Valve capable of draining water

A technology for drainage and water interception, which is applied in the direction of water supply devices, water supply main pipelines, water supply pipeline systems, etc., to achieve the effects of increasing the drainage path, shortening the drainage path, and increasing the drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

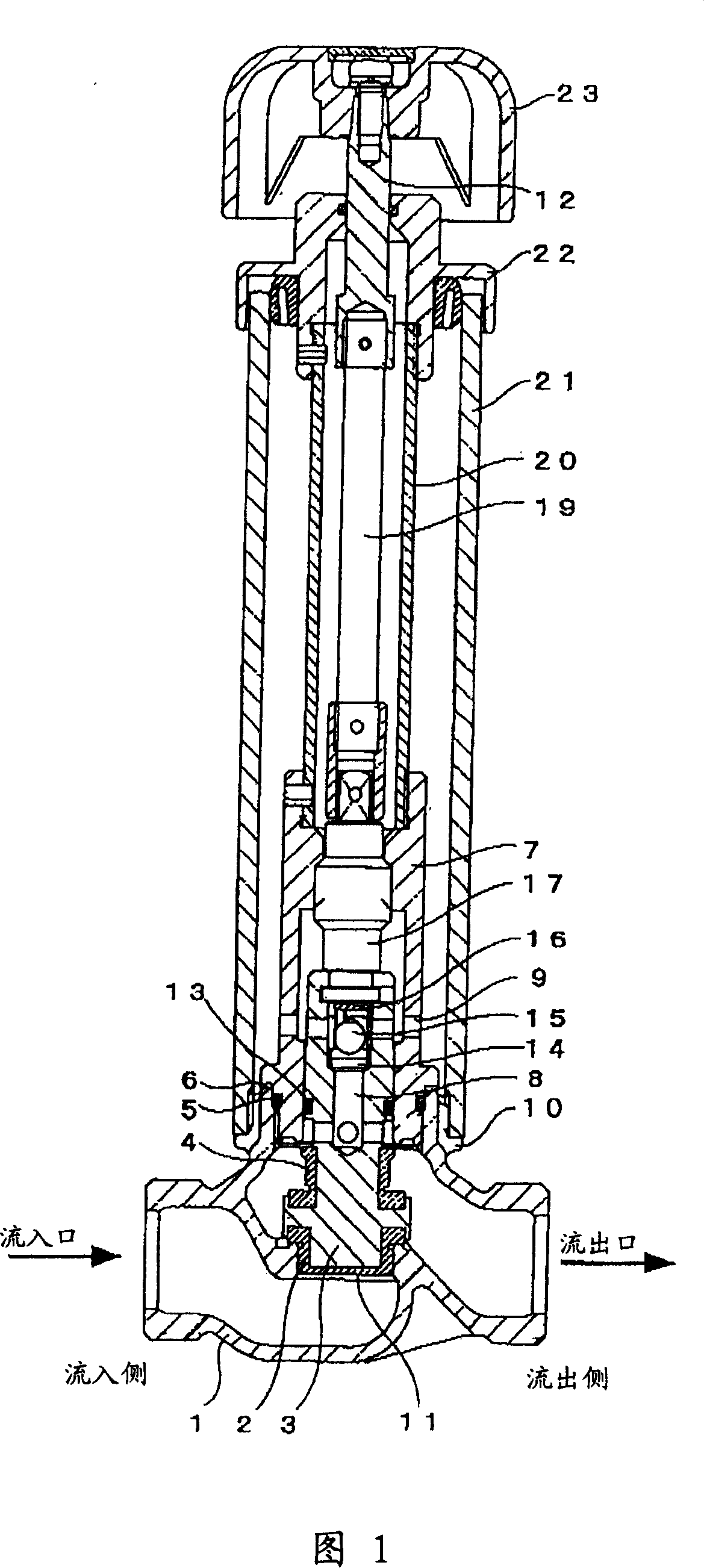

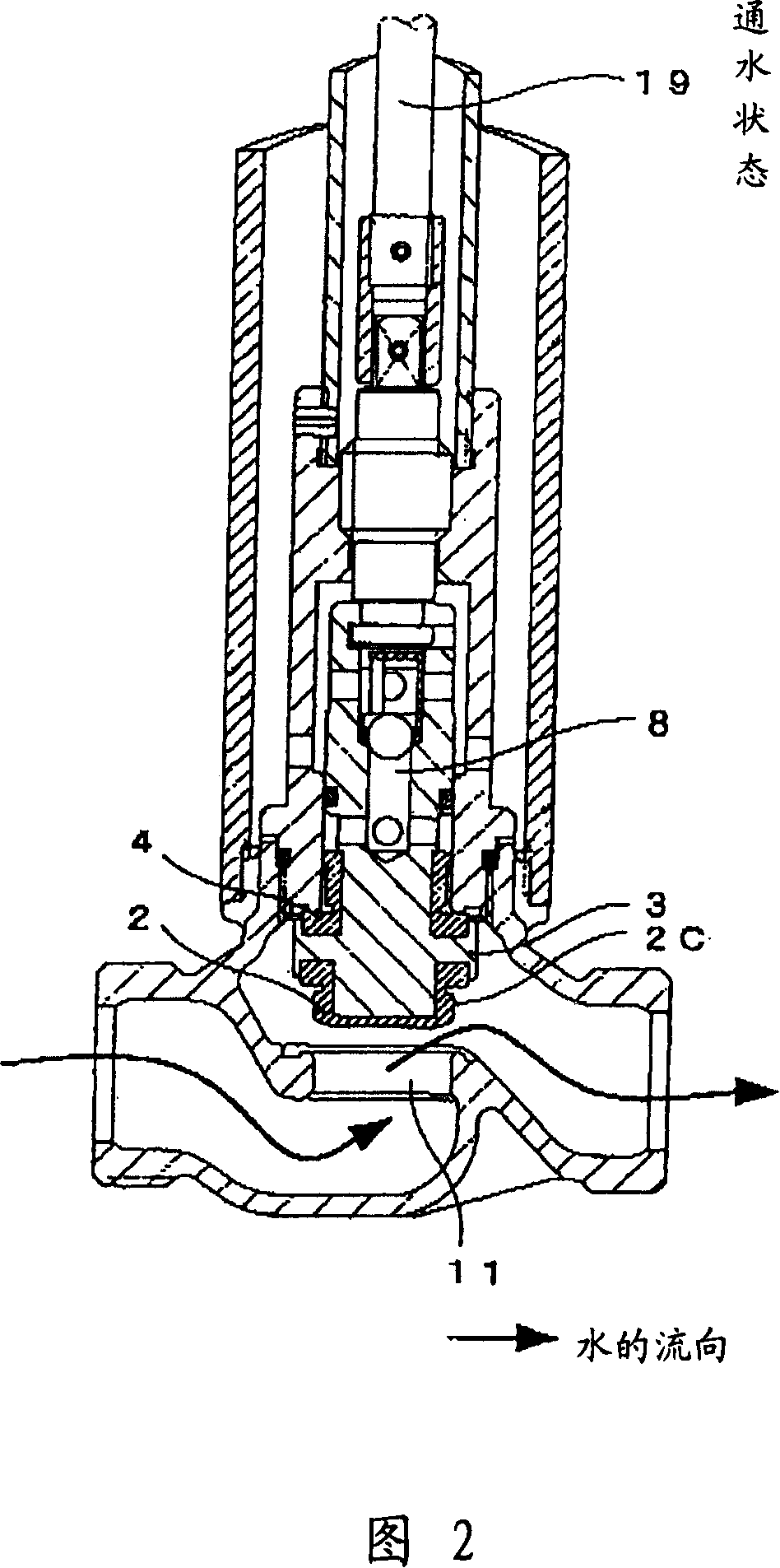

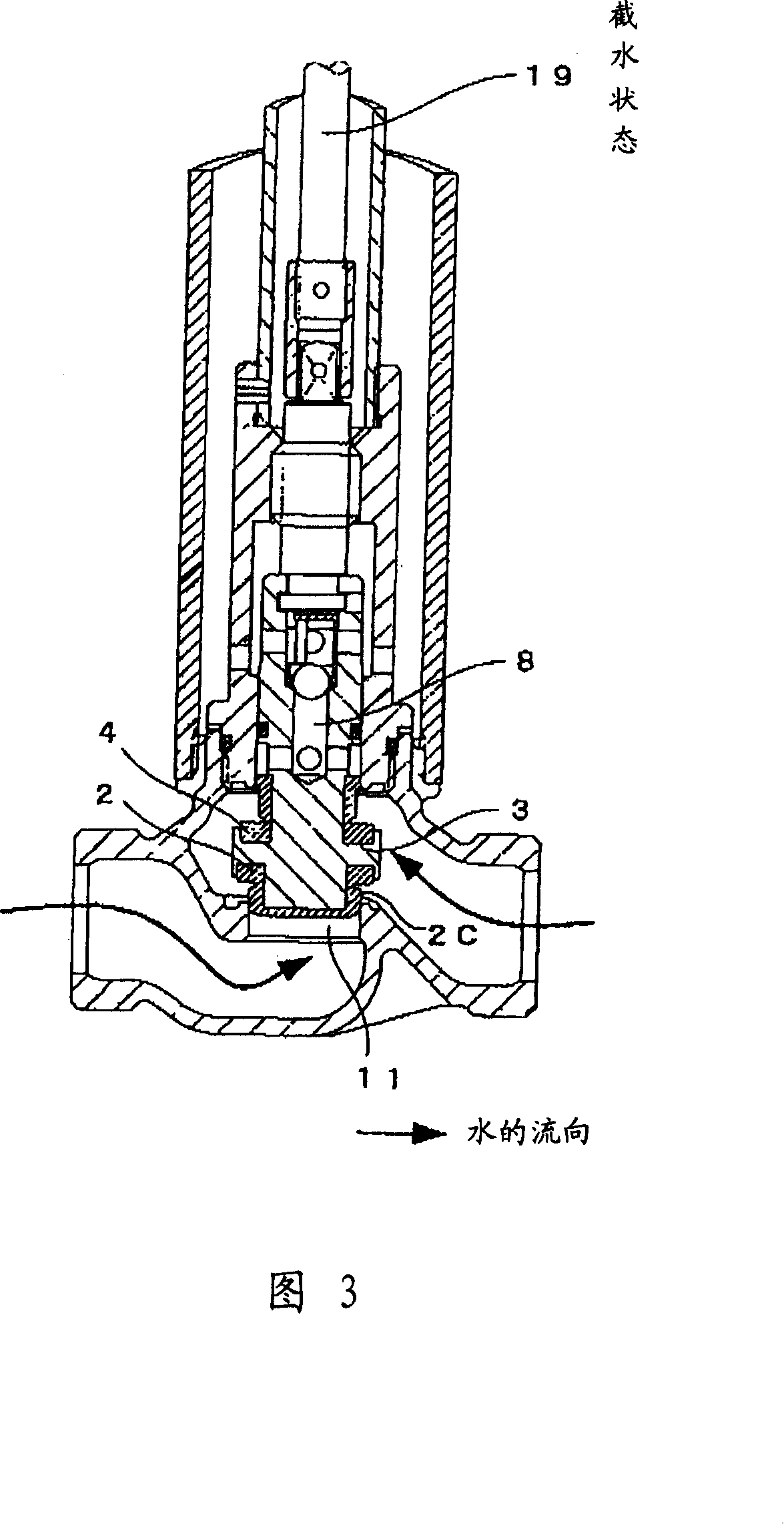

[0027] First, the first embodiment will be described with reference to Figs. 1 to 7.

[0028] Fig. 1 is a front cross-sectional view showing a drain hydrant of the first embodiment of the present invention, and Fig. 2 is a partial front cross-sectional view of the drain hydrant of Figure 1, and Fig. 3 is a partial front cross section of the drain roller