Concrete transfer pump energy-saving control method

A technology of concrete delivery pump and energy-saving control, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problem of high diesel oil consumption, and achieve the effect of reducing work intensity, prolonging service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

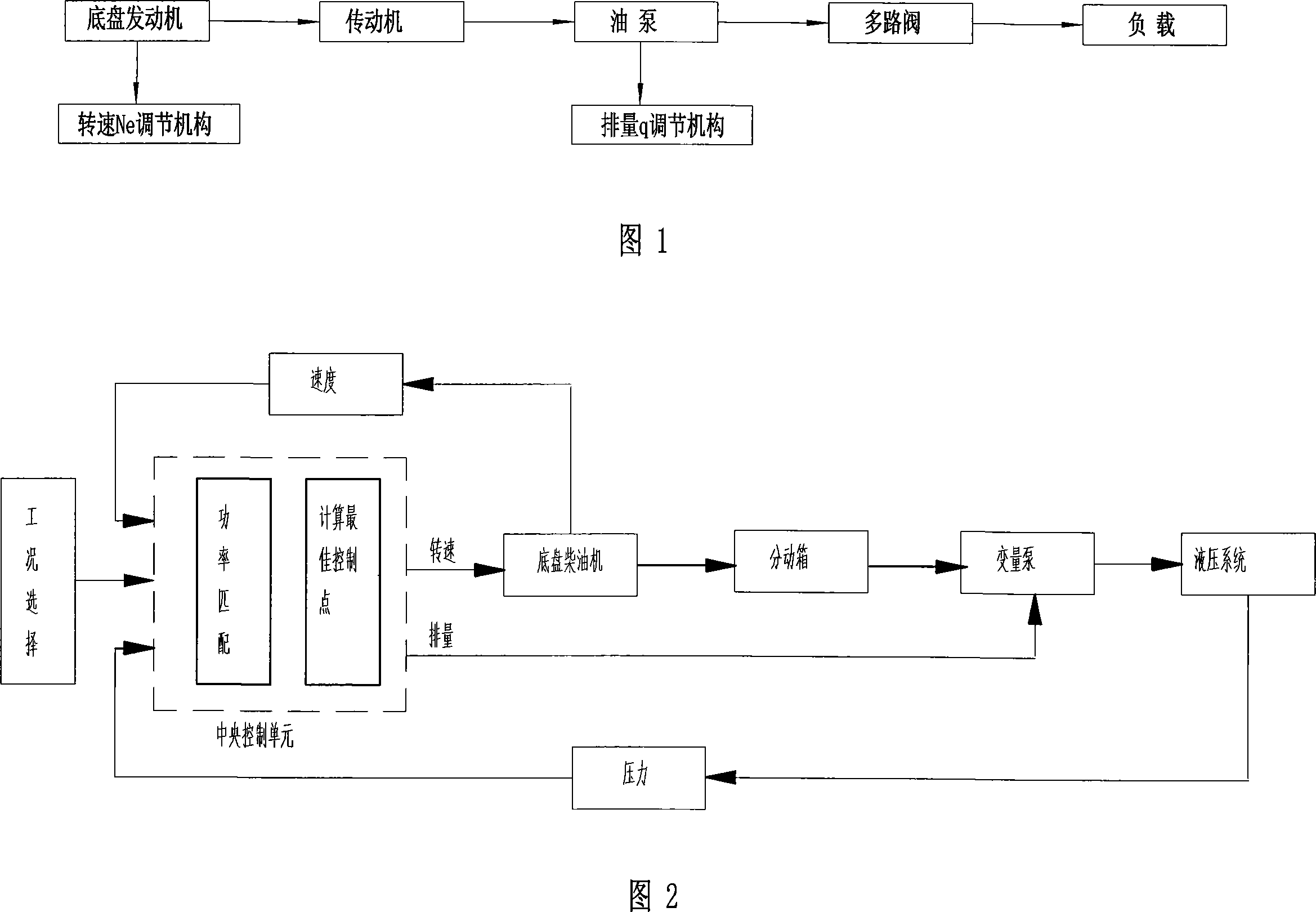

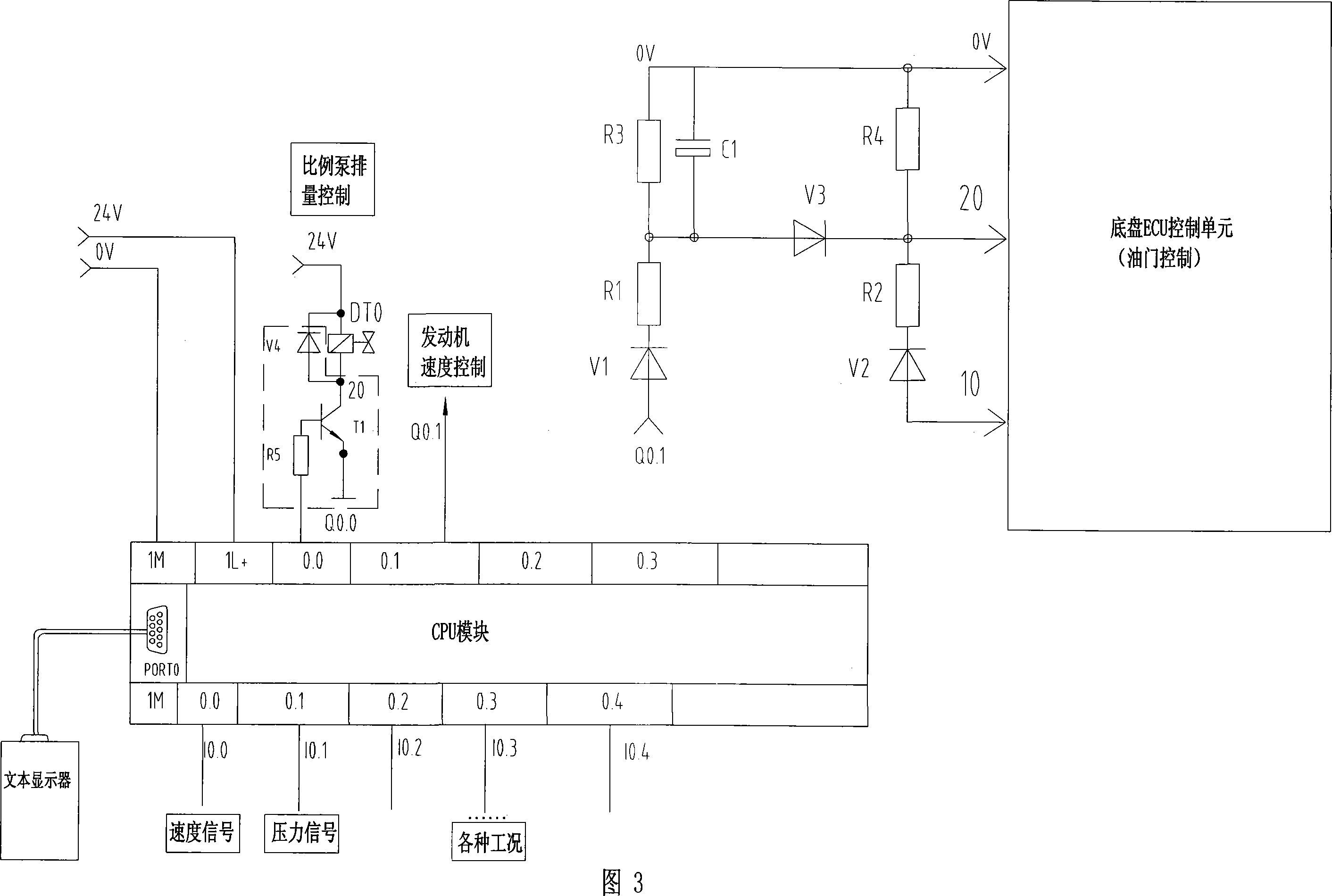

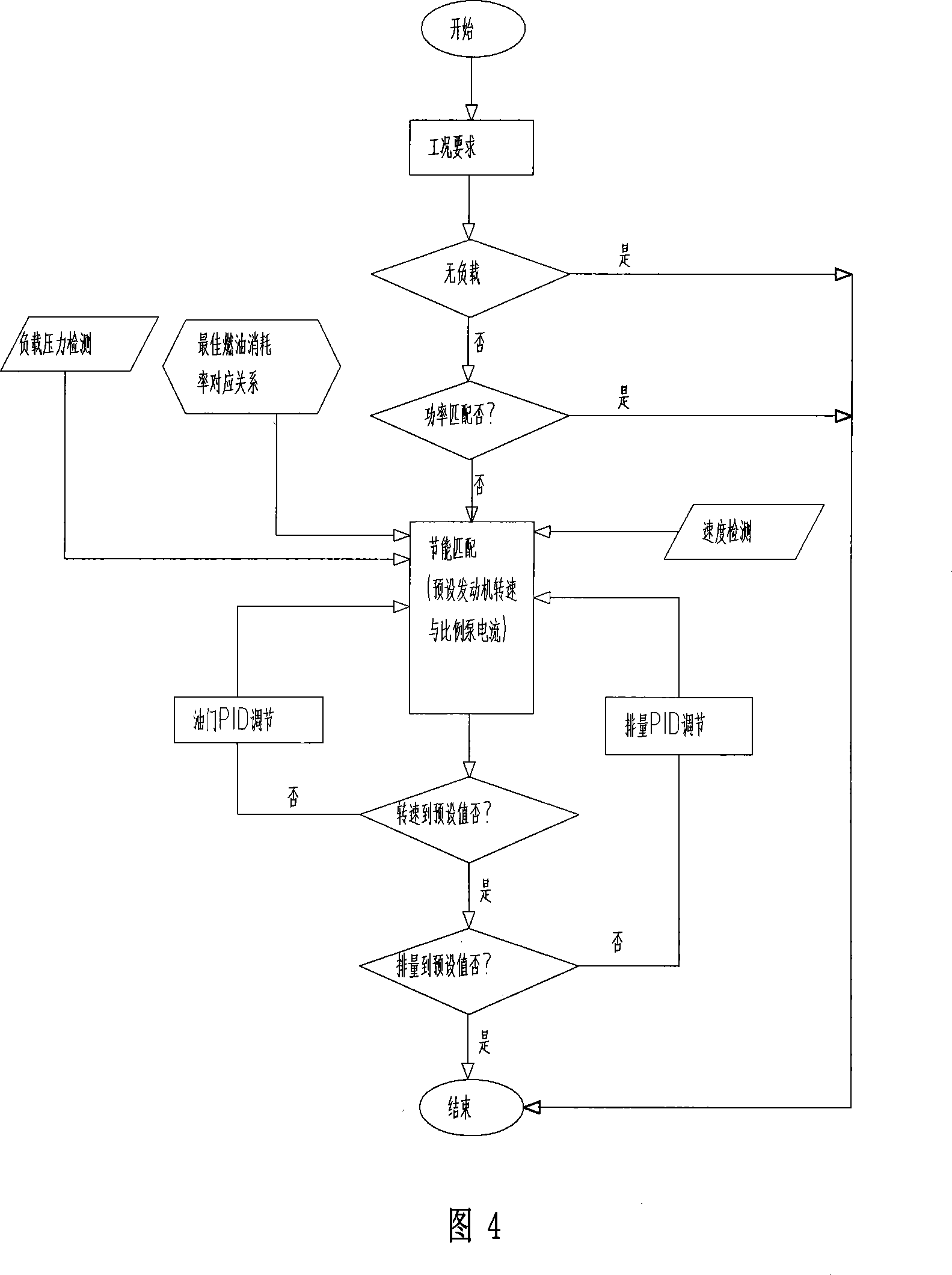

[0028] According to the energy-saving control method of a concrete delivery pump of the present invention, according to the working conditions of the construction site, the central control unit is controlled by the load pressure P L Based on the matching relationship with the engine power, the engine speed ne and the oil pump current I are preliminarily calculated. The control signal of the engine speed ne is transmitted to the chassis engine of the concrete delivery pump through the central control unit, and the speed is determined according to the current speed fed back by the chassis engine. The closed-loop adjustment makes the current speed n consistent with the set speed ne; the chassis engine transmits power to the oil pump through the transmission mechanism (transfer case), and the control of the oil pump current I is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com