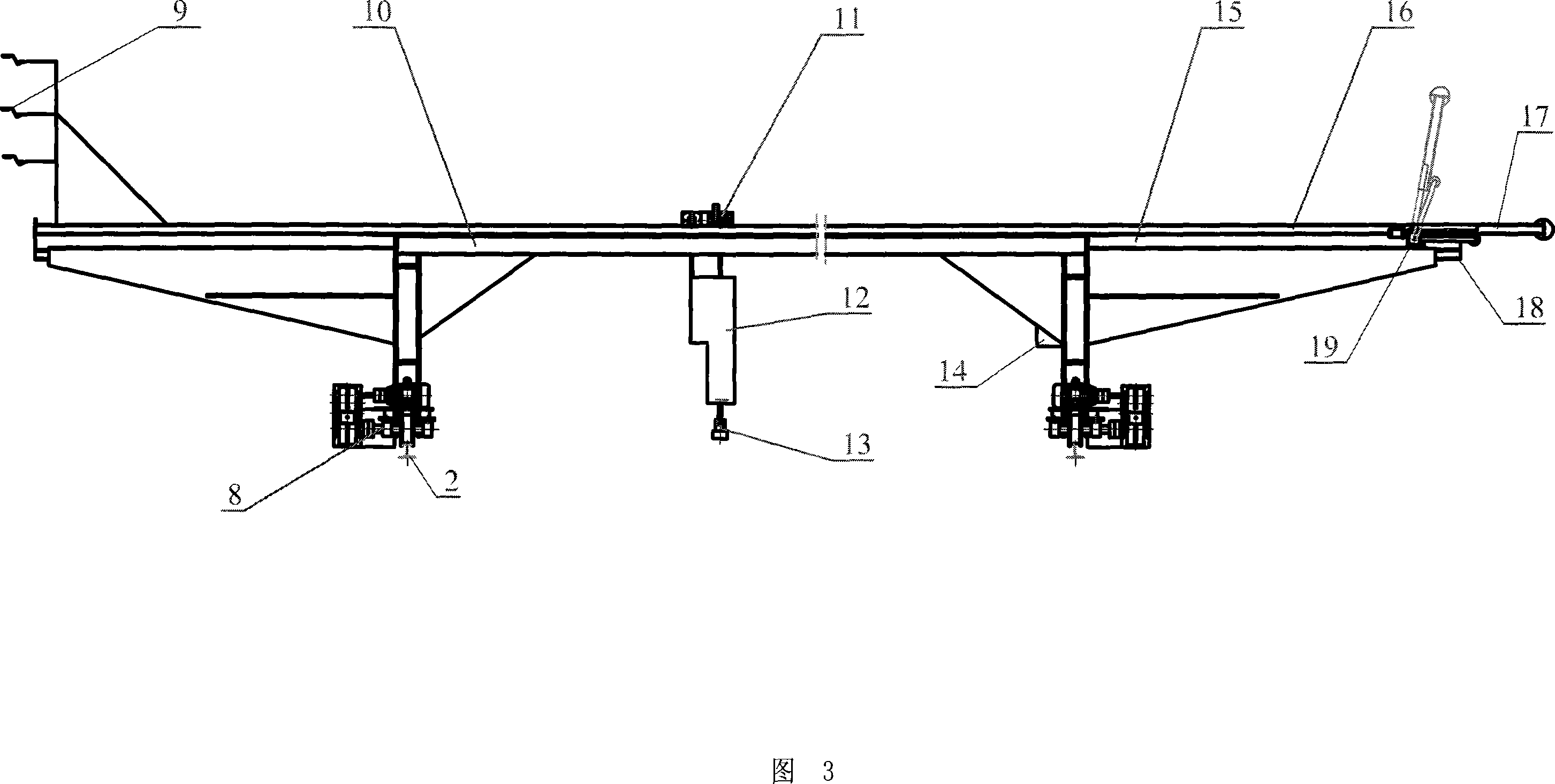

[0027] 3 and 4 show the overall structure of the mobile temperature measuring device 1 from two viewing directions. The I-shaped steel beam 10 is welded with the supporting steel plate 23 to form the supporting skeleton of the "∏" structure of the mobile temperature measur...

Embodiment 2

[0038] The present invention is used for the measurement method of coke oven combustion chamber temperature measurement system, utilizes existing furnace roof track 2 and power supply track 4 on the coke oven roof, and places mobile temperature measuring device 1 on the furnace roof track 2. The mobile temperature measurement The device 1 has three degrees of freedom of movement, walking along the furnace roof track 2; the measuring trolley 11 walking along the measuring track 16 or the folding track 17; and the up and down movement of the cover lifting electromagnet 27. By moving in these three directions, the measuring trolley 11 can be positioned above all the fire sight holes 5, and the fire sight hole cover 42 can be lifted accurately and reliably without changing the existing state of the fire sight hole cover 42, Move away, temperature measuring probe 35 is aimed at the vertical fire passage 43 in the fire hole 5 and carries out temperature measurement, and measurement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com