Drilling fluid treatment system

A technology for processing systems and drilling fluids, which is used in earth-moving drilling, flushing wells, wellbore/well components, etc. The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

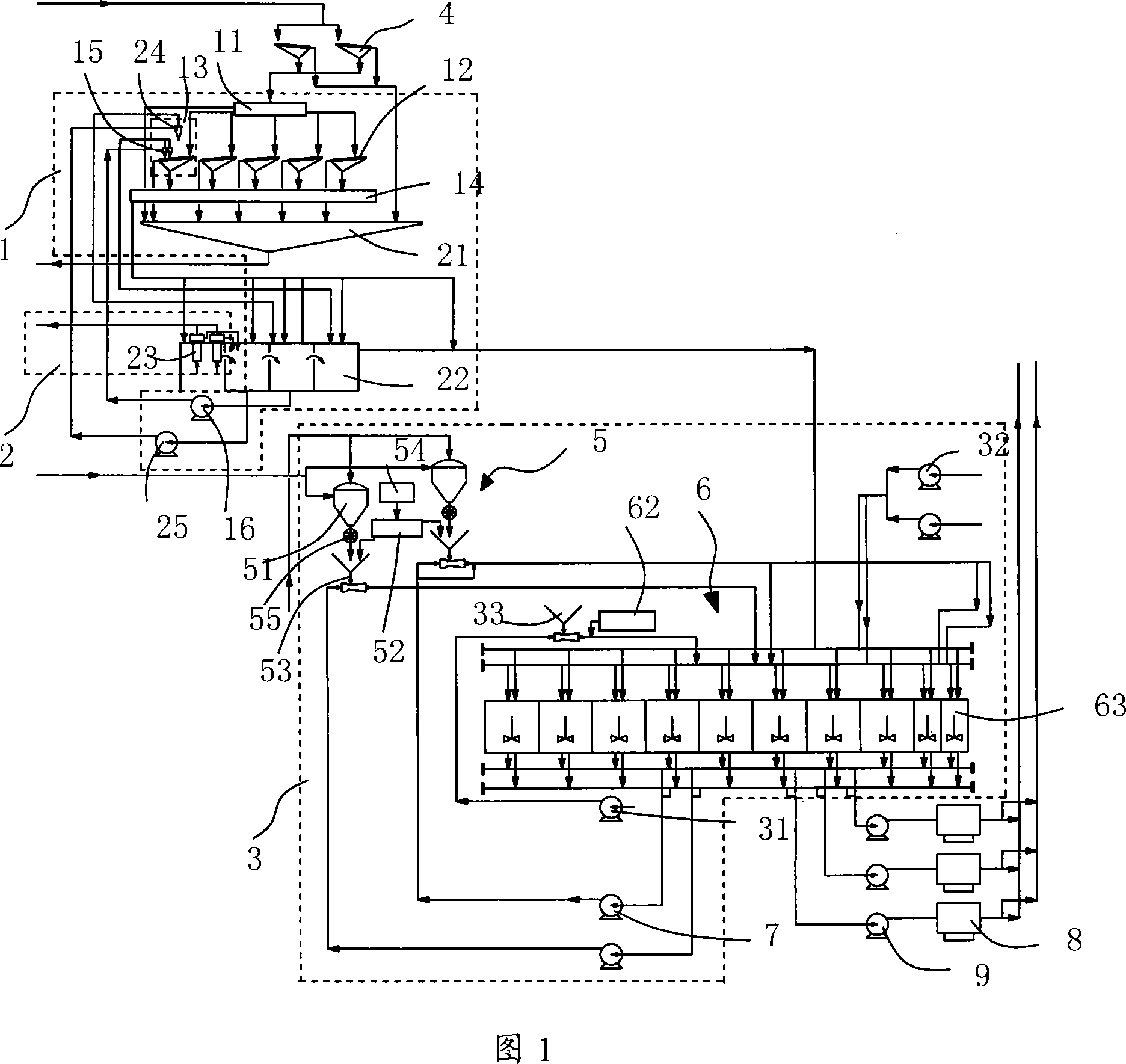

[0012] As shown in Figure 1, the present invention includes: a silt removal part 1, a degassing part 2 and a recombination part 3, and the drilling fluid returned from the wellhead passes through the silt removal part 1 and the degassing part 2 respectively to remove drilling cuttings such as mud and sand After mixing with natural gas, ash and liquid chemicals are compounded in the compounding part 3; a mud scraper 4 for removing sticky mud cakes in the drilling fluid is also provided upstream of the mud and sand removal part 1, as described below in detail.

[0013] In Fig. 1, the desilting part 1 includes: a flow divider 11, a vibrating screen 12, a mud cleaner 13, a desilter 15, a desander 24, a mud return tank 14, a desilter pump 16, a sand discharge tank 21, a settling Sand pool 22, sand removal pump 25. The mud scraper 4 is arranged at the upstream of the desilting part 1, that is, at the upstream end of the flow divider 11, like this, the mud returned from the wellhead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com