cut in Fig. 1. Fig. 4 is a partial front cross section, and Fig. 5 (a), Fig. 5 (b), and Fig. 5 (c) are a cut-off sem in accordance with a first embodiment of the present invention for the first embodiment of the present invention. Positive cross-sectional view of the pieces, Figure 6 (a), Figure 6 (b), Fig. 6 (c) is a front cross-sectional view of the ball guide for the drain hydrants of the first embodiment of the present invention. As shown in the figure and bottom, Fig. 7 (a), Fig. 7 (b) is a front cross-sectional view of a lip gasket for the drain hydrants and the above view of the first embodiment of the present invention. The...

no. 2 example

[0037] Next, the second embodiment will be described with reference to FIGS. 8 and 9.

[0038] Figure 8 is a front cross-sectional view of the drain plug of the second embodiment of the present invention, Figure 9 (a), Figure 9 (b), Figure 9 (c) is the second embodiment of the present invention for the interception of the drain plug The front cross-sectional view, top view and bottom view of the piece. This embodiment has the feature of installing a safety valve that releases the abnormal pressure generated on the outflow side on the interceptor.

[0039] The drain plug of this embodiment has a plug main body 1, an operation lever 19 of the operation plug main body 1, and a handle 23 that drives the operation lever 19 up and down. The plug main body 1 has: an inflow-side inflow port, an outflow-side outflow port formed on the side of the plug main body 1, a water passage having a water through hole 11 provided between the inflow port and the outflow port, and is detachably fitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com