Confecting method of modern concrete and the mixing proportion thereof

A preparation method, concrete technology, applied in the direction of clay preparation equipment, mixing operation control, chemical instruments and methods, etc., can solve the problems of low preparation strength, low data accuracy, long test period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0211] Example 1. Use P.o42.5 grade cement (58Mpa), qualified sand, stone, fly ash S 1 , S 2 , High-efficiency water reducer, trial mix C110 plastic high-strength concrete.

[0212] 1. Determine the design strength of concrete: R s 28 =1.15×100=115MPa plastic high-strength concrete

[0213] 2. Determine the particle diameter and apparent density of concrete constituent materials:

[0214] Gravel particle diameter 05-10mm; fineness modulus greater than 2.9 medium sand; cement specific surface area 4.3-10.6 times fly ash S 1 , S 1 The specific surface area is 4.3-10.3 times more than fly ash S 2 . Px=2750, Py=2700, P c =2680,PS 1 =PS 2 =1900

[0215] 3. Determine the dosage of the main component materials for preparing nearly unit volume (close to one cubic meter) concrete:

[0216] e 集 =40%, A=0.8, W / C=0.26

[0217] X=2750×(0.8-0.4)=1100kg

[0218] Y=2700×(1-0.4)×0.4=648kg

[0219] C 灰 =2680×(1-0.4)×0.4 2 =257kg

[0220] C=C 胶 +C 灰 =138+257=395kg

[0221] ...

example 2

[0231] Example 2. Prepare C50 self-compacting concrete with P.o32.5 grade cement (42.1Mpa), high-efficiency water reducer, and qualified sand and gravel.

[0232] 1. Determine the design strength of concrete: R s 28 =58Mpa self-compacting concrete

[0233] 2. Particle diameter and apparent density of concrete constituent materials: gravel particle diameter 05-10mm; fineness modulus greater than 2.7 medium sand; Px=2750, Py=2700, Pc=2650;

[0234] 3. Determine the dosage of the main constituent materials for the preparation of nearly unit volume concrete:

[0235] e 集 =50%, A=0.8, W / C=0.28;

[0236] X=2750×(0.8-0.5)=825kg

[0237] Y=2700×(1-0.5)×0.5=675kg

[0238] C 灰 =2650×(1-0.5)×0.5 2 =331kg

[0239] C=C 胶 +C 灰 =138+331=469kg

[0240] W=469×0.28=131.3kg

[0241] 4. Concrete mix volume: V 砼 =0.3+0.5×0.5+469 / 2650+0.1313=0.858m 3 ;

[0242] Concrete porosity: e 砼 = 131.3 / 858 = 15.3%;

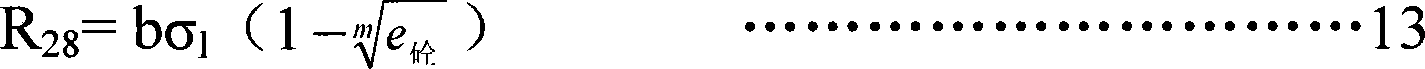

[0243] Five. Concrete preparation strength: m=log 1.9 15.3 = 4.24996,

[...

example 3

[0252] Example 3. Prepare C60 plastic permeable concrete with P.o42.5 grade cement (50.1Mpa), high-efficiency water reducer, qualified sand and gravel, ground mineral powder (fly ash), and gasoline. The ambient temperature is above 20°C and water seepage The rate is about 0.001 cm / s.

[0253] 1. Determine the design strength of concrete: R s 28 =69Mpa permeated concrete

[0254] 2. Particle diameter and apparent density of concrete constituent materials:

[0255] Crushed stone particle diameter 05-10mm; fineness modulus greater than 2.7 medium sand; cement specific surface area 4.3-10.3 times the finely ground mineral powder S 1 , S 1 The specific surface area is more than 4.3 times the ground fine mineral powder S 2 . Px=2750, Py=2700, Pc=2680, PS 1 =PS 2 =1900,P H =660

[0256] 3. Determine the amount of the main constituent materials of the concrete near unit volume:

[0257] e 集 =40%, A=0.8, W / C=0.28,

[0258] X=2750×(0.8-0.4)=1100kg

[0259] Y=2700×(1-0.4)×0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